Size-variable clamp for abrasive flow machining of valve block through hole

An abrasive flow, variable size technology, applied in the field of variable size fixtures, can solve the problems of poor removal effect and reduce the roughness of through holes inside the valve block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with referring to accompanying drawing, the patent of the present invention is described in detail.

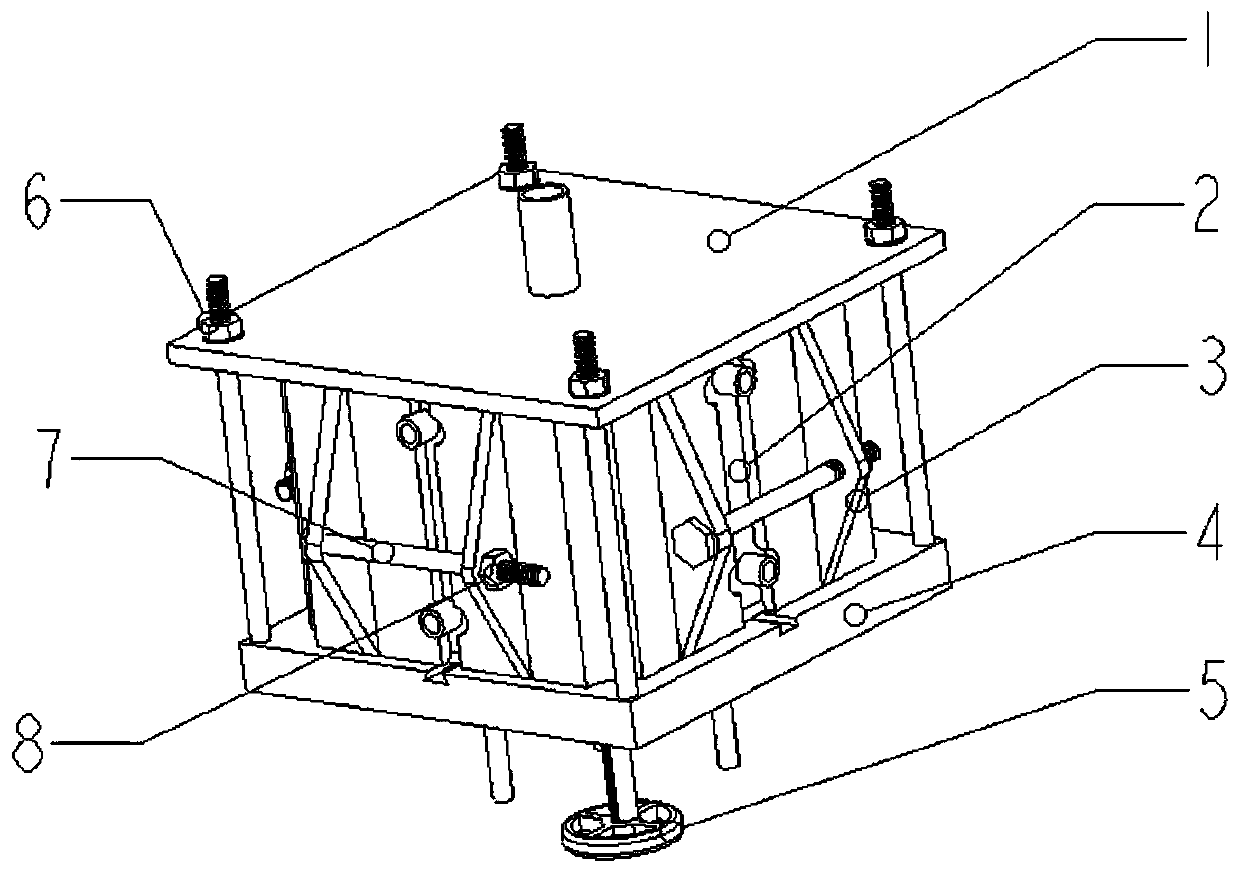

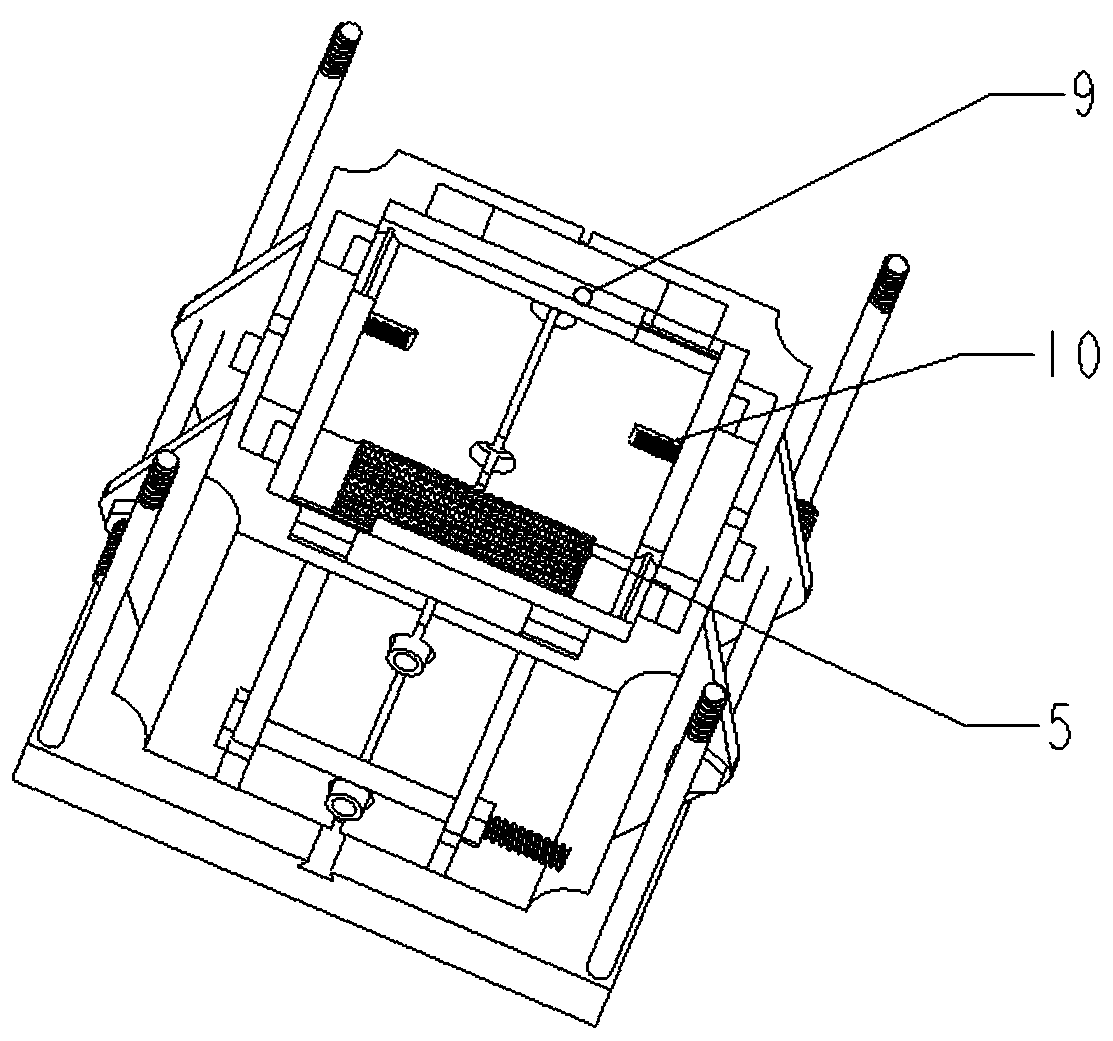

[0027] like figure 1 As shown, a variable size fixture for the through hole of the abrasive flow processing valve block is mainly composed of a cover plate (1), a side plate (2), an angled plate (3), a bottom plate (4), a supporting plate (5), a high direction fastening nuts (6), length and width direction fastening bolts (7) nuts (8), and figure 2 Shown variable washer (9) and partition (10) are formed.

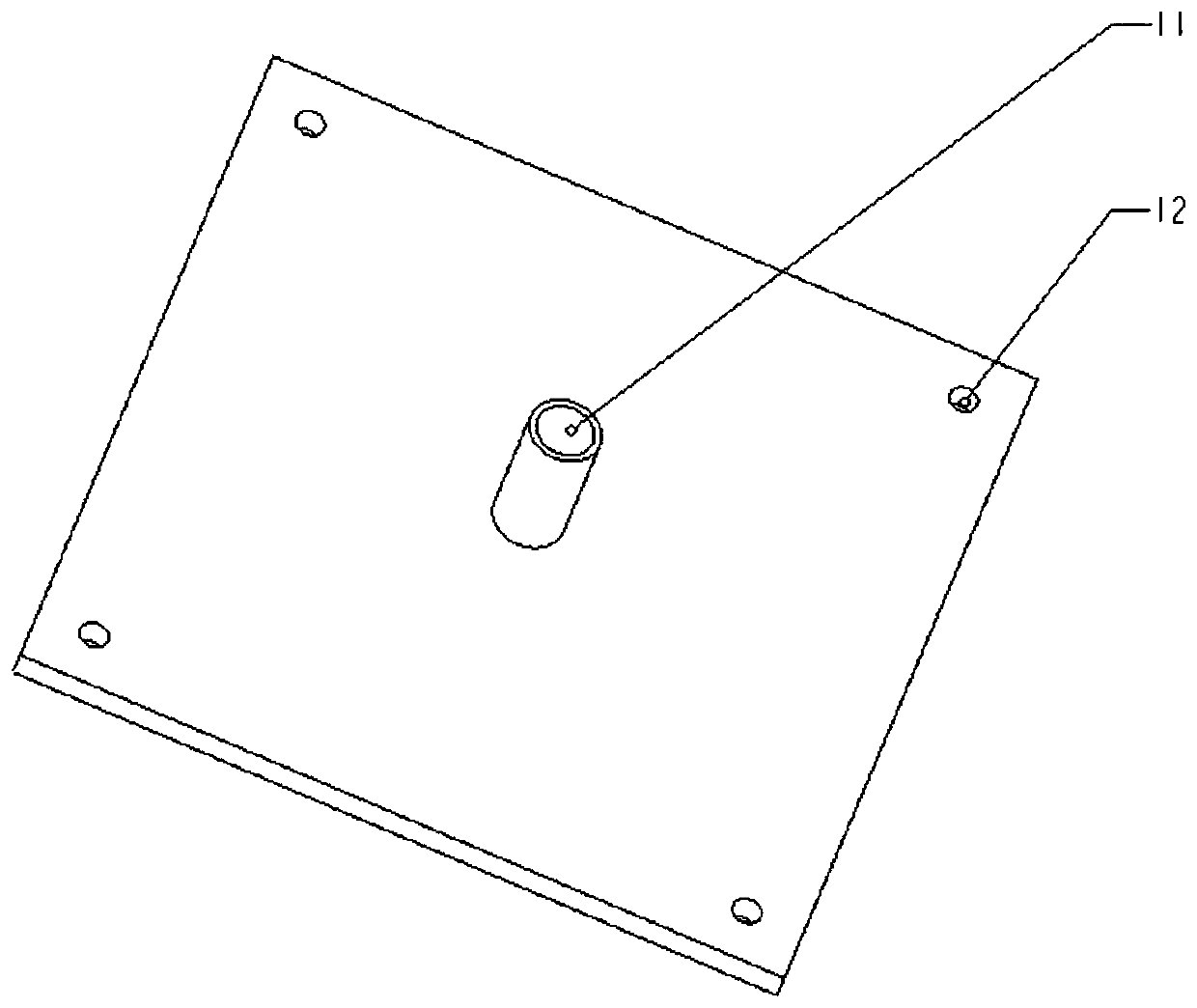

[0028] like image 3 As shown, the cover plate is provided with an abrasive particle flow inlet (11) as the flow path of the abrasive particle flow inlet, and the four corners of the cover plate are respectively provided with through holes, and the four through holes on the base plate are connected with the four through holes on the bottom plate. The two screws cooperate with each other to realize the positioning and clamping of the cover.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com