Heterojunction photovoltaic battery and preparing method thereof

A photovoltaic cell and heterojunction technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reducing the photoelectric conversion efficiency of organic and inorganic solar cells, incapable of large-scale application, and long methylation treatment time. , to achieve the effect of improving the photoelectric conversion efficiency, increasing the contact increase, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

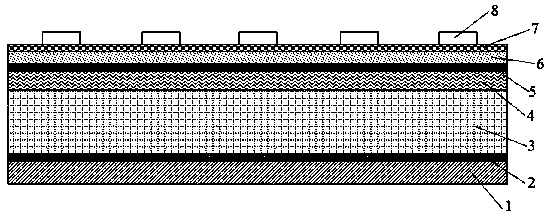

[0018] A method for preparing a heterojunction photovoltaic cell proposed in a specific embodiment of the present invention includes the following steps:

[0019] (1) Cleaning of n-type silicon wafers: ultrasonically clean n-type silicon wafers in acetone, ethanol, and deionized water for 10-15 minutes, and then place them in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 100-110°C for 50-70 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, then rinse the n-type silicon wafer with deionized water, and dry it with nitrogen for standby;

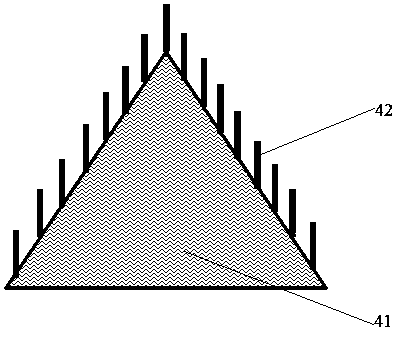

[0020] (2) Prepare a pyramid-structure textured layer on the upper surface of the n-type silicon wafer: place the n-type silicon wafer obtained in step 1 in a mixed solution of NaOH and ethanol, wherein in the mixed solution, the The mass fraction of the NaOH is 4-5%, the volume fraction of the ethanol is 12-15%, etched at 80-90°C for 40-50 minutes to obtain ...

Embodiment 1

[0029] A method for preparing a heterojunction photovoltaic cell, comprising the following steps:

[0030] (1) Cleaning of n-type silicon wafers: ultrasonically clean n-type silicon wafers in acetone, ethanol, and deionized water for 12 minutes, and then place them in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 105°C for 60 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, then rinse the n-type silicon wafer with deionized water, and dry it with nitrogen for standby;

[0031] (2) Prepare a pyramid-structure textured layer on the upper surface of the n-type silicon wafer: place the n-type silicon wafer obtained in step 1 in a mixed solution of NaOH and ethanol, wherein in the mixed solution, the The mass fraction of NaOH is 4.5%, the volume fraction of ethanol is 12%, etched at 90°C for 45 minutes to obtain the pyramid structure texture layer, and then the n-type silicon wafer is placed in...

Embodiment 2

[0040] A method for preparing a heterojunction photovoltaic cell, comprising the following steps:

[0041] (1) Cleaning of n-type silicon wafers: ultrasonically clean n-type silicon wafers in acetone, ethanol, and deionized water for 15 minutes, and then place them in concentrated H 2 SO 4 / H 2 o 2 mixed solution and heated to 110°C for 50 minutes, the concentrated H 2 SO 4 / H 2 o 2 H in the mixed solution 2 SO 4 with H 2 o 2 The volume ratio is 3:1, then rinse the n-type silicon wafer with deionized water, and dry it with nitrogen for standby;

[0042] (2) Prepare a pyramid-structure textured layer on the upper surface of the n-type silicon wafer: place the n-type silicon wafer obtained in step 1 in a mixed solution of NaOH and ethanol, wherein in the mixed solution, the The mass fraction of NaOH is 4%, the volume fraction of ethanol is 15%, etched at 85°C for 50 minutes to obtain the pyramid structure texture layer, and then the n-type silicon wafer is placed in h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com