Method for improving quality of cut tobacco in recovered silver cut stems and treatment system

A processing system and shredded tobacco technology, which is applied in the field of tobacco processing, can solve the problems of unsatisfactory separation effect, reduced air fraction accuracy, and small proportion of stems, so as to improve the air fraction accuracy and effect, avoid over-processing, and ensure blending The effect of matching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

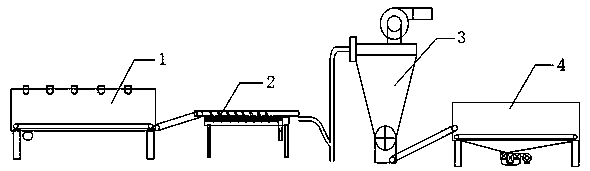

[0031] Send the recovered shredded stems to the room temperature rehydration equipment 1, and use atomized water at a temperature of 15°C to humidify and rehydrate the materials. The shredded tobacco in it will fully absorb the water and stretch, so that the caked shredded tobacco will be peeled off from each other, and the shape of the stems will remain unchanged. . After regaining moisture, the material is placed in the storage cabinet for a period of time to balance its moisture, so that the material can fully absorb moisture to achieve the best effect. Leave it for 20 minutes to achieve the best absorption effect. The water content of the recovered stem shreds is 13%-16% after humidification treatment.

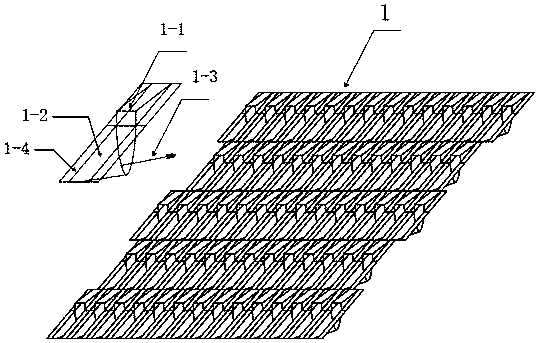

[0032] Send the recycled stalks after moisture regaining to the special-shaped screen 2 for screening and loosening. The surface of the special-shaped screen is provided with a plurality of inclined-plane protrusions 2-1, and the front end of the inclined-plane protrusion...

Embodiment 2

[0036] Send the recovered shredded stems to the room temperature rehydration equipment 1, and use atomized water at a temperature of 22°C to humidify and rehydrate the materials. The shredded tobacco in it will fully absorb the water and stretch, so that the caked shredded tobacco will be peeled off from each other, and the shape of the stems will remain unchanged. . After regaining moisture, the material is placed in the storage cabinet for a period of time to balance its moisture, so that the material can fully absorb moisture to achieve the best effect. Leave it for 40 minutes to achieve the best absorption effect. The water content of the recovered stem shreds is 13%-16% after humidification treatment.

[0037] Send the recycled stalks after moisture regaining to the special-shaped screen 2 for screening and loosening. The surface of the special-shaped screen is provided with a plurality of inclined-plane protrusions 2-1, and the front end of the inclined-plane protrusion...

Embodiment 3

[0041] Send the recovered shredded stems to the room temperature rehydration equipment 1, and use atomized water at a temperature of 40°C to humidify and rehydrate the materials. The shredded tobacco in it will fully absorb the water and stretch, so that the caked shredded tobacco will be peeled off from each other, and the shape of the stems will remain unchanged. . After regaining moisture, the material is placed in the storage cabinet for a period of time to balance its moisture, so that the material can fully absorb moisture to achieve the best effect. Leave it for 60 minutes to achieve the best absorption effect. The water content of the recovered stem shreds is 13%-16% after humidification treatment.

[0042] Send the recycled stalks after moisture regaining to the special-shaped screen 2 for screening and loosening. The surface of the special-shaped screen is provided with a plurality of inclined-plane protrusions 2-1, and the front end of the inclined-plane protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com