Arrangements and methods for abrasive flow machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

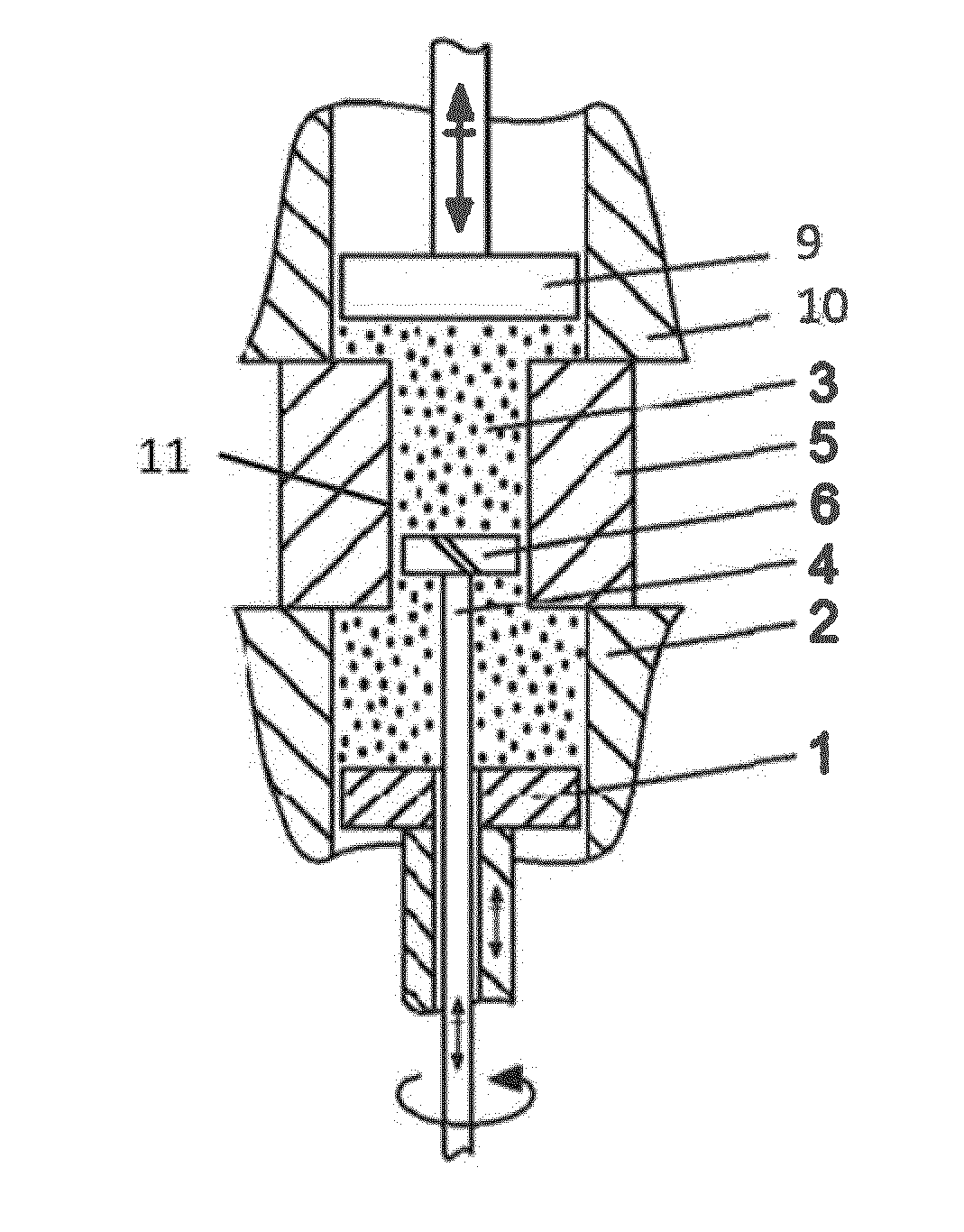

[0063]FIG. 1 shows the invention. Shown is an arrangement for the treatment of an interior surface of a workpiece 5. A cylinder portion 2 and a piston 1 form a first chamber. The first chamber holds and abrasive medium 3. Connected to piston 1 is a rod 4 on which a deflection object 6 is mounted. Deflection object 6, in this embodiment, has spherical shape. Rod 4 keeps deflection object 6 at a fixed distance from piston 1. The first chamber is connected in a fluid-tight manner to workpiece 5. As shown by an arrow on piston 1, the piston is movable downwardly in the vertical direction, so as to impose an increased pressure on abrasive fluid 3 in the first chamber. When piston 1 moves downwardly the first chamber, abrasive fluid 3 is pressed (or extruded) through the internal passage 11 of workpiece 5. In the embodiment shown in FIG. 1, interior passage 11 has an inlet portion at its upper end and an outlet portion at its lower end. The embodiment does not include second chamber conne...

second embodiment

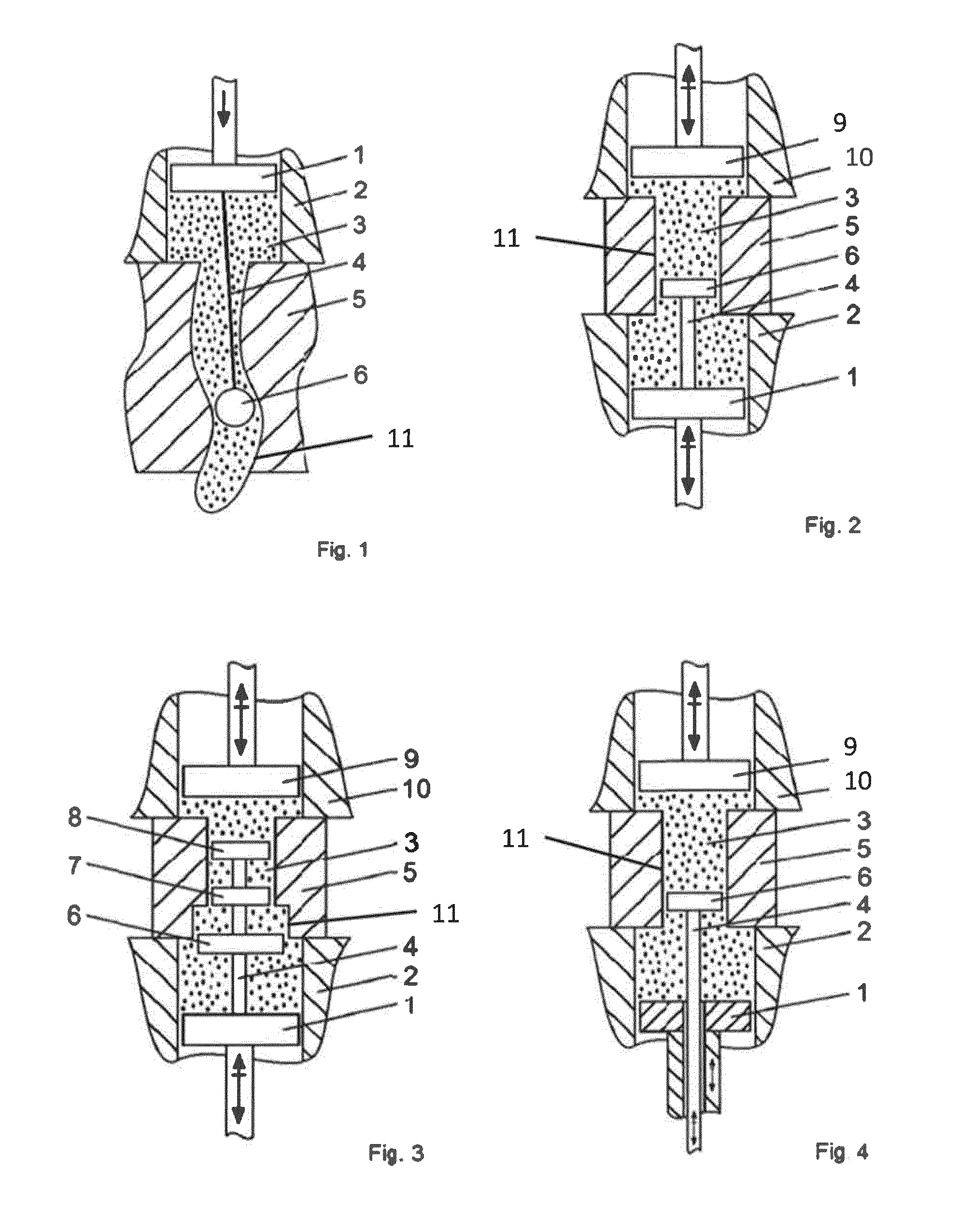

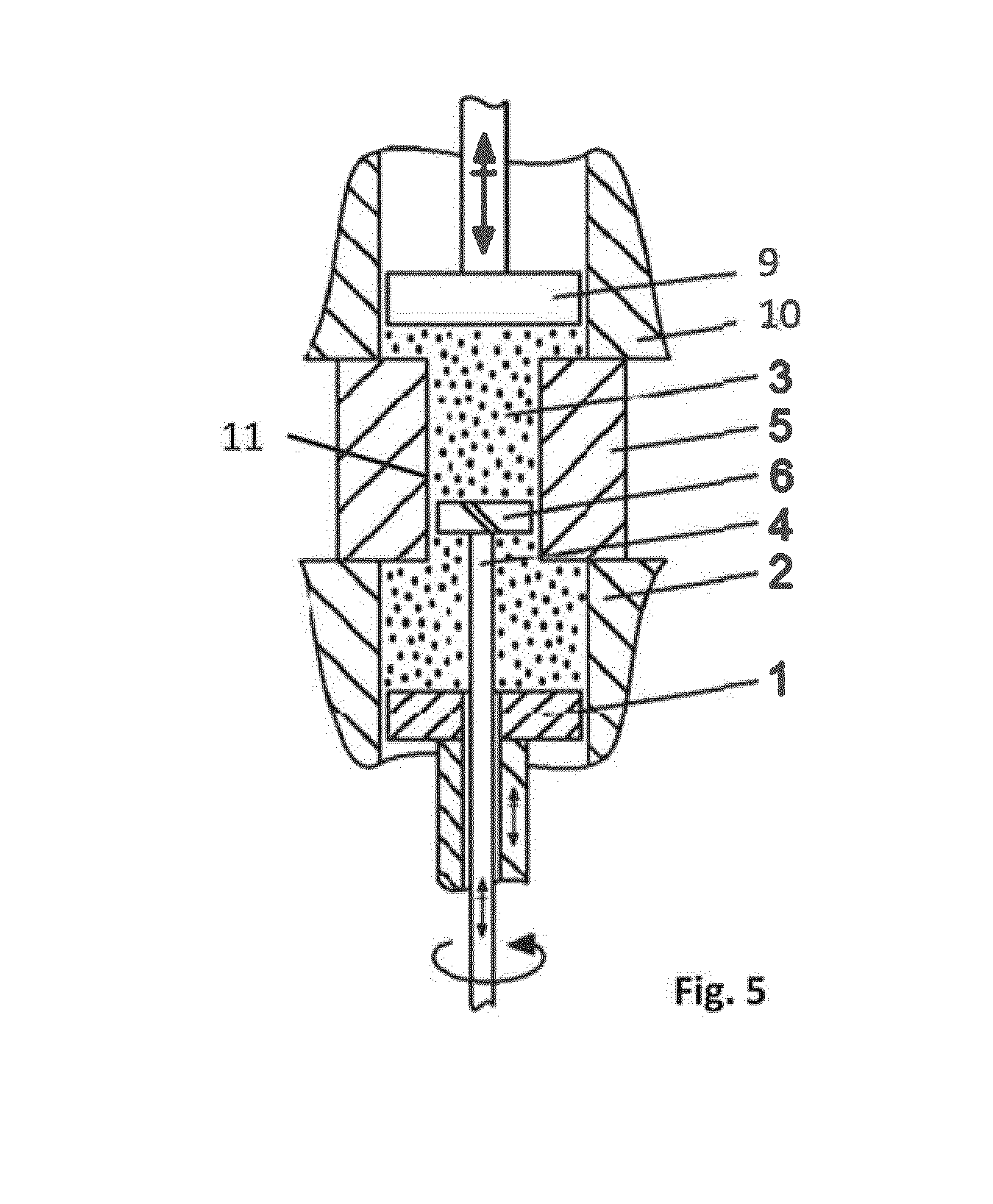

[0064]FIG. 2 depicts the invention. In this embodiment, a first chamber is formed from cylindrical portion 2 and corresponding piston 1. The first chamber is filled with abrasive fluid 3. Piston 1 is movable in a vertical direction, in this case to perform a reciprocating movement. Connected to piston 1 is rod 4 to which deflecting object 6 is connected. Movement of piston 1 effects movement of rod 4 and deflecting object 6 at the same speed and frequency. When piston 1 moves upwardly, abrasive fluid 3 is forced into the interior passage, past the moving deflecting object 6, into a second chamber, in this case formed by second cylindrical portion 10 and second piston 9. As will be readily appreciated by the person skilled in the art, the velocity of abrasive fluid 3 in interior passage 11 is increased around the deflecting object 6, relative to the velocity in the remainder of interior passage 11, because around the deflecting object the available for cross-sectional area for fluid ...

third embodiment

[0065]FIG. 3 shows the invention. This embodiment includes first and second fluid chambers, formed by cylindrical portions 2 and 10 with corresponding pistons 1 and 9, respectively. Reciprocal motion of first and second pistons 1 and 9 effects a reciprocal flow of abrasive medium 3 through the interior passage 11. As can be seen from the Figure, interior passage 11 has sections of different cross-sectional area. A first section, vertically below a second section, has a larger cross-sectional area than has the second section. In conventional abrasive fluid machining arrangements, this would lead to a less effective machining of the surface in the first section having the larger cross-sectional area. According to the invention, however, multiple deflecting objects 6, 7, 8 may be provided in interior passage 11, thereby effecting a substantially uniform treatment of the surfaces of first and second sections. In the embodiment shown in FIG. 3, three separate deflecting objects 6, 7, 8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com