Bacillus subtilis ansb0e1 and its application

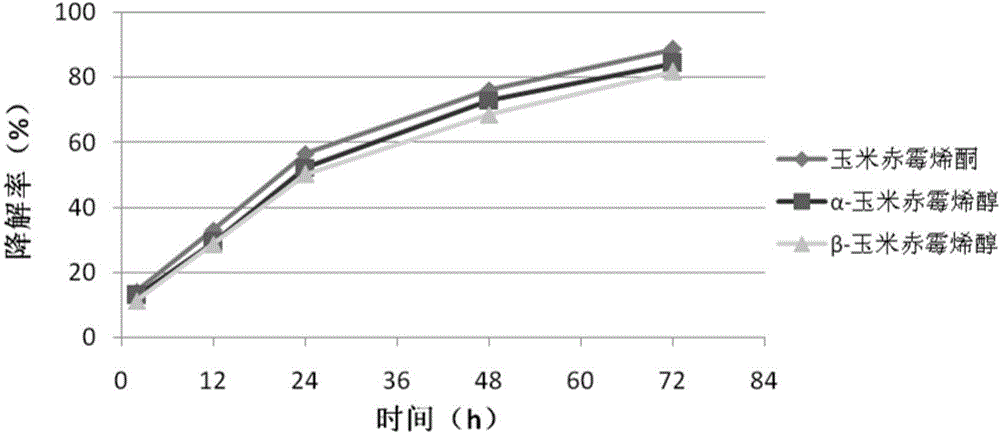

A technology of ANSB0E1 and Bacillus subtilis, which is applied in the field of microbiology, can solve the problems of less zearalenone and no simultaneous degradation of zearalenone by Bacillus subtilis. 1. Moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The cultivation method of embodiment 1 bacillus subtilis ANSBOE1

[0036] Take 1 mL of Bacillus subtilis ANSB0E1 (CGMCC No.8515) (the concentration of live bacteria is 10 9 CFU / mL), inoculated in 50mL medium for shake flask fermentation, the fermentation temperature was 37°C, the pH value was 7.2, the rotation speed was 200r / min, and the fermentation time was 24h.

[0037] Among them, the shake flask fermentation medium is composed of the following components: tryptone 10g, yeast extract 1.5g, glucose 5g, beef extract 3g, sodium chloride 6g, disodium hydrogen phosphate 2.5g, magnesium sulfate heptahydrate 1g and distilled water 1000mL, pH 7.0.

[0038] After the fermentation, the fermentation broth was stored in a refrigerator at 4°C for later use.

Embodiment 2

[0039] The cultivation method of embodiment 2 Bacillus subtilis ANSBOE1

[0040]Take 1 mL of Bacillus subtilis ANSB0E1 (CGMCC No.8515) (the concentration of live bacteria is 10 9 CFU / mL), inoculated in 80mL medium for shake flask fermentation, the fermentation temperature was 25°C, the pH value was 7.5, the rotation speed was 225r / min, and the fermentation time was 28h.

[0041] Among them, the shake flask fermentation medium is composed of the following components: tryptone 12g, yeast extract 2g, glucose 4g, beef extract 2g, sodium chloride 5g, disodium hydrogen phosphate 3g, magnesium sulfate heptahydrate 0.5g and distilled water 800mL , pH value is 7.2.

[0042] After the fermentation, the fermentation broth was stored in a refrigerator at 4°C for later use.

Embodiment 3

[0043] The cultivation method of embodiment 3 Bacillus subtilis ANSBOE1

[0044] Take 1 mL of Bacillus subtilis ANSB0E1 (CGMCC No.8515) (the concentration of live bacteria is 10 9 CFU / mL), inoculated in 100mL medium for shake flask fermentation, the fermentation temperature was 45°C, the pH value was 6.8, the rotational speed was 185r / min, and the fermentation time was 18h.

[0045] Among them, the shake flask fermentation medium is composed of the following components: tryptone 7g, yeast extract 2.5g, glucose 3g, beef extract 4g, sodium chloride 4g, disodium hydrogen phosphate 3.5g, magnesium sulfate heptahydrate 1.25g and Distilled water 1200mL, pH value is 7.4.

[0046] After the fermentation, the fermentation broth was stored in a refrigerator at 4°C for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com