A microstructure fiber Bragg grating gas sensor and its detection device

A technology of microstructure optical fiber and Bragg grating, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of difficult absorption optical path, complex device, and insufficient compact structure, and achieve good anti-interference, suitable for complex conditions, and simple and practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

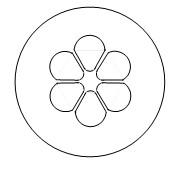

[0019] According to different light guiding mechanisms, microstructured optical fibers are divided into two types: total reflection type and photonic bandgap type. Due to the different structures, the energy distribution of the light wave evanescent field in the hole is also different. Generally, the evanescent field energy in the hole of a total reflection fiber photonic crystal accounts for about 10% to 40% of the total energy. In order to realize the writing of the grating and ensure a strong evanescent field in the hole, choose a similar figure 1 The total reflection microstructured fiber is shown as an air chamber. This optical fiber structure has a strong evanescent field, which can improve the detection sensitivity.

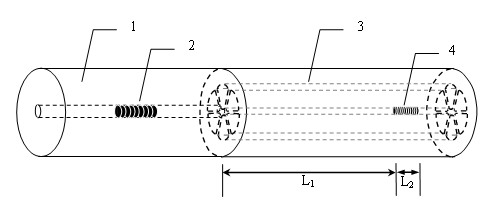

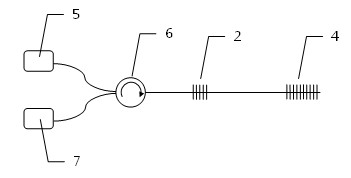

[0020] Such as figure 2 As shown, two Bragg gratings 2 and 4 are fabricated on the single-mode fiber 1 and the microstructured fiber 3 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com