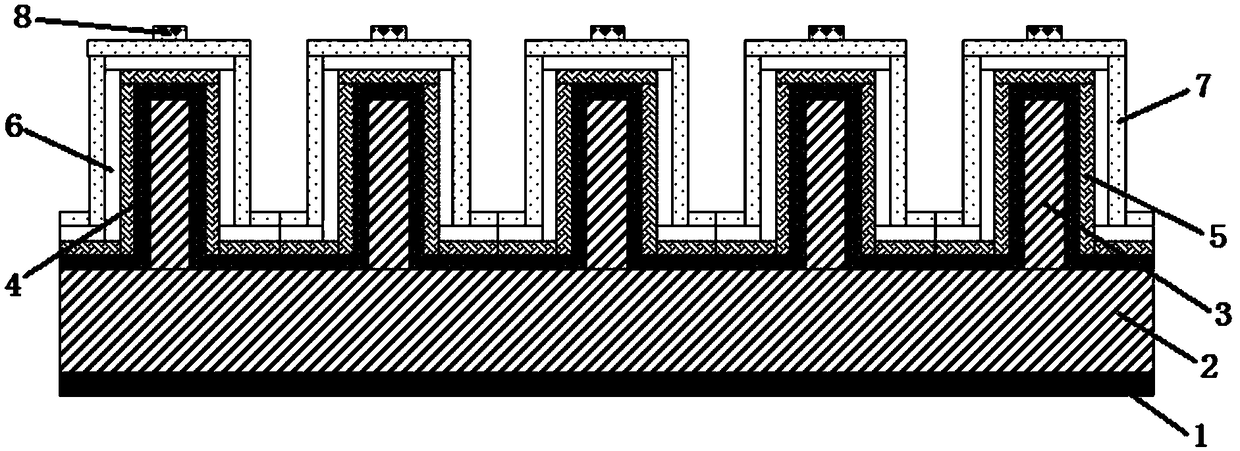

Silicon-based core-shell structure photovoltaic cell and preparation method thereof

A photovoltaic cell and core-shell structure technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of many defect states and low photoelectric conversion efficiency, and achieve the effects of reducing defect states, improving photoelectric conversion efficiency, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a silicon-based core-shell structure photovoltaic cell proposed in a specific embodiment of the present invention comprises the following steps:

[0025] (1) preparing a silicon nanowire array on the upper surface of an N-type single crystal silicon wafer, and then soaking in an HF solution to remove the natural silicon oxide on the surface of a single silicon nanowire in the silicon nanowire array;

[0026] (2) Preparation of the first interface modification layer: the upper surface of the N-type single crystal silicon wafer obtained in step (1) is spin-coated with the first mixed solution containing hafnium isobutoxide and P3HT, wherein in the first mixed solution The concentration of hafnium isobutoxide is 0.3-0.5mg / ml, the concentration of P3HT is 1-1.5mg / ml, the rotation speed of spin coating is 5500-6000 rpm, and then the first annealing treatment is performed to form the first Interface modification layer;

[0027] (3) Preparation of the s...

Embodiment 1

[0036] A method for preparing a silicon-based core-shell structure photovoltaic cell, comprising the following steps:

[0037] (1) preparing a silicon nanowire array on the upper surface of an N-type single crystal silicon wafer, and then soaking in an HF solution to remove the natural silicon oxide on the surface of a single silicon nanowire in the silicon nanowire array;

[0038](2) Preparation of the first interface modification layer: the upper surface of the N-type single crystal silicon wafer obtained in step (1) is spin-coated with the first mixed solution containing hafnium isobutoxide and P3HT, wherein in the first mixed solution The concentration of hafnium isobutoxide is 0.4 mg / ml, the concentration of P3HT is 1.2 mg / ml, the rotation speed of spin coating is 5800 rpm, and then the first annealing treatment is performed to form the first interface modification layer;

[0039] (3) Preparation of the second interface modification layer: the upper surface of the N-type ...

Embodiment 2

[0048] A method for preparing a silicon-based core-shell structure photovoltaic cell, comprising the following steps:

[0049] (1) preparing a silicon nanowire array on the upper surface of an N-type single crystal silicon wafer, and then soaking in an HF solution to remove the natural silicon oxide on the surface of a single silicon nanowire in the silicon nanowire array;

[0050] (2) Preparation of the first interface modification layer: the upper surface of the N-type single crystal silicon wafer obtained in step (1) is spin-coated with the first mixed solution containing hafnium isobutoxide and P3HT, wherein in the first mixed solution The concentration of hafnium isobutoxide is 0.5 mg / ml, the concentration of P3HT is 1 mg / ml, the rotation speed of spin coating is 6000 rpm, and then the first annealing treatment is performed to form the first interface modification layer;

[0051] (3) Preparation of the second interface modification layer: the upper surface of the N-type s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com