Method for improving thin-film semiconductor transistor electrical property

A thin-film semiconductor and electrical performance technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of difficult industrial production, sacrificing device performance, electrical performance deterioration, etc., to achieve uniform thickness, high purity, Good coating or film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

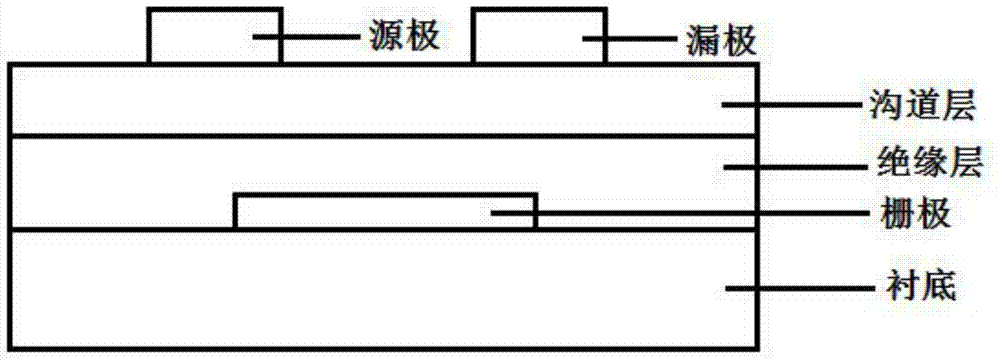

[0065] A method for improving the electrical performance of a thin film semiconductor transistor, specifically, covering the surface of the thin film semiconductor transistor with an organic layer.

[0066] The advantage of the design here is that an organic layer is covered on the surface of the thin film semiconductor transistor, on the one hand, the thin film semiconductor transistor is largely isolated from the outside air, and the H in the air is greatly reduced. 2 O, O 2 and (OH) - and other substances have a negative impact on the performance of thin film semiconductor transistors; on the other hand, it greatly reduces the defect states on the surface of thin film semiconductor transistors, because the surface defect states will bind the transport of carriers in the device, resulting in deterioration of the performance of thin film semiconductor transistors, Therefore, after covering an organic layer, the performance of the thin film semiconductor transistor is greatly...

Embodiment 2

[0069] According to the method for improving the electrical performance of the thin film semiconductor transistor described in Embodiment 1, the difference is that the organic layer is polyimide.

Embodiment 3

[0071] According to the method for improving the electrical performance of the thin film semiconductor transistor described in Embodiment 1, the difference is that the organic layer is a photoresist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com