Gel fracturing fluid prepared from oilfield sewage and preparation method thereof

A technology for jelly fracturing fluid and oilfield sewage, applied in the field of fracturing fluid, can solve the problems of inability to meet the needs of on-site construction, abnormal viscosity and cross-linking of fracturing fluid, poor temperature resistance and shear resistance, etc. Liquid viscosity, improve water quality, improve the effect of temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

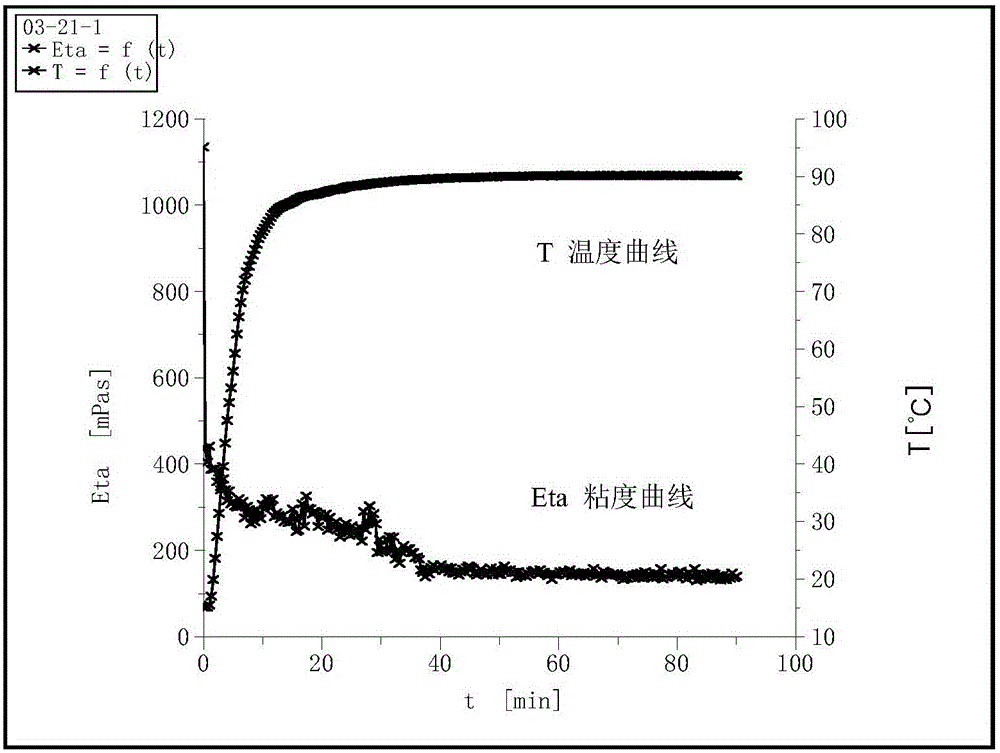

Embodiment 1

[0034] The jelly fracturing fluid that adopts the preparation of oil field sewage of the present embodiment comprises the following components by weight percentage: water quality conditioner 0.03%, isothiazolinone (bactericide) 0.2%, hydroxypropyl guar gum (thickener) 0.35%, organic boron crosslinking agent 0.4%, ammonium persulfate (gel breaker) 0.02%, and the balance is oilfield sewage.

[0035] Wherein, the water quality conditioner is a mixture of fumaric acid and disodium edetate with a mass ratio of 2:1; the organoboron crosslinking agent is purchased from Xinxiang City Xuantai Industrial Co., Ltd.

[0036] The preparation method of the jelly fracturing fluid prepared by using oilfield sewage in this embodiment comprises the following steps:

[0037] 1) Preparation of base liquid: Take oilfield sewage and put it in Wuyin mixer. Under stirring condition, slowly add water quality conditioner (mixture of fumaric acid and disodium edetate), iso Thiazolone and hydroxypropyl ...

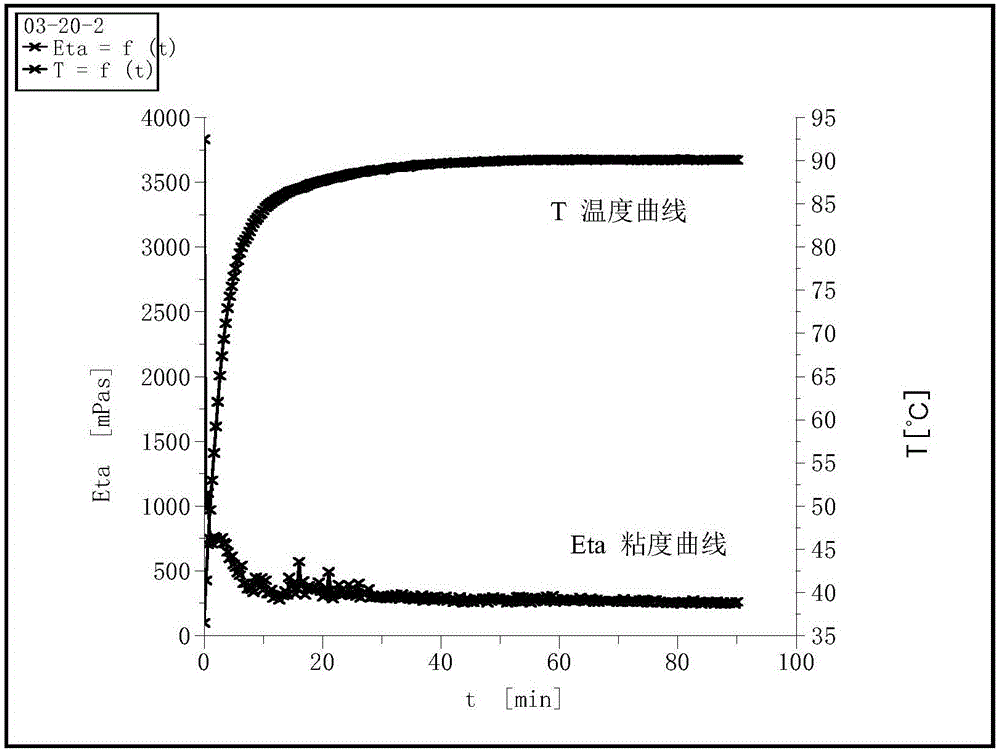

Embodiment 2

[0041] The jelly fracturing fluid that adopts the preparation of oilfield sewage of the present embodiment comprises the following components by weight percentage: water quality conditioner 0.3%, glutaraldehyde (bactericide) 0.2%, hydroxypropyl guar gum (thickener) 0.45% %, organic boron crosslinking agent 0.5%, ammonium persulfate (gel breaker) 0.02%, and the balance is oilfield sewage.

[0042] Wherein, the water quality conditioner is a mixture of hydrochloric acid and disodium edetate with a mass ratio of 1:3; the organoboron crosslinking agent is purchased from Xinxiang City Xuantai Industrial Co., Ltd.

[0043] The preparation method of the jelly fracturing fluid prepared by using oilfield sewage in this embodiment comprises the following steps:

[0044] 1) Preparation of base liquid: take oilfield sewage and put it in Wuyin mixer, under stirring condition, slowly add water quality conditioner (mixture of hydrochloric acid and disodium edetate), glutaraldehyde, hydroxyl ...

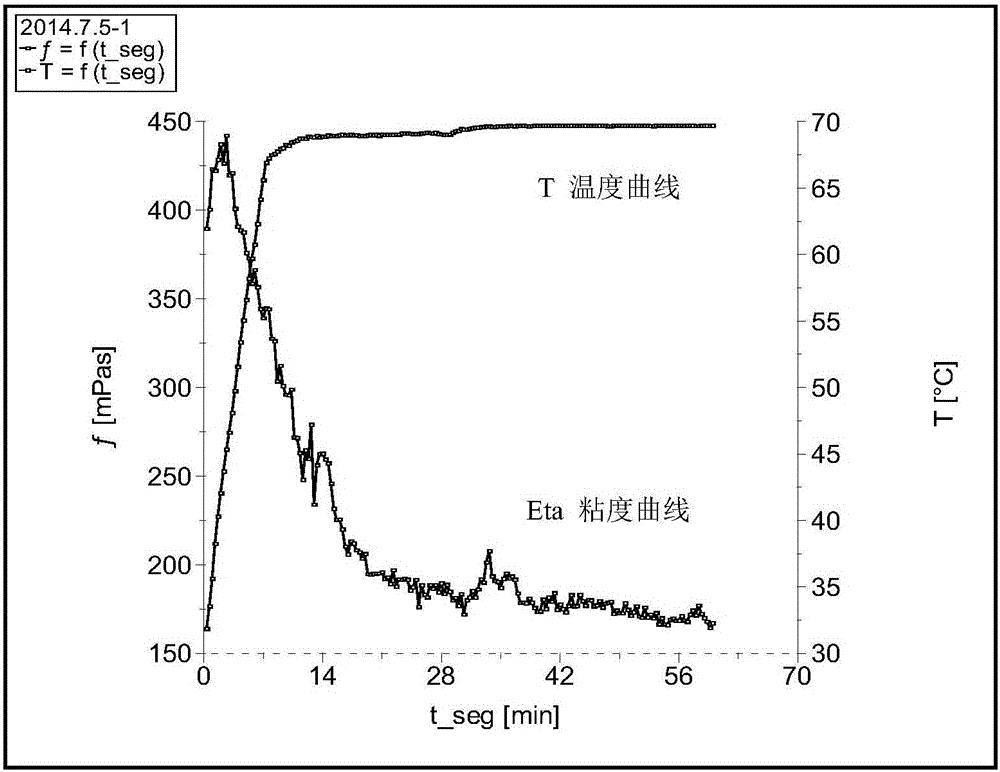

Embodiment 3

[0048] The jelly fracturing fluid that adopts the preparation of oilfield sewage of the present embodiment comprises the following components by weight percentage: water quality conditioner 0.3%, glutaraldehyde (bactericide) 0.2%, carboxymethyl hydroxypropyl guar gum (thickened agent) 0.5%, organoboron crosslinking agent 0.5%, ammonium persulfate (gel breaker) 0.02%, and the balance is oilfield sewage.

[0049] Wherein, the water quality conditioner is a mixture of fumaric acid and disodium ethylenediaminetetraacetic acid in a mass ratio of 1:1; the organoboron crosslinking agent is purchased from Xinxiang City Xuantai Industrial Co., Ltd.

[0050] The preparation method of the jelly fracturing fluid prepared by using oilfield sewage in this embodiment comprises the following steps:

[0051] 1) Preparation of base liquid: take oilfield sewage and put it in Wuyin mixer, under stirring condition, slowly add water quality conditioner (mixture of fumaric acid and disodium ethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com