Two-phase fluid abrasive particle sliding speed measuring device and measuring method for viscoelastic fluid abrasive particles

A slip velocity and abrasive particle technology, which is applied in the direction of fluid velocity measurement, measuring device, velocity/acceleration/impact measurement, etc., can solve the problem of difficult measurement of abrasive particle phase slip velocity, and the method of obtaining the angle is simple and easy , mature technology and simple test steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

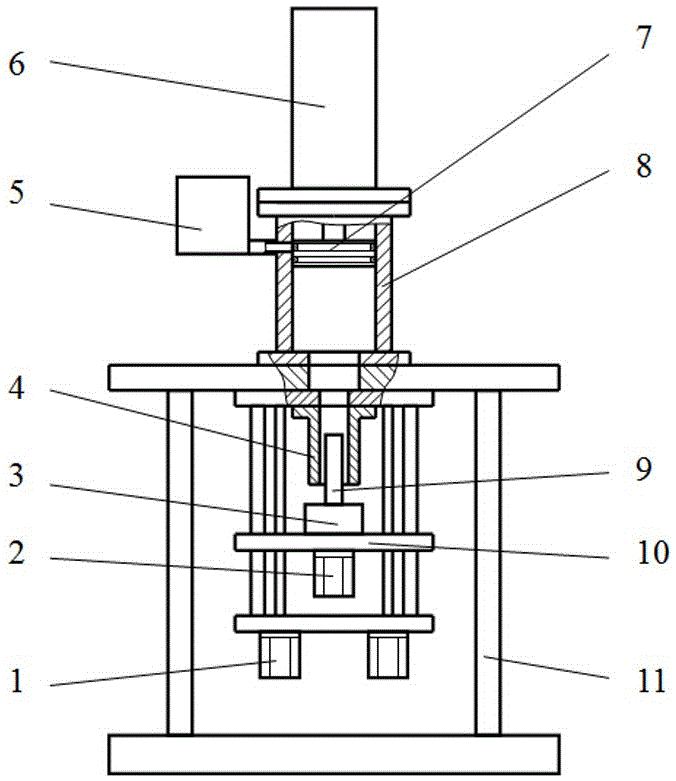

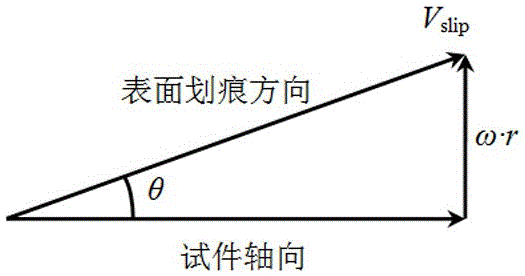

[0023] A device for measuring slip velocity of abrasive particles in viscoelastic fluid abrasive two-phase flow, such as figure 1 As shown, it includes the frame, the pushing cylinder installed on the frame, the pushing piston installed on the pushing cylinder, the feeding cylinder installed on one side of the pushing cylinder, the hydraulic cylinder for powering the pushing piston, the fixed The material extruding tube at the bottom of the pusher cylinder on the frame, the mobile workbench installed on the frame below the material extruding tube, the first motor that pushes the mobile workbench to move up and down, and is installed on the mobile workbench for The chuck for clamping the cylindrical sample, the second motor that drives the chuck to rotate, the inner cavity of the extruded circular tube is connected with the pushing cylinder, and the center line of the cylindrical sample coincides with the rotation axis of the second motor during installation. The centerline of...

Embodiment approach 2

[0037] A viscoelastic fluid abrasive two-phase flow abrasive particle slip velocity measurement device and its measurement method. On the basis of the first embodiment, the lifting motor in the lifting device of the mobile worktable is removed, and the worktable is moved manually. After the sample is moved into the extruded tube of the test system, the rest of the test steps are carried out.

Embodiment approach 3

[0039]A viscoelastic fluid abrasive particle two-phase flow abrasive slip velocity measurement device and its measurement method, on the basis of Embodiment 1, a digital microscope is used to obtain scratch images on the sample surface, image processing is performed, and the wear The particle wall slip velocity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com