Crystalline silicon and silicon film composite type unijunction PIN solar cell with transition layers and preparation method for crystalline silicon and silicon film composite type unijunction PIN solar cell

A solar cell and transition layer technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that no one has developed a single-junction PIN solar cell manufacturing method, and no one has developed a thin-film solar cell manufacturing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

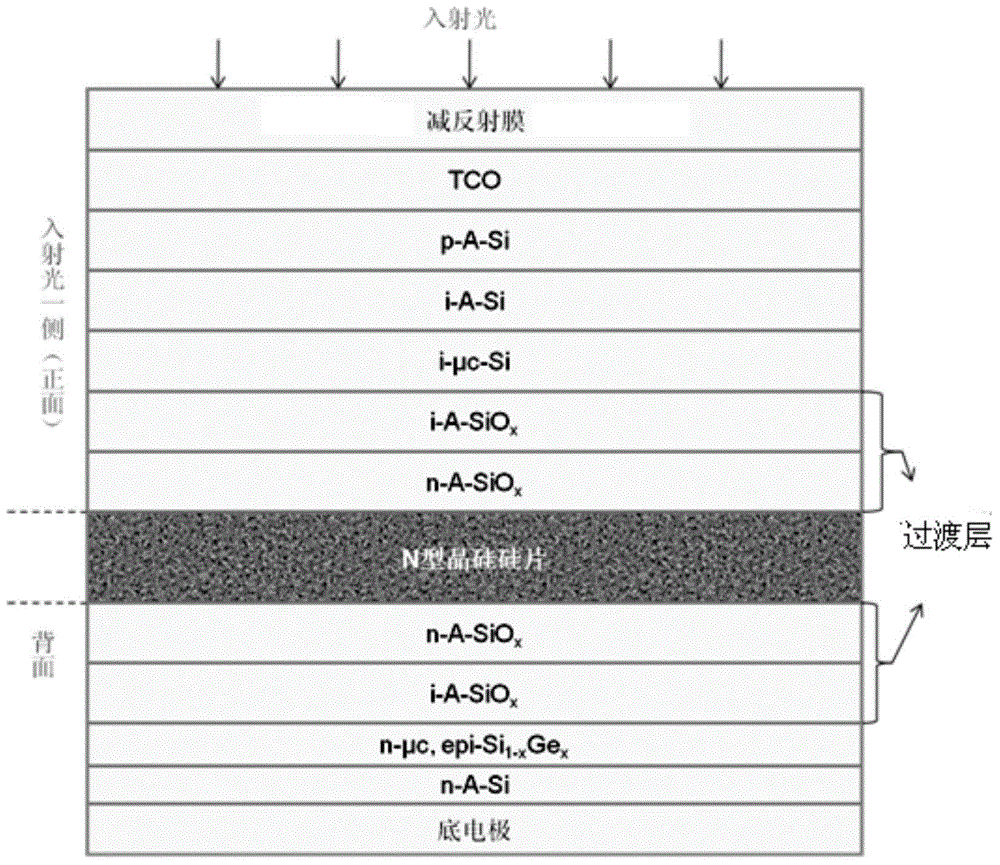

[0077] A kind of crystalline silicon and silicon thin film composite type single-junction PIN solar cell with transition layer, comprises n-type silicon wafer, is characterized in that, on the front surface of n-type silicon wafer or on the back surface of n-type silicon wafer or on n-type silicon wafer The front surface and the back surface of the silicon wafer are provided with a transition layer; the transition layer is one or more layers, any one of which is a silicon-rich silicon oxide layer; the silicon-rich silicon oxide layer is selected from i-A-SiO x , i-μc-SiO x , n-A-SiO x , n-μc-SiO x Any of the above, wherein 0≤x≤2; or the silicon-rich silicon oxide layer is selected from n-type gradient μc-SiO x and n-type gradient A-SiO x , where 0≤x≤2, the "gradient" means: by changing the value of x in the silicon-rich silicon oxide gradually changes from 2 to 0, while the silicon oxide changes from silicon oxide——to silicon-rich silicon oxide layer— — then change to the ...

Embodiment 2

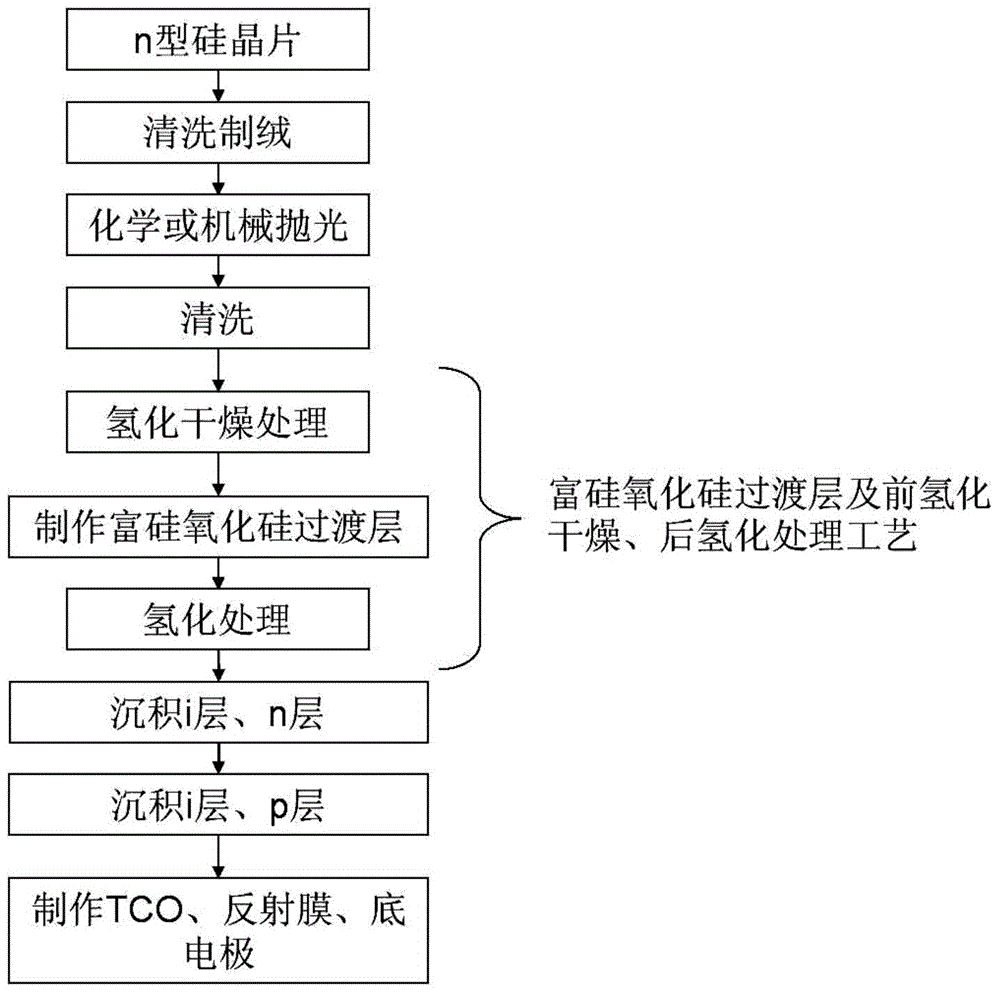

[0080] The manufacturing method of the transition layer, such as figure 2 shown, including the following methods:

[0081] The first type: After preliminary cleaning, chemical texturing, chemical or mechanical double-sided polishing of the n-type silicon wafer, the n-type silicon wafer is cleaned again, and the cleaned silicon wafer is pre-hydrogenated and dried. The treatment method is as follows: : Send the silicon wafer to the equipment with a closed chamber, evacuate the atmosphere until the chamber pressure is less than or equal to (≤) 1Pascal; the chamber temperature is controlled between 30°C and 350°C, and hydrogen or a mixture of hydrogen and nitrogen is introduced gas; dry silicon wafers under a hydrogen atmosphere. The purity of hydrogen and nitrogen is greater than or equal to (≥) 99.99%; if a mixed gas is used, the volume ratio of hydrogen and nitrogen is 0.1 to 100 times; the hydrogenation drying time is 1 to 60 minutes. Send the hydrogenated and dried silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com