High-efficiency passivated contact crystalline silicon solar cell and preparation method thereof

A solar cell, crystalline silicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the bulk resistivity filling factor of silicon wafers, high bulk resistivity of silicon wafers, limiting open circuit voltage, etc. Efficiency, reducing bulk resistivity, and improving photoelectric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

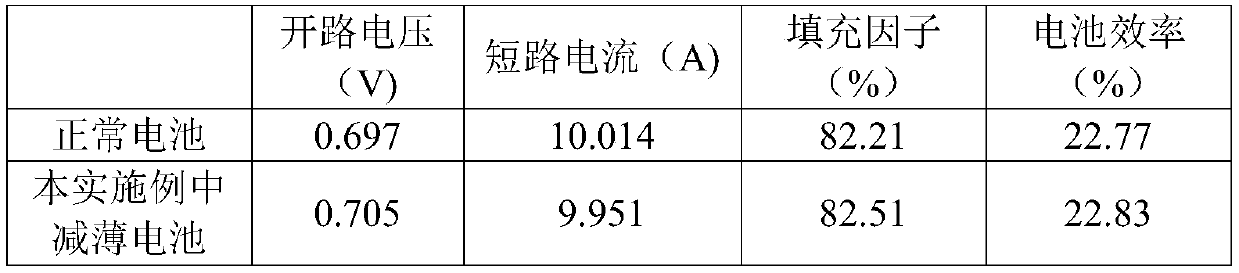

Embodiment 1

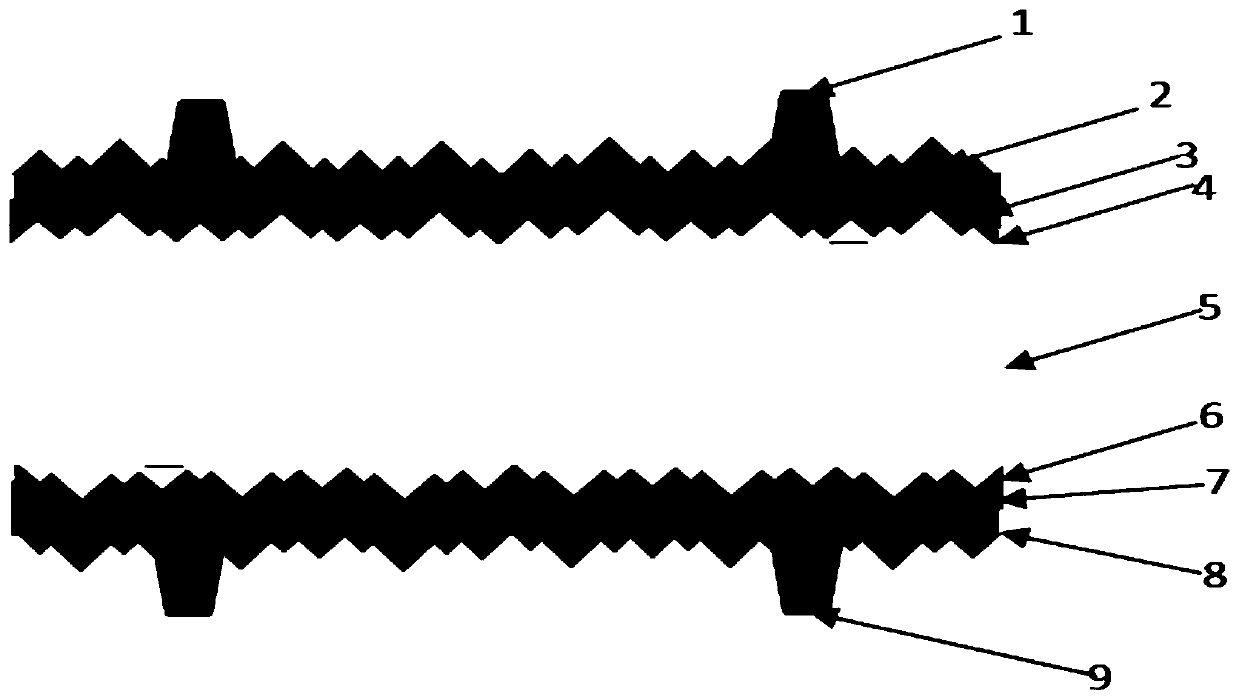

[0029] A method for preparing an alkali-etched ultra-thin N-type passivated contact crystalline silicon solar cell, comprising the steps of:

[0030] Using N-type monocrystalline silicon as the silicon substrate, first perform conventional cleaning and then use a TMAH solution with a volume concentration of 20% to thin the cleaned silicon wafer, and the process time is 650s.

[0031] The thinned silicon wafer is textured and boron diffused. After the diffusion is completed, the BSG on the back is removed on one side, and then the single-sided texturing process on the back is adopted. Then deposit a layer of 5-15nm silicon oxide layer and 150-250nm intrinsic polysilicon layer on the back side, the deposition method is PECVD.

[0032] This is followed by phosphorus diffusion, followed by dehydration of the silicon wafer, followed by deposition of aluminum oxide and silicon nitride on the front side of the silicon wafer, and silicon nitride on the back side.

[0033] Finally, sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com