Manufacturing method of solar cell

A technology of solar cells and conductive films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high equipment requirements and high prices, achieve low equipment requirements, less harm to the body and the environment, and improve short-circuit current and open-circuit voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

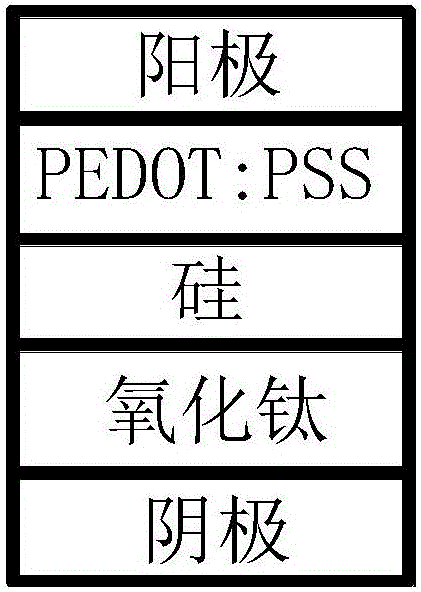

[0029] The steps of a method for preparing a solar cell provided in this embodiment are as follows:

[0030] (1) Clean the silicon wafer and etch the structure; the specific steps include: 1. Make the resistance value 0.05-0.1Ω / cm 2 After cleaning the silicon wafer, soak it in the mixed solution of 0.2M AgNO3 and 4.8M HF for 5 minutes, and then clean it with deionized water; 2. Soak the treated silicon wafer in concentrated nitric acid for 5 minutes, take it out, wash and dry it 3. Submerge the treated silicon wafer in the HF solution for 2 minutes, and then place it in a 1% tetramethylammonium hydroxide solution for etching for 40 seconds. The present invention uses silicon-organic hybrid solar cells as battery implementation examples, and the scope of solar cells is not limited to silicon-organic hybrid solar cells, including all silicon-based solar cells, solar cells such as monocrystalline silicon, polycrystalline silicon, and thin-film silicon.

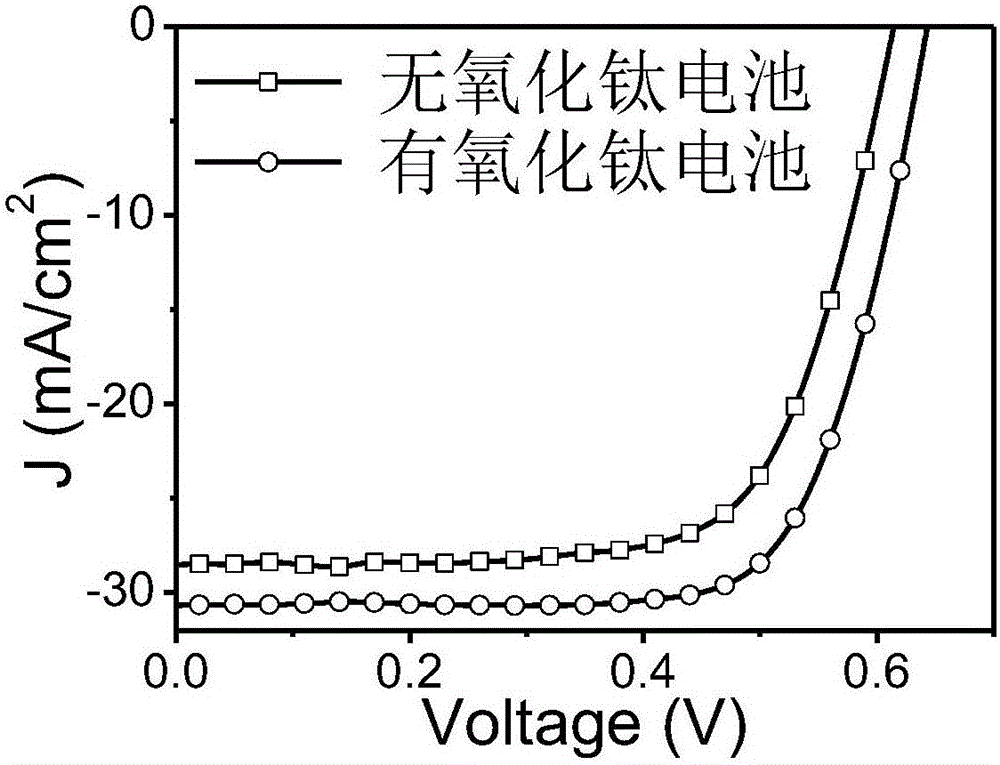

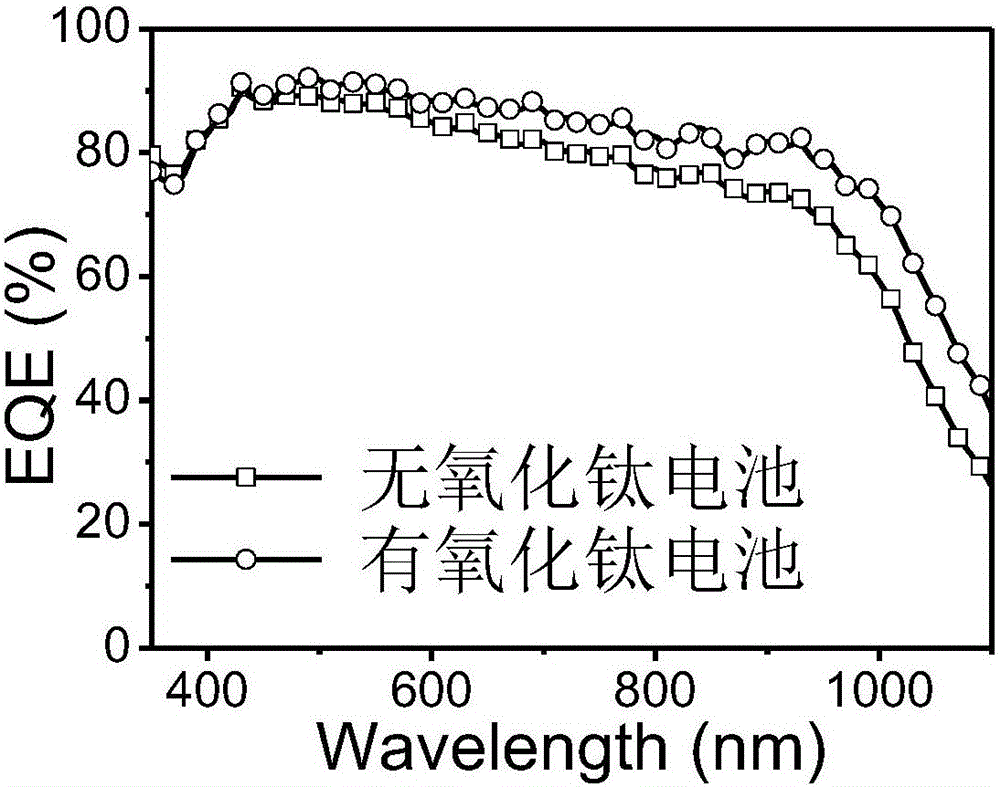

[0031] (2) Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com