Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous

A field effect transistor, amorphous oxide technology, applied in transistors and other directions, can solve problems such as reducing the image quality of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

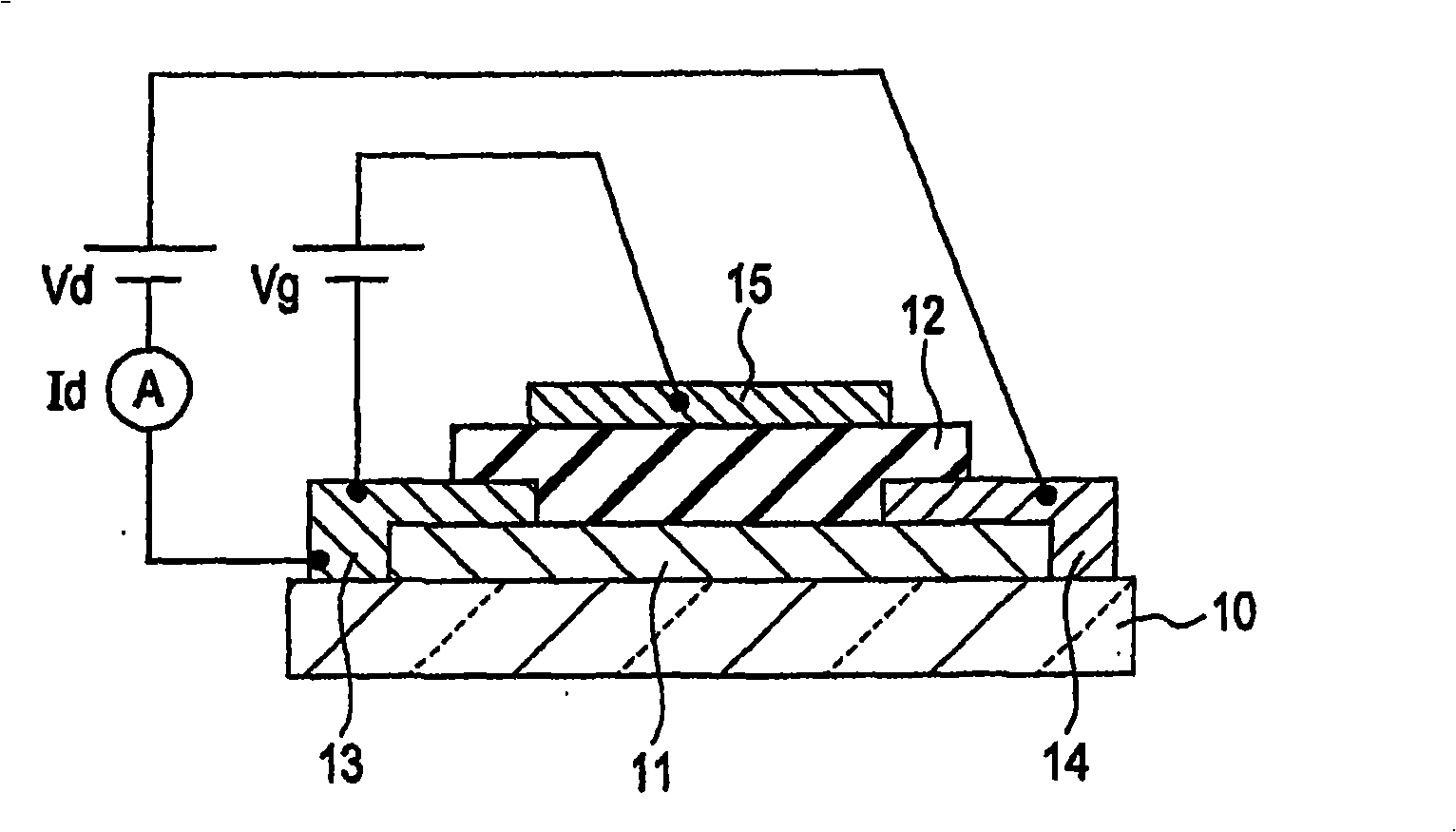

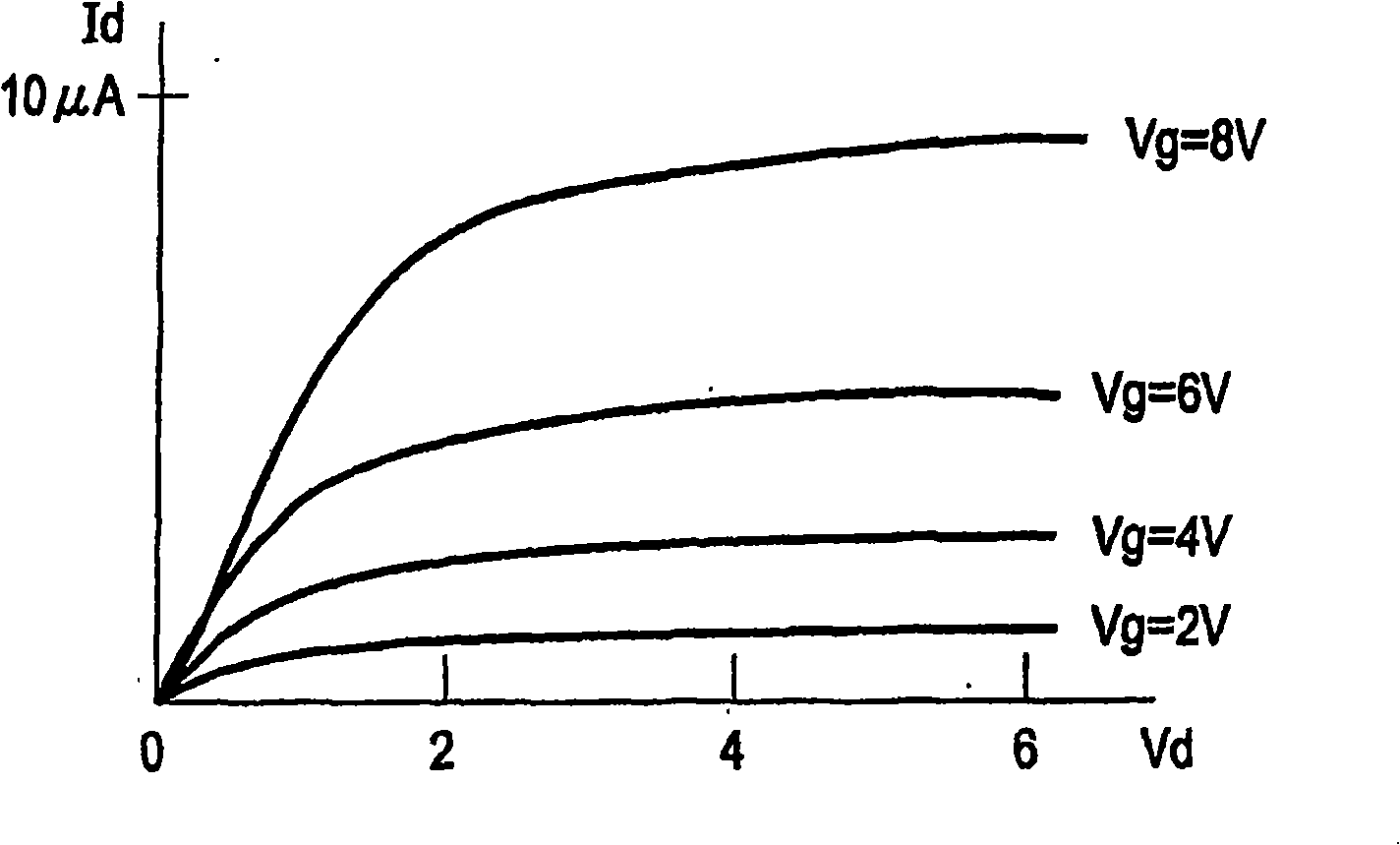

[0103] In this example, the Figure 1A The top-gate TFT shown in . In this example, the channel layer is an In-Ga-Zn-O-based amorphous oxide formed by a sputtering method in a hydrogen-containing gas atmosphere.

[0104] First, an amorphous oxide film containing hydrogen was formed as a channel layer on a glass substrate (Corning #1737 glass produced by Corning Corporation).

[0105] In this example, an In-Ga-Zn-O-based amorphous oxide film containing hydrogen was formed by high-frequency sputtering in a mixed gas atmosphere containing argon, oxygen, and hydrogen.

[0106] use as Figure 5 The sputtering device shown. In this drawing, reference numeral 51 denotes a sample, reference numeral 52 denotes a target, reference numeral 53 denotes a vacuum pump, reference numeral 54 denotes a vacuum gauge, reference numeral 55 denotes a substrate holder, and reference numeral 56 denotes a A gas flow rate controller provided for each gas introduction system, reference numeral 57 den...

example 2

[0133] In this example, an amorphous oxide film containing hydrogen to be used for a channel layer of a thin film transistor will be described. First, an insulating film of amorphous oxide is formed on a quartz substrate.

[0134] The film-forming method of the amorphous oxide was performed in accordance with the film-forming method described in Example 1. Target (material source) is InGaO 3 (ZnO), and the total pressure in the gas environment during film formation is 0.3Pa. In this step, the gas flow ratio is set as Ar:O 2 =95:5, thus the partial pressure of oxygen corresponds to 0.015Pa. In addition, hydrogen gas was not provided. The film thickness was set to about 400 nm. When the resistance of the thin film thus formed was measured by the four-probe method, the electric conductivity was not greater than the measurement limit (0.0001 S / cm or less), and thus it was confirmed that the thin film was an insulating film.

[0135] Next, hydrogen ion implantation was perfor...

example 3

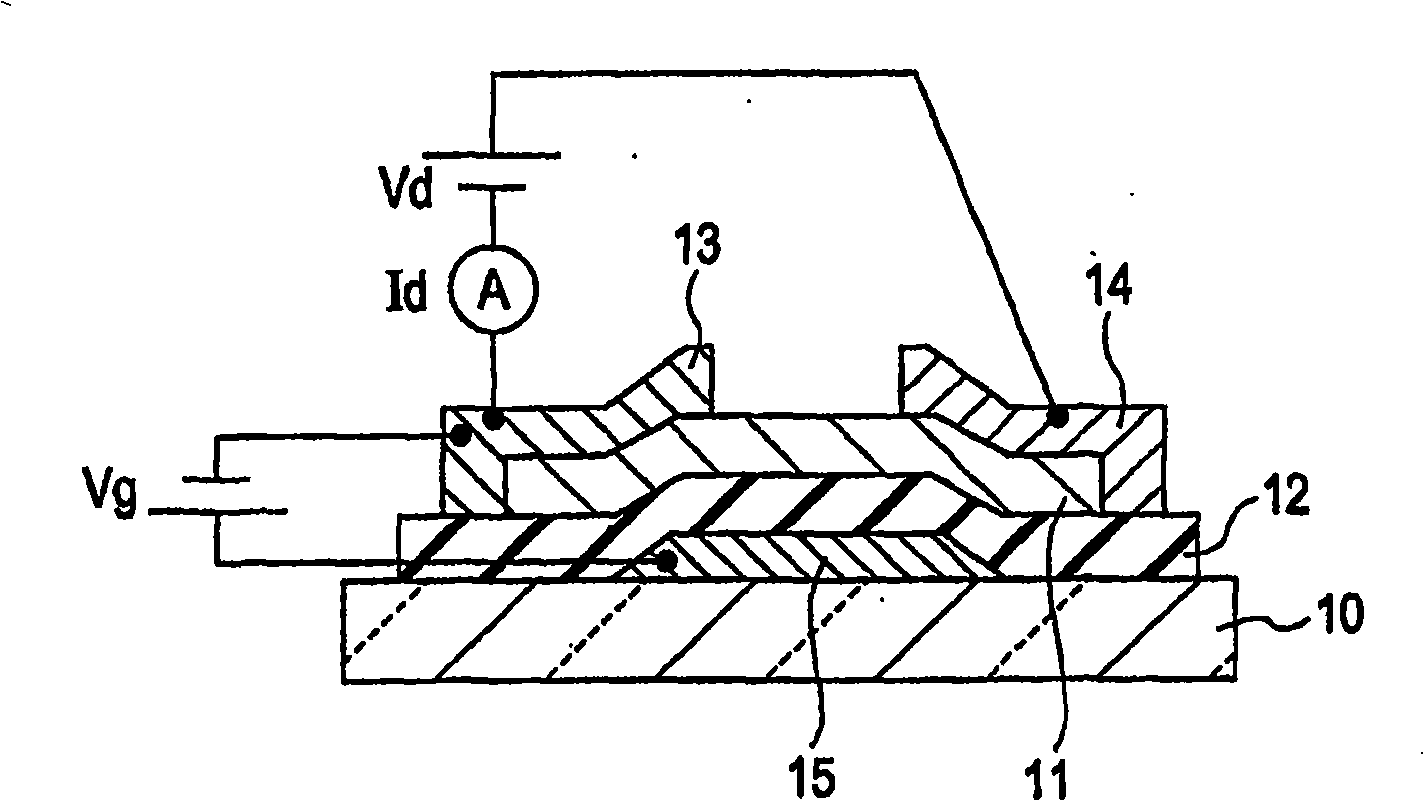

[0143] In this example, the Figure 1A The top-gate TFT shown in . In this case, an amorphous oxide containing hydrogen (or deuterium) was formed by ion-implanting hydrogen or deuterium into an In-Ga-Zn-O-based amorphous oxide formed by a pulsed laser deposition method (PLD method). channel layer.

[0144] First, an In-Zn-Ga-O-based amorphous oxide film was formed on a glass substrate (Corning #1737 glass produced by Corning Corporation) by the PLD method.

[0145] InGaO 3 (ZnO) 4 A polycrystalline sintered material was used as a target, and an In-Zn-Ga-O-based amorphous oxide film was deposited. The oxygen partial pressure during film formation was 7 Pa. The power of the KrF excimer laser is 1.5×10 -3 mJ / cm 2 / pulse, the pulse width is 20 ns, and the repetition rate is 10 Hz. In addition, the substrate temperature was not heated and kept at room temperature of about 25°C.

[0146] According to the results of fluorescent x-ray (XRF) analysis, the metal composition rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com