Core-shell quantum dot, preparation method thereof and quantum dot photoelectric device

A technology of core-shell quantum dots and optoelectronic devices, applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve problems such as poor monodispersity, reduced efficiency, and poor resistance to water and oxygen, and achieve reduced defect states and stable The effect of good sex and few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

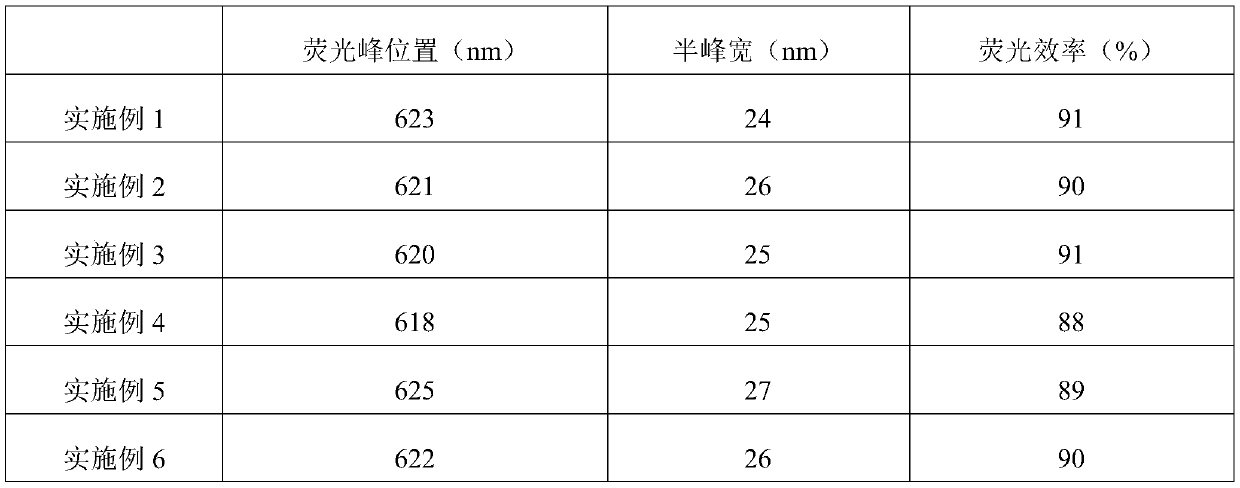

[0030] In the prior art, the step of coating the CdZnS shell on the CdSe quantum dot is to inject the sulfur precursor into the mixed solution of the cadmium precursor and the zinc precursor to react. The inventors have found that since the reactivity of the cadmium precursor is higher than that of the zinc precursor, the CdZnS shell layer has less cadmium atom content as it moves outward. The CdZnS shell layer coated in the prior art is equivalent to CdS / CdZnS containing a small amount of cadmium. / Thicker ZnS, which leads to thicker ZnS on the outside of the CdZnS shell, which increases the defect states of the CdZnS shell and deteriorates the purity of the crystal form. The coating efficiency of the shell layer is low, and the obtained core-shell quantum dots have a narrow half-width of fluorescence, a decrease in fluorescence efficiency, and poor resistance to water and oxygen. In order to solve this problem, the present invention provides a method for preparing core-shell...

Embodiment 1

[0072] Coating of the middle shell:

[0073] (1) Add 4mmol of zinc acetate, 0.2mmol of cadmium acetate, 4.4g of oleic acid and 15mL of ODE into a 100mL three-neck flask, and at 200°C, pass inert gas to exhaust for 30 minutes, and then inject the purified first excitons For a CdSe quantum dot solution with an absorption peak of 570nm and an absorbance of 50, raise the temperature to 300°C;

[0074] (2) Then quickly inject 2mL of S-TBP solution with a concentration of 0.625mmol / mL, react for 1 minute, inject 0.25mL of cadmium oleate solution with a concentration of 0.2mmol / mL, continue to react for 2 minutes, stop the reaction and cool down rapidly, and purify The obtained CdSe / CdZnS was dissolved in 1 mL of ODE.

[0075] Covering of the shell layer:

[0076] (3) Weigh basic zinc carbonate (0.66g, 1.2mmol), 2.8g oleic acid, and 10mL ODE into a 100mL three-necked flask, exhaust with inert gas for 10 minutes, raise the temperature to 280°C, and obtain a clear solution, Then inj...

Embodiment 2

[0079] The difference between embodiment 2 and embodiment 1 is that the addition amount of cadmium oleate is different in step (2).

[0080] Step (2) among the embodiment 2 is: then inject 2mL concentration rapidly and be the S-TBP solution of 0.625mmol / mL, react for 1 minute, inject 0.1mL concentration and be the cadmium oleate solution of 0.2mmol / mL, continue to react for 2 minutes, Stop the reaction and cool down quickly, purify the obtained CdSe / CdZnS and dissolve it in 1 mL of ODE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com