Crystal silicon and silicon germanide film compound unijunction PIN solar battery with transition layer, and preparation method thereof

A solar cell and transition layer technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that no one has developed a thin-film solar cell manufacturing technology, and no one has developed a single-junction PIN solar cell manufacturing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

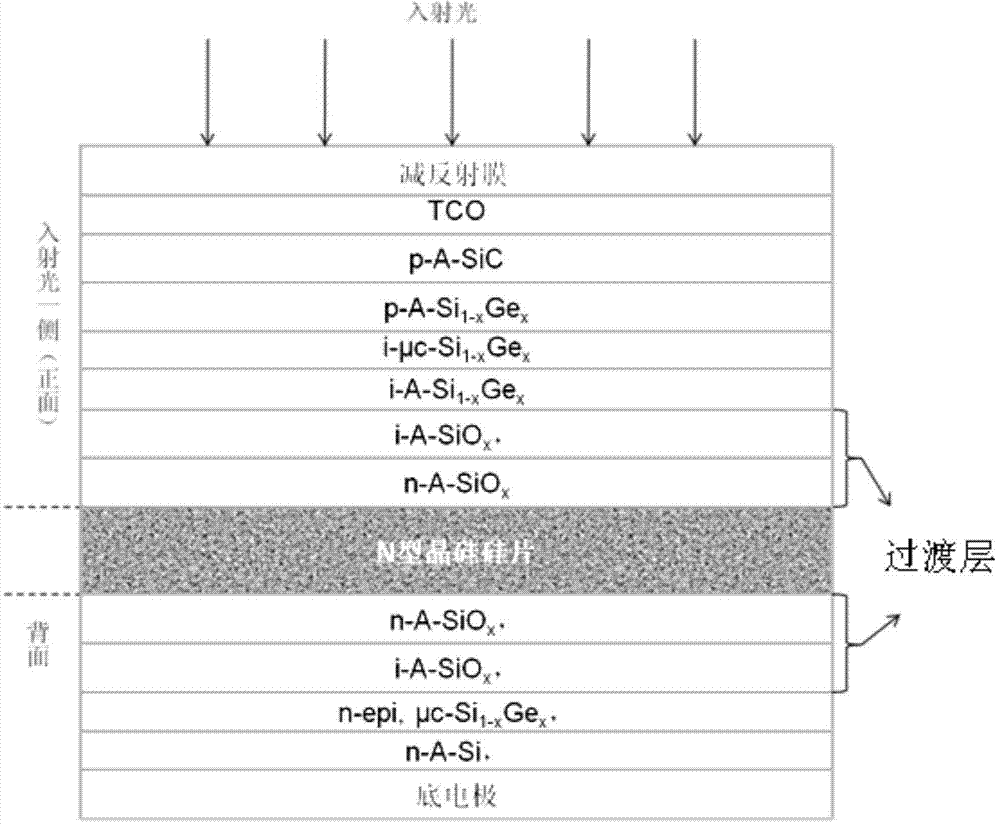

[0081] Crystalline silicon and silicon germanium thin film composite single-junction PIN solar cells with a transition layer structure, selected from one of the following solar cell structures:

[0082] 10) Bottom electrode / n layer / n-type silicon wafer / transition layer / i-A-Si 1-x Ge x layer / p-A-Si 1-x Ge x layer / TCO / anti-reflection coating;

[0083] 11) Bottom electrode / n layer / n-type silicon wafer / transition layer / i-μc-Si 1-x Ge x layer / i-A-Si 1-x Ge x layer / p-A-Si 1-x Ge x layer / TCO / anti-reflection coating;

[0084] 12) Bottom electrode / n layer / n-type silicon wafer / transition layer / p-A-Si 1-x Ge x layer / TCO / anti-reflection coating;

[0085] 13) Bottom electrode / n layer / transition layer / n-type silicon wafer / i-A-Si 1-x Ge x layer / p-A-Si 1-x Ge x layer / TCO / anti-reflection coating;

[0086] 14) Bottom electrode / n layer / transition layer / n-type silicon wafer / i-μc-Si 1-x Ge x layer / i-A-Si 1-x Ge x layer / p-A-Si 1-xGe x layer / TCO / anti-reflection coating;

[00...

Embodiment 2

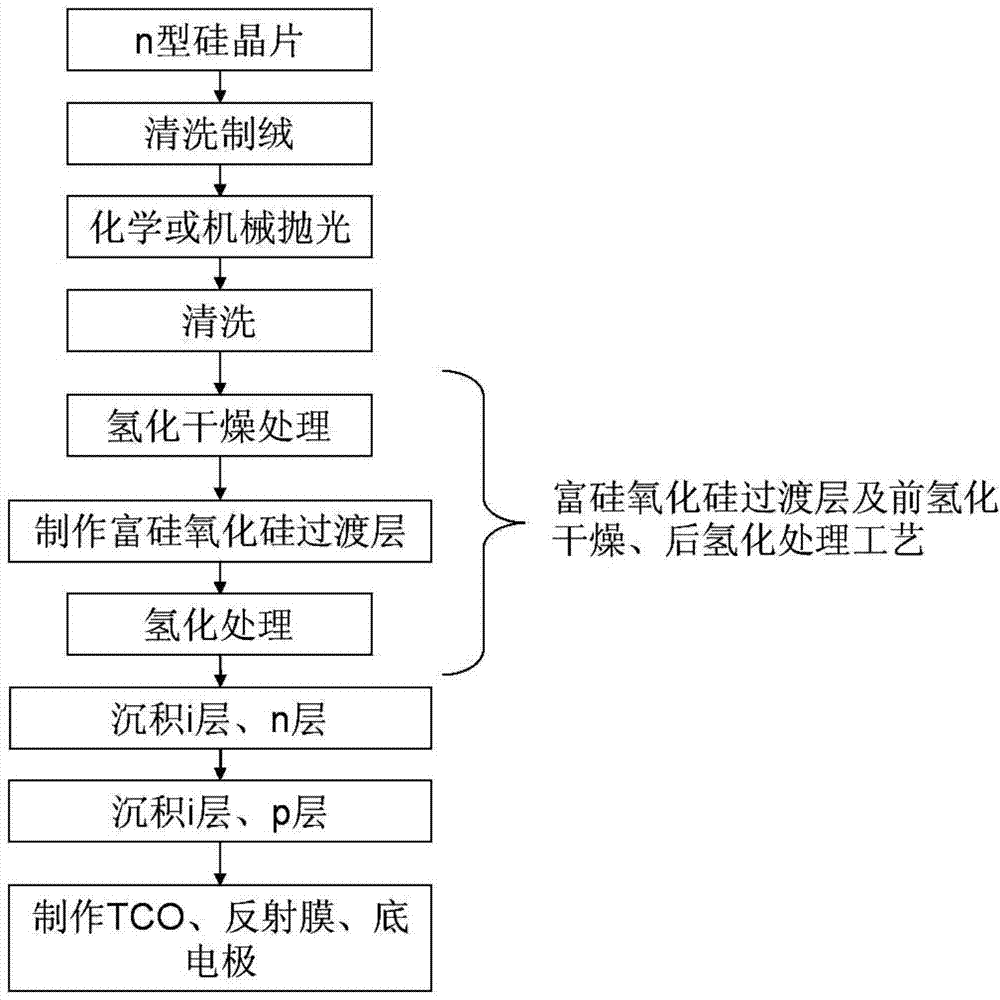

[0097] The manufacturing method of the transition layer, such as figure 2 shown, including the following methods:

[0098] The first type: After preliminary cleaning, chemical texturing, chemical or mechanical double-sided polishing of the n-type silicon wafer, the n-type silicon wafer is cleaned again, and the cleaned silicon wafer is pre-hydrogenated and dried. The treatment method is as follows: : Send the silicon wafer to the equipment with a closed chamber, evacuate the atmosphere until the chamber pressure is less than or equal to (≤) 1Pascal; the chamber temperature is controlled between 30°C and 350°C, and hydrogen or a mixture of hydrogen and nitrogen is introduced gas; dry silicon wafers under a hydrogen atmosphere. The purity of hydrogen and nitrogen is greater than or equal to (≥) 99.99%; if a mixed gas is used, the volume ratio of hydrogen and nitrogen is 0.1 to 100 times; the hydrogenation drying time is 1 to 60 minutes. Send the hydrogenated and dried silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com