A kind of preparation method and application of modified shredded tobacco stem

A shredded tobacco stem and modification technology, which is applied in the fields of application, tobacco, and tobacco treatment, can solve the problem of reduced sensory quality of shredded tobacco, and achieve the effects of no reduction in sensory quality, simple preparation process, and unaffected sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

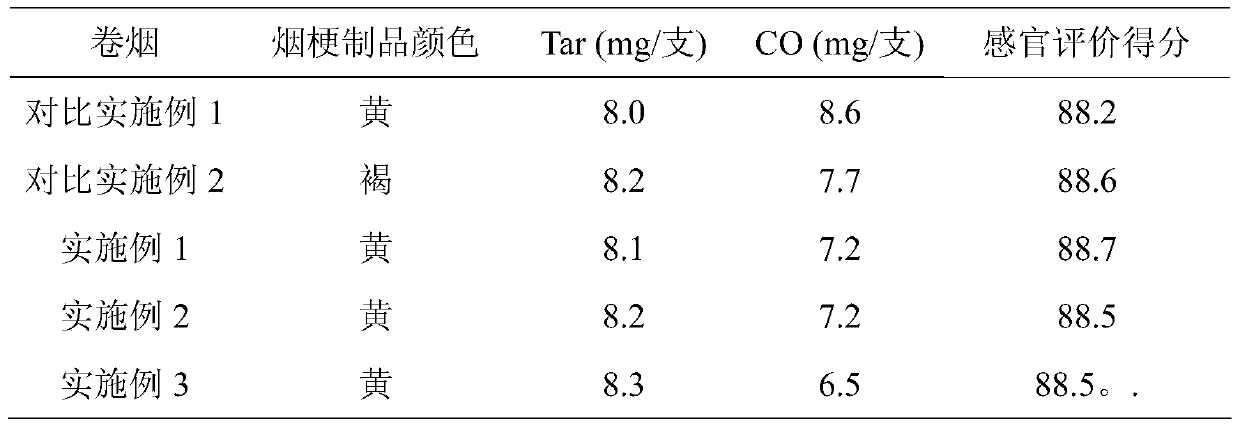

Embodiment 1

[0031]Add 10 kg of hot water at 60°C to a certain container, then add 0.4 kg of L-cysteine, and stir until it is completely dissolved; add 2 kg of tobacco stems into the container, dip it so that the water content reaches 33.2%, and then place it for 2 hours; use a conventional stem cutter to cut the tobacco stems, the thickness of the cut stems is 0.5 mm; shred the stem slices with a shredder, and the shred width is 1.1 mm; dry the modified cut stems obtained, and observe the modified cut stems color, and then place the modified shredded stem in an environment with a temperature of (22±1)° C. and a relative humidity of (60±3)% for 48 hours and set aside. The modified shredded stem prepared by the above method is added into the shredded tobacco according to the proportion of 10%, and then cigarettes are rolled according to the conventional production method. The tar release amount and carbon monoxide release amount of cigarettes were measured, and the sensory quality was evalu...

Embodiment 2

[0033] Add 10 kg of hot water at 70°C to a certain container, then add 0.3 kg of L-cysteine, and stir until it is completely dissolved; add 2 kg of tobacco stems into the container, dip it so that the water content reaches 34.7%, and then place it for 3 hours; cut the tobacco stems with a conventional stem cutter, and the thickness of the cut stems is 0.7 mm; shred the stem slices with a shredder, and the shredded width is 1.2 mm; dry the modified cut stems obtained, and observe the modified cut stems color, and then place the modified shredded stem in an environment with a temperature of (22±1)° C. and a relative humidity of (60±3)% for 48 hours and set aside. The modified shredded stem prepared by the above method is added into the shredded tobacco according to the proportion of 10%, and then cigarettes are rolled according to the conventional production method. The tar release amount and carbon monoxide release amount of cigarettes were measured, and the sensory quality was...

Embodiment 3

[0035] Add 10 kg of hot water at 70°C to a certain container, then add 0.5 kg of L-cysteine, and stir until it is completely dissolved; add 2 kg of tobacco stems into the container, soak it so that its water content reaches 32.7%, and then place it for 4 hours; cut the tobacco stems with a conventional stem cutter, and the thickness of the cut stems is 0.8 mm; shred the stem slices with a shredder, and the shred width is 1.0 mm; dry the modified cut stems obtained, and observe the modified cut stems color, and then place the modified shredded stem in an environment with a temperature of (22±1)° C. and a relative humidity of (60±3)% for 48 hours and set aside. The modified shredded stem prepared by the above method is added into the shredded tobacco at a ratio of 20%, and then cigarettes are rolled according to the conventional production method. The tar release amount and carbon monoxide release amount of cigarettes were measured, and the sensory quality was evaluated. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com