Multifunctional sensor with microstructure fiber surface plasma resonance and preparation method thereof

A technology of surface plasmon and micro-structured optical fiber, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems of limited application, achieve good sensing characteristics, high measurement accuracy, and unique magneto-optical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

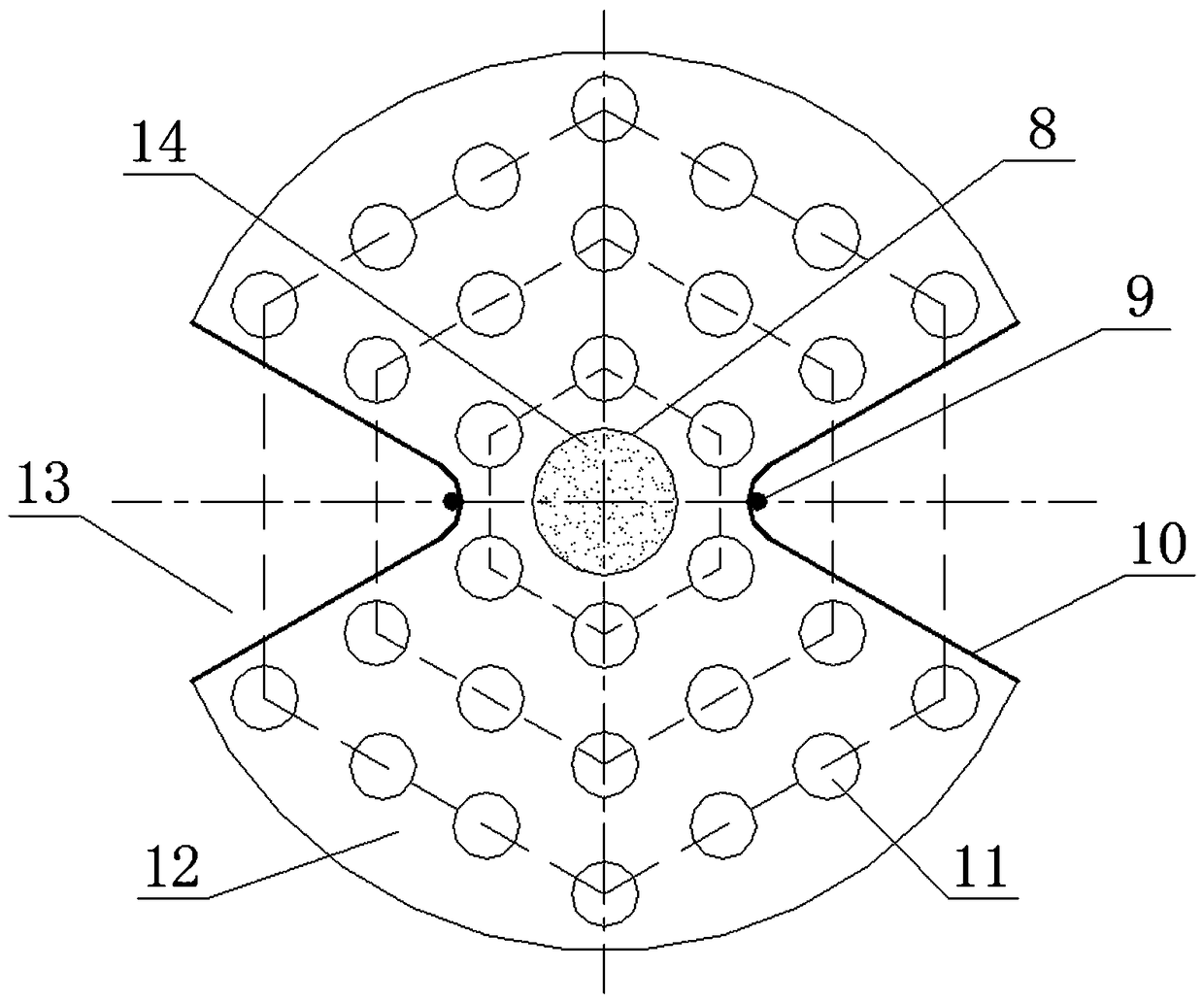

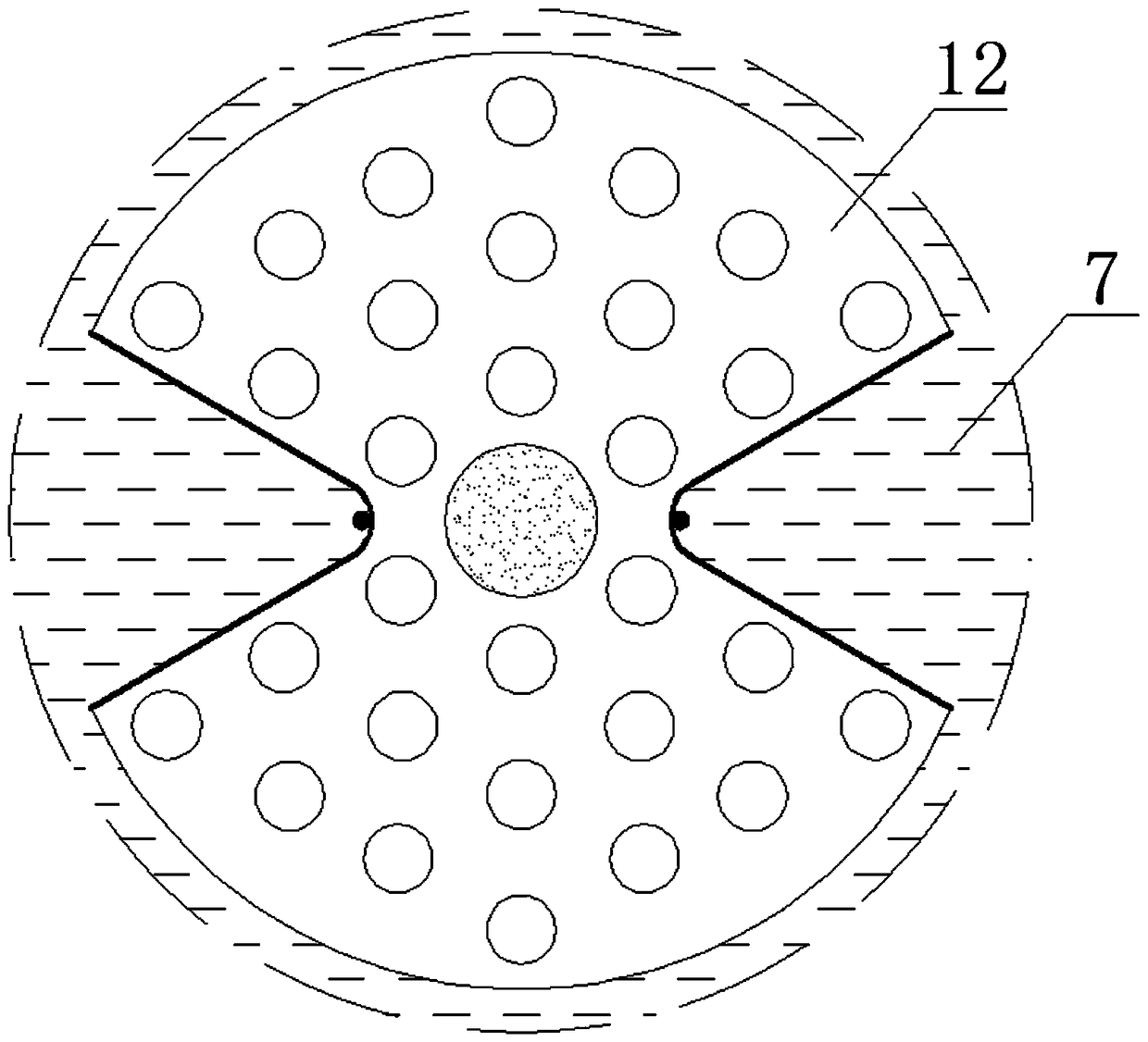

[0032] refer to figure 1 , a kind of microstructure optical fiber surface plasmon resonance multifunctional sensor, the photonic crystal fiber base 12 both sides of this optical fiber sensor are provided with fan-shaped opening 13, the surface of described fan-shaped opening 13 is coated with gold film 10, adopts magnetron sputtering method Deposit gold film 10 on the plane of two fan-shaped openings 13, the thickness of preparation gold film is 30~50nm, because the variation of gold film 10 temperature can make the absorption peak position of optical fiber output end spectrum change, so gold film 10 is used as The temperature sensing detection layer of surface plasmon resonance; the tip of the fan-shaped opening 13 bottom is provided with a silver nanowire 9, which is used to enhance the surface plasmon resonance effect and improve the sensitivity of the sensor; in the core 8 of the photonic crystal fiber substrate 12 A magnetic fluid 14 is provided, and cladding air holes 11...

Embodiment 2

[0034] A preparation method of a microstructure optical fiber surface plasmon resonance multifunctional sensor, the preparation method comprising the following steps:

[0035] Step 1: Take a hollow photonic crystal fiber, remove the outer coating layer, cut and flatten the end faces of the two fibers with a fiber cutter;

[0036] Step 2: Polish the photonic crystal optical fiber treated in step 1 by polishing the base block with an arc-shaped groove on the side of the optical fiber, first fix the optical fiber on a glass base block with an arc-shaped groove on it with glue, Fix the optical fiber with epoxy glue, then use an optical polishing machine to polish the optical fiber, and polish the fan-shaped openings on both sides of the photonic crystal fiber base. After polishing, dissolve the epoxy glue used for fixing with epoxy glue solution , so as to take out the polished photonic crystal fiber;

[0037] Step 3: Fill the silver nanowires with the method of extracting and inje...

Embodiment 3

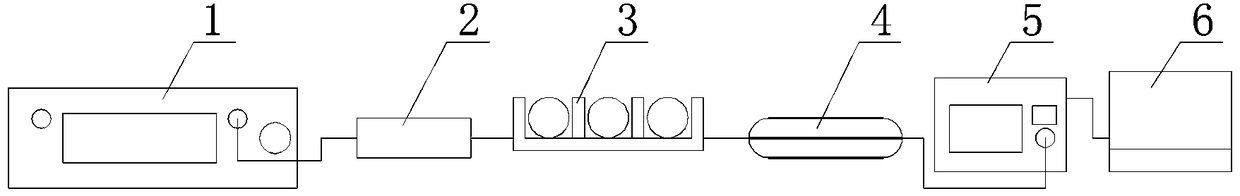

[0042] refer to Figure 2-6 , a measurement method using a microstructure optical fiber surface plasmon resonance multifunctional sensor, the measurement method is: the measurement equipment mainly includes a wide-spectrum light source 1, a polarizer 2, a polarization controller 3, and a microstructure optical fiber surface plasmon resonance multifunctional sensor. Sensor 4, spectrometer 5 and computer 6; Described wide-spectrum light source 1 is connected with common single-mode optical fiber at one end of microstructure optical fiber surface plasmon resonance multifunctional sensor 4 through optical fiber connector, common single-mode optical fiber and polarizer 2 and polarization The controller 3 is connected, and the polarization controller 3 is adjusted to obtain the required polarized light, and the ordinary single-mode optical fiber at the other end enters the spectrometer 5, and the spectrometer 5 is connected to the computer 6;

[0043] 1. Use a supercontinuum fiber l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com