Oil nozzle abrasive flow machining particle movement numerical simulation method

A technology of numerical simulation and particle movement, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as difficult to meet processing requirements, and achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

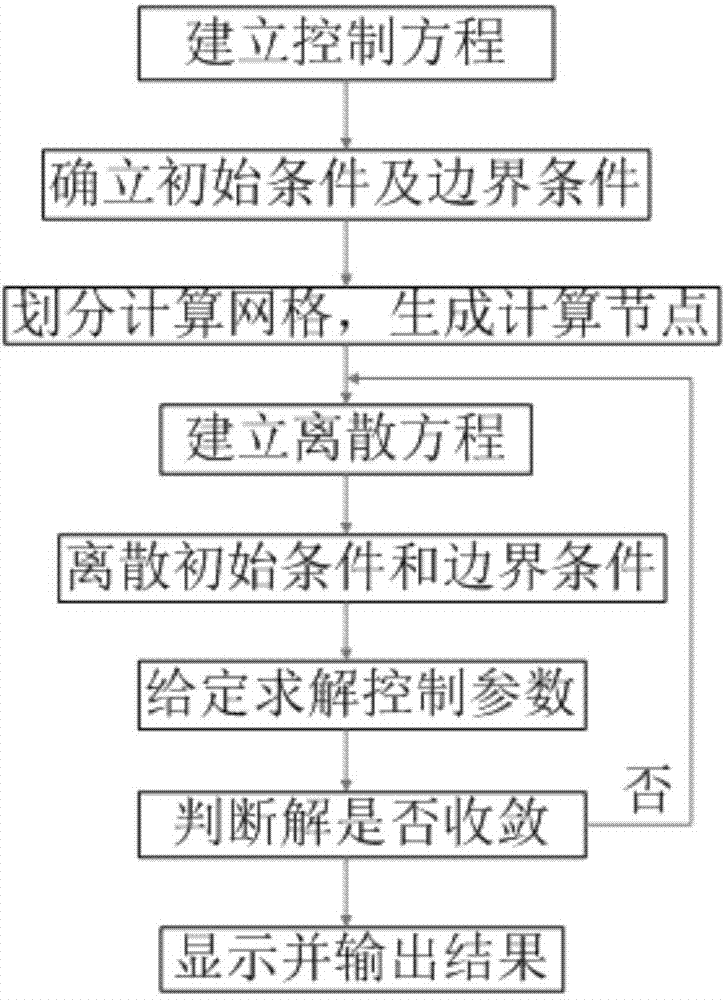

[0023] like figure 1 As shown, the embodiment of the present invention takes the fuel injector as the object, and the specific steps for numerical simulation are as follows:

[0024] (1) Establish a calculation model: the selected fuel injector part is a fuel injector part of a diesel engine, and six small nozzle holes are evenly distributed at its end, the diameter of the large hole in the flow path is 4mm, and the diameter of the small hole is 0.16mm. 3D solid model drawn by Soildworks software. In order to facilitate the simulation analysis, the drawn three-dimensional solid diagram of the fuel injector is simplified, its solid part is hidden, and its internal channel part is abstracted, only the main channel of the fuel injector and the six nozzle channels are reserved.

[0025] (2) Set the solution parameters: Before the simulation, the characteristic parameters, initial parameters, and boundary conditions of the abrasive flow should be set, as follows:

[0026] (2a) In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com