Non-traditional machining method of RV cycloid gear

A cycloid gear and processing method technology, applied in the field of gear processing, can solve the problems of high processing cost, low efficiency, increase the manufacturing cost of the reducer, etc., and achieve the effects of reducing processing cost, reducing production cost and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

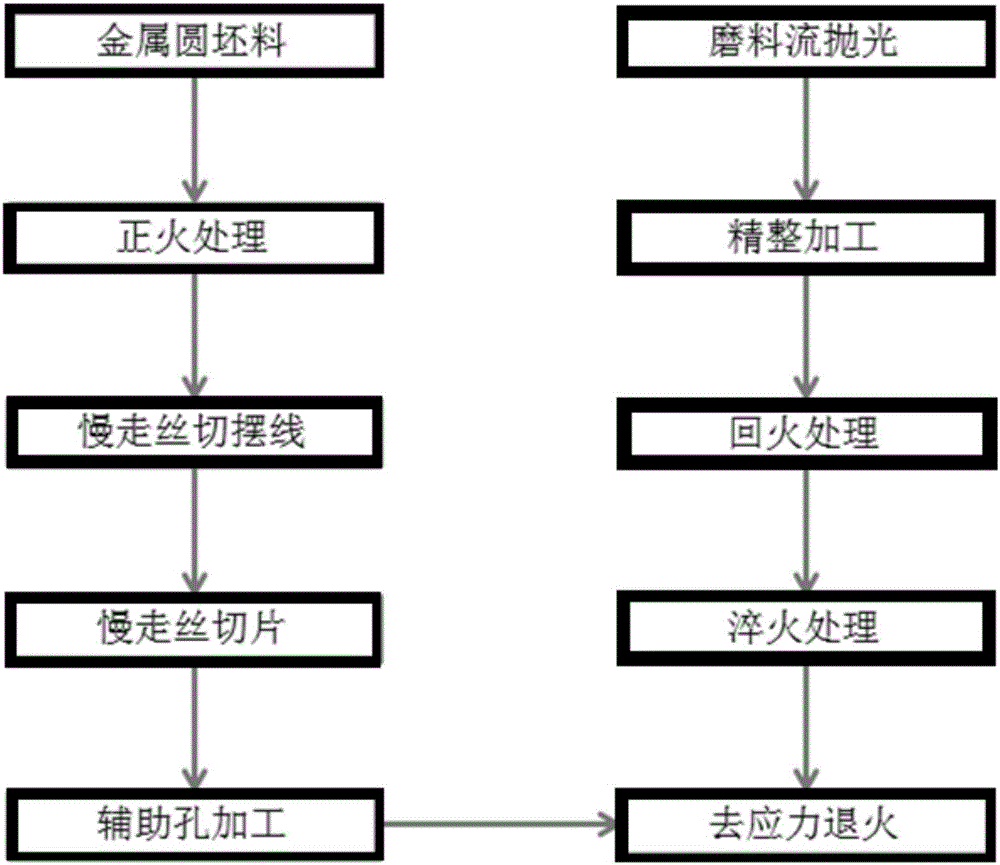

[0026] Such as Figures 1 to 3 shown. The invention discloses a non-traditional processing method for an RV cycloidal gear, comprising the following steps:

[0027] Step 1: Select the metal round blank as the original blank;

[0028] Step 2: Normalize the raw material described in step 1, that is, heat it to 900°C-920°C, keep it warm for 1 hour, then quickly cool it to 580°C-600°C and keep it warm for 1 hour, then take it out of the furnace Cool to room temperature;

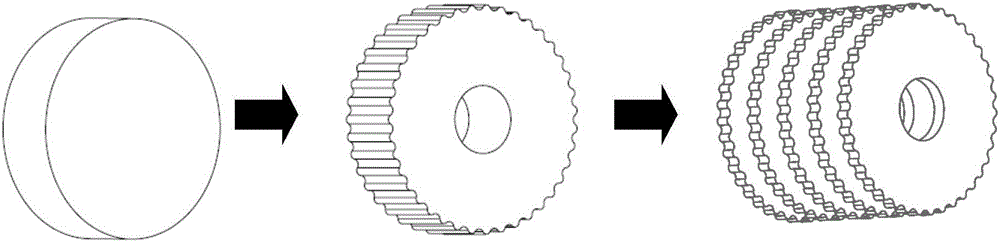

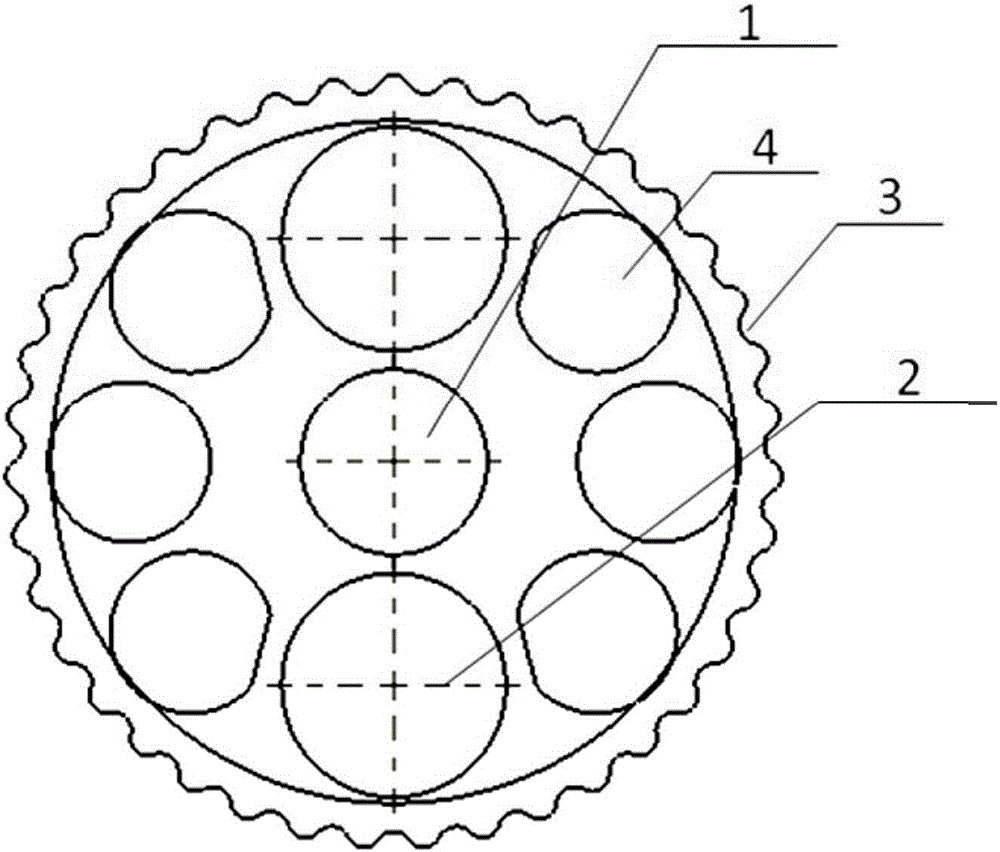

[0029] Step 3: Carry out central circular hole 1 processing to the raw blank after normalizing treatment in step 2, then locate with the central circular hole, carry out slow wire-feeding cutting cycloid 3 to the raw blank, obtain cycloidal gear blank (such as figure 2 shown);

[0030] Step 4: The cycloidal gear blank obtained in Step 3 is subjected to stress-relief annealing treatment at a temperature of 580°C-600°C, after a holding time of 7 hours, and then cooled to 180°C-200°C with the furnace, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com