Preparation method of absorption layer of thin film solar cell

A technology of solar cells and thin film layers, applied in the field of solar cells, can solve the problems of high process temperature, high production cost, affecting production efficiency, etc., and achieve the effect of improving the average deposition rate and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

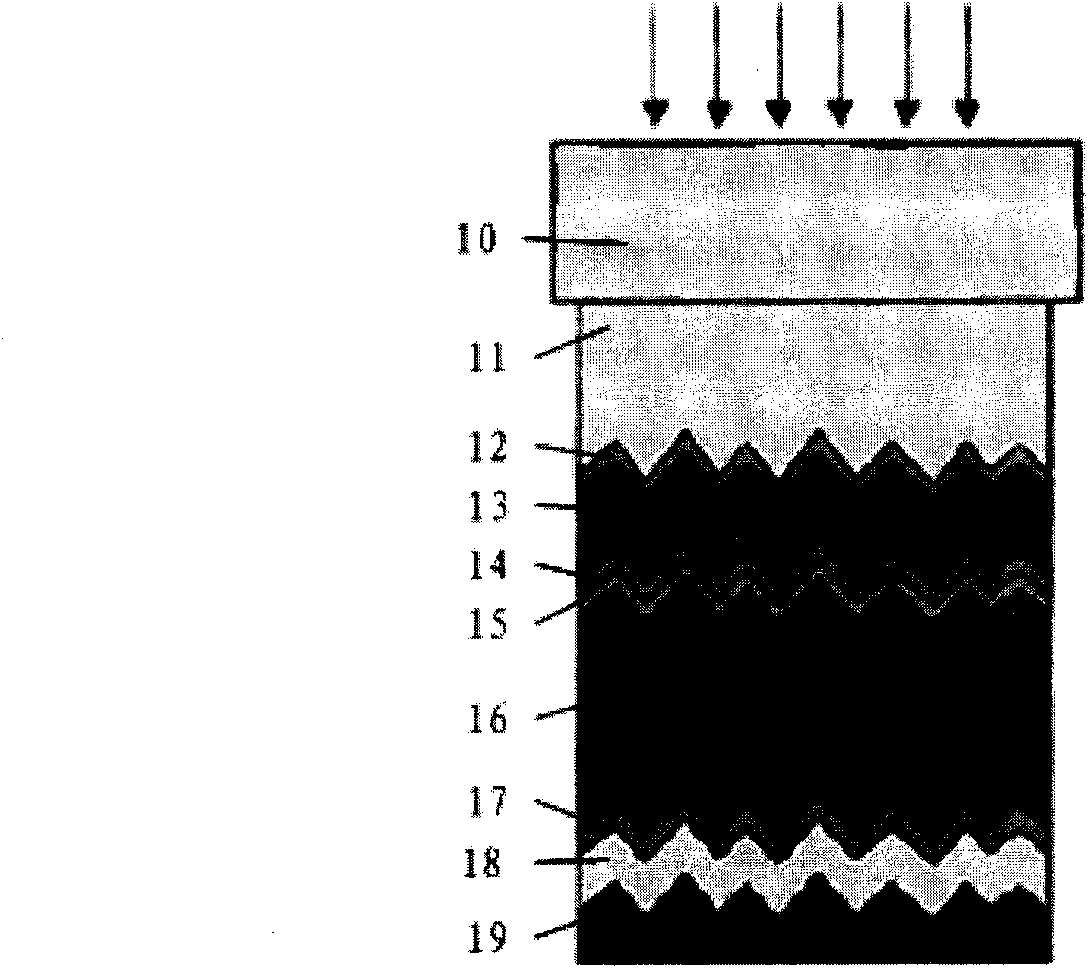

[0038] image 3 It is a flow chart of the preparation method of the absorbing layer of the thin film solar cell in this embodiment. Figure 4 to Figure 5 It is a schematic diagram of the preparation method of the absorbing layer of the thin-film solar cell in this embodiment.

[0039] Such as image 3 with Figure 4 As shown, step S1: providing a substrate 100 having a p-type silicon-based thin film layer 102 .

[0040] The substrate 100 can be a transparent conductive glass (ZnO-TCOGlass) with a ZnO texture film layer, and has an amorphous silicon (a-Si:H) absorption layer 101 on the substrate 100, and the amorphous silicon absorbs Layer 101 includes a p-i-n structure, that is, p-type amorphous silicon layer / intrinsic amorphous silicon layer / n-type amorphous silicon layer. The amorphous silicon absorption layer 101 is used in thin-film solar cells to absorb short-wave sunlight to generate photovoltaic effects. The amorphous silicon absorption layer 101 also has a p-type sil...

Embodiment 2

[0051] Image 6 It is a flow chart of the preparation method of the absorbing layer of the thin film solar cell in this embodiment.

[0052] Such as Image 6 As shown, step P1: providing a substrate with a p-type silicon-based thin film layer on the substrate;

[0053] Step P2: alternately performing hydrogenation treatment and depositing an intrinsic silicon-based thin film layer on the p-type silicon-based thin film layer. During this process, the deposition rate of the intrinsic silicon-based thin film layer gradually increases.

[0054] Specifically, the surface of the substrate with the p-type silicon-based thin film layer is hydrogenated for 3-30s, and then the intrinsic silicon-based thin film layer is deposited at the first deposition rate V1, and the deposition time is 10-100s , followed by hydrogenation treatment for 3-60s, and then depositing the intrinsic silicon-based thin film layer at the second deposition rate V2 for 10-100s, the second deposition rate being ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com