Quantum dot light-emitting device and preparation method thereof

A quantum dot luminescence and device technology, applied in the field of quantum dot luminescence, can solve the problems of high luminous efficiency and QLED cannot be realized, and achieve the effects of improving luminous efficiency, reducing defect states, and suppressing fluorescence quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] On the basis of the research results, the applicant proposed the technical solution of the present application. In a typical implementation of the present application, a method for preparing a quantum dot light-emitting device is provided. The preparation method includes: providing a workpiece containing a nanocrystal layer of a quantum dot light-emitting device; The workpiece to be processed of the first layer is acid-treated to obtain a quantum dot light-emitting device.

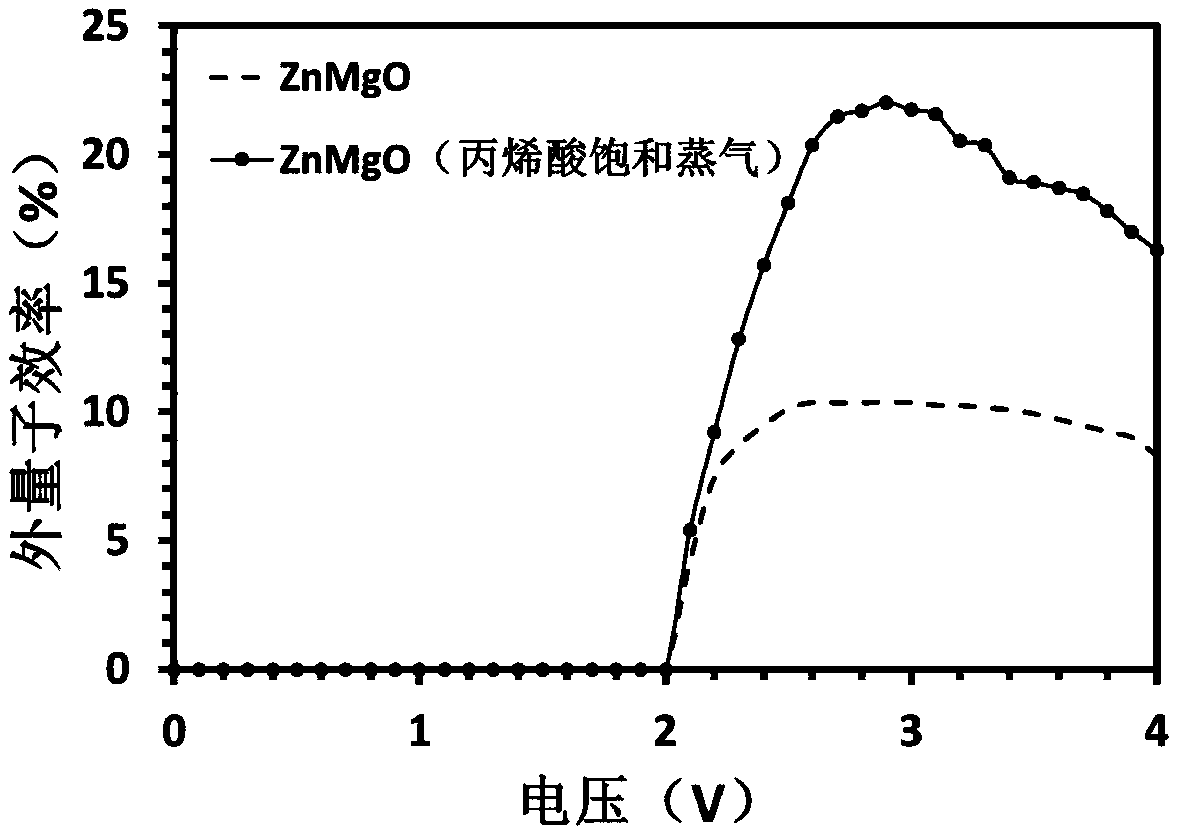

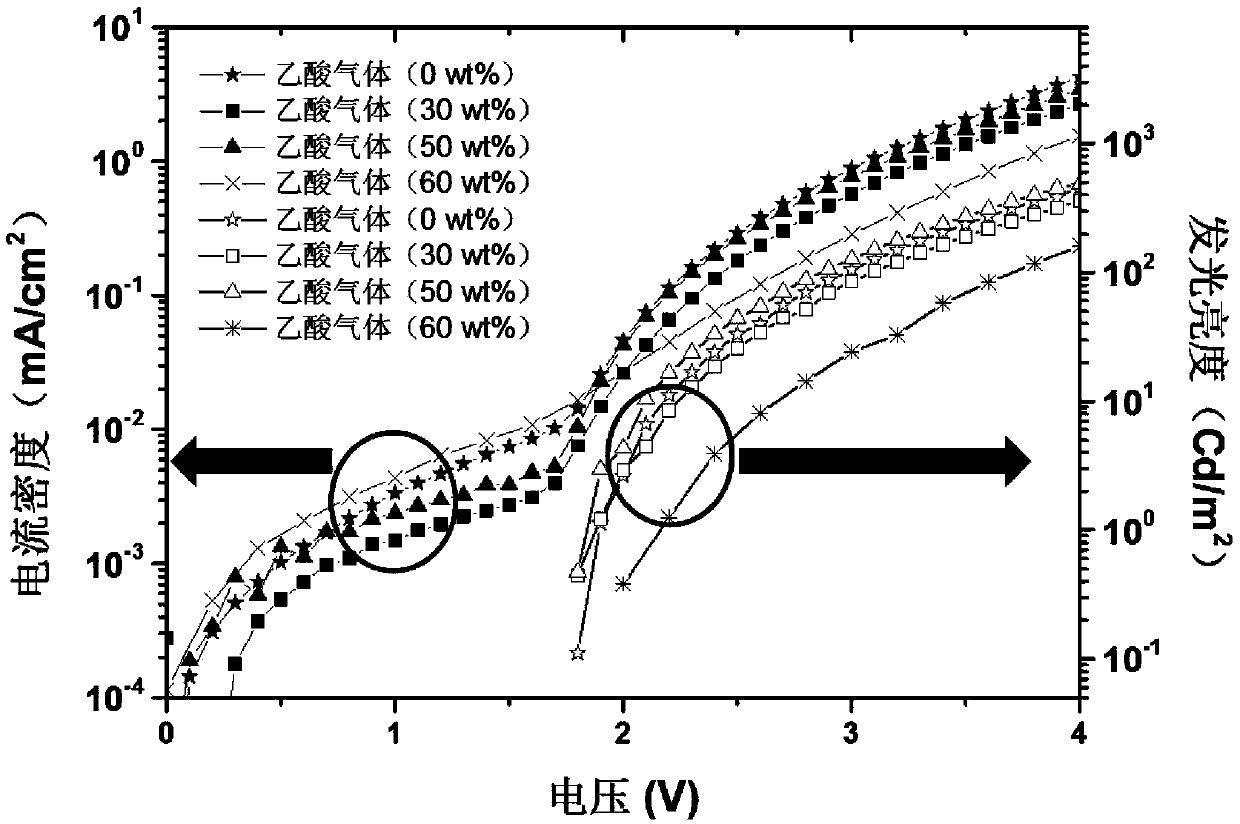

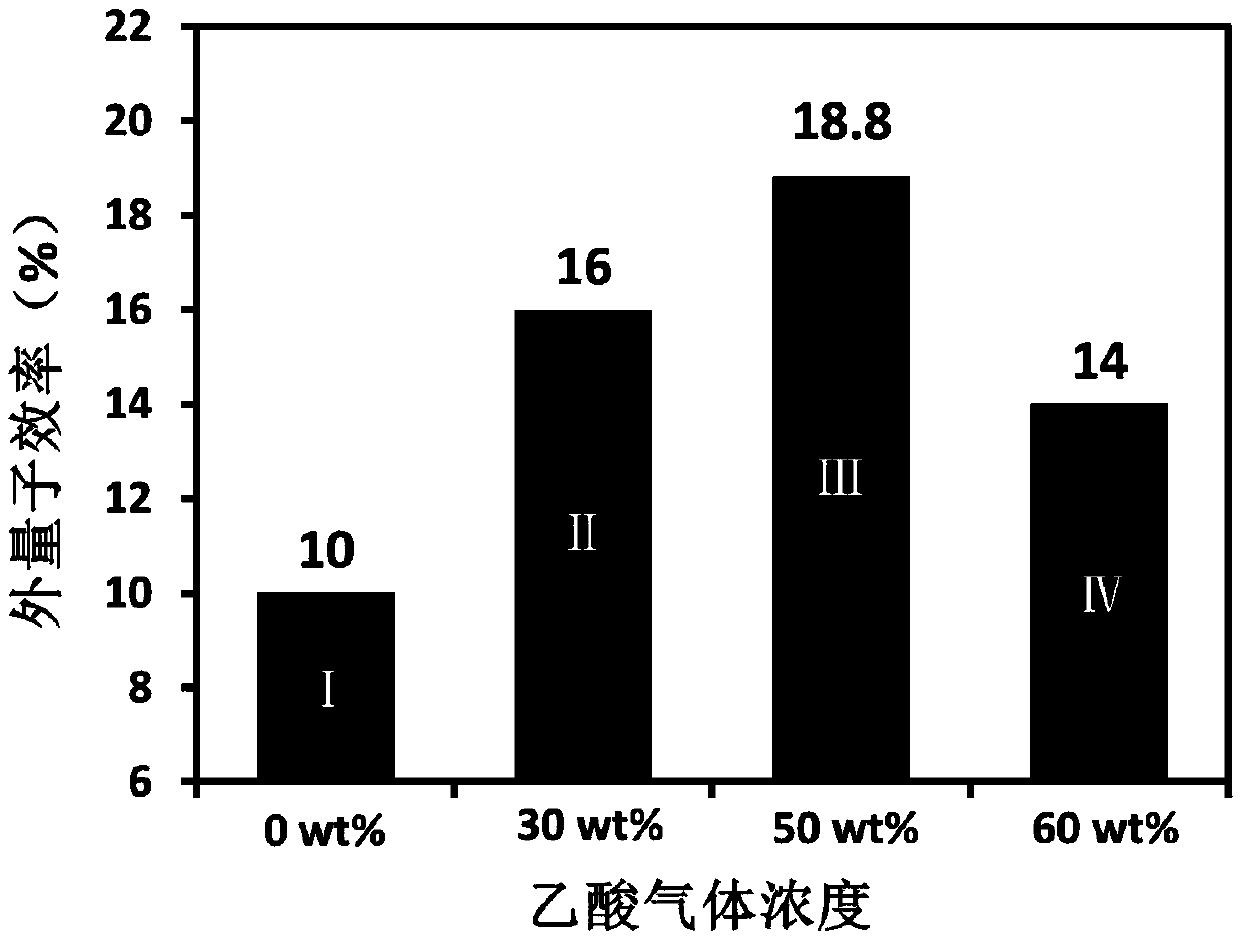

[0039] The preparation method of the quantum dot light-emitting device of the present application, by carrying out acid treatment to the workpiece to be processed containing the nanocrystal layer, on the one hand the acid and the hydroxide ion ligand on the surface of the nanocrystal (the current nanocrystal is due to the reason of the synthesis process, Its surface usually has hydroxide ion ligands) to react to generate water and acid ion ligands, reducing or eliminating the hydroxide ion ligands o...

Embodiment 11

[0089] S1. Prepare ITO glass

[0090] Put the ITO glass piece with the number engraved on the back into a glass dish filled with ethanol solution, and wipe the ITO surface clean with a cotton swab. Sonicate with acetone, deionized water, and ethanol in turn for 10 minutes, and blow dry with a nitrogen gun. Finally, place the cleaned ITO glass in oxygen plasma for 10 minutes.

[0091] S2. Preparation of Hole Injection Layer (HIL)

[0092] The cleaned ITO glass sheet is spin-coated with 30mg / ml NiO nanocrystal solution of octane phase in air respectively, the rotating speed is 3000r / min, and the spin-coating time is 45 seconds. After processing at 120°C for 20 minutes and annealing at 150°C for 30 minutes, quickly transfer the sheet to a nitrogen atmosphere glove box. S3. Preparation of hole transport layer (HTL)

[0093] TFB (8-10mg / mL, chlorobenzene solution) Continue to spin-coat the glass / ITO / NiO nanocrystal sheet with the hole transport layer of TFB, the rotation speed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com