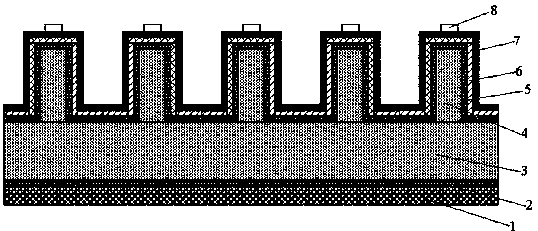

Solar cell and preparation method thereof

A technology for solar cells and substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the photoelectric conversion efficiency of organic-inorganic solar cells, being unable to be applied on a large scale, and taking a long time for methylation treatment. Improve the photoelectric conversion efficiency, increase the contact increase, and the effect of the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a solar cell proposed in a specific embodiment of the present invention comprises the following steps:

[0018] (1) Cleaning of n-type silicon substrates: cut n-type silicon wafers into n-type silicon substrates with a size of 3 cm×3 cm, and then ultrasonically clean the n-type silicon substrates in acetone, ethanol, and deionized water for 10 -15 minutes, then put in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 100-110°C for 50-70 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, and then rinse the n-type silicon substrate with deionized water, and dry it with nitrogen for standby;

[0019] (2) Prepare a silicon nanowire array on the upper surface of the n-type silicon substrate: place the n-type silicon substrate obtained in step 1 in a mixed solution of silver nitrate / hydrofluoric acid, wherein the silver nitrate / hydrofluoric acid The molar concentration o...

Embodiment 1

[0026] A method for preparing a solar cell, comprising the steps of:

[0027] (1) Cleaning of n-type silicon substrates: cut n-type silicon wafers into n-type silicon substrates with a size of 3 cm×3 cm, and then ultrasonically clean the n-type silicon substrates in acetone, ethanol, and deionized water for 12 minutes, then put in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 105°C for 70 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, and then rinse the n-type silicon substrate with deionized water, and dry it with nitrogen for standby;

[0028] (2) Prepare a silicon nanowire array on the upper surface of the n-type silicon substrate: place the n-type silicon substrate obtained in step 1 in a mixed solution of silver nitrate / hydrofluoric acid, wherein the silver nitrate / hydrofluoric acid The molar concentration of hydrofluoric acid in the acid mixed solution is 4.8mol / l, and the molar c...

Embodiment 2

[0035] A method for preparing a solar cell, comprising the steps of:

[0036] (1) Cleaning of n-type silicon substrates: cut n-type silicon wafers into n-type silicon substrates with a size of 3 cm×3 cm, and then ultrasonically clean the n-type silicon substrates in acetone, ethanol, and deionized water for 15 minutes, then put in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 110°C for 50 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, and then rinse the n-type silicon substrate with deionized water, and dry it with nitrogen for standby;

[0037] (2) Prepare a silicon nanowire array on the upper surface of the n-type silicon substrate: place the n-type silicon substrate obtained in step 1 in a mixed solution of silver nitrate / hydrofluoric acid, wherein the silver nitrate / hydrofluoric acid The molar concentration of hydrofluoric acid in the acid mixed solution is 4.8mol / l, and the molar c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com