A waste water and waste gas photodegradation apparatus and system thereof

A photodegradation and waste gas technology, which is applied in energy waste water treatment, light water/sewage treatment, etc., can solve the problems of inappropriate large-scale treatment of waste water and waste gas, easy to break, etc. The effect of improving the photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

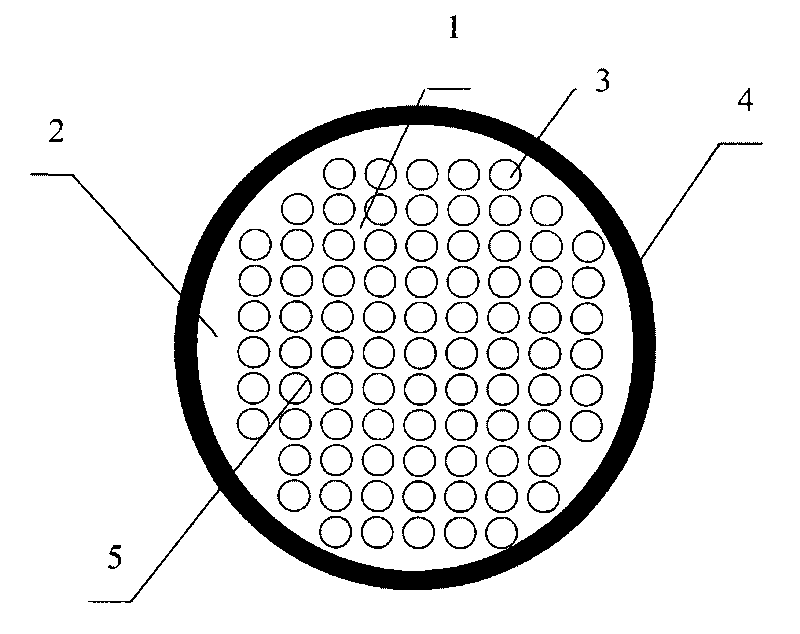

[0020] see figure 1 , the waste water and waste gas photodegradation device of the present invention includes a microstructure polymer optical fiber monomer 1 for the photodegradation of waste water and waste gas. The matrix 2 is arranged in the outer cladding 4, and the optical fiber matrix 2 is provided with a channel 3, and the inner surface of the channel 3 is provided with a titanium dioxide nanoparticle layer 5, and the preferred method is to arrange the titanium dioxide nanoparticles on the inner surface of the channel 3 in the form of a film superior.

[0021] There is at least one tunnel 3 and there may be hundreds of tunnels. When there are hundreds of tunnels 3, the tunnels 3 form a periodic distribution of the characteristics of the microstructured optical fiber.

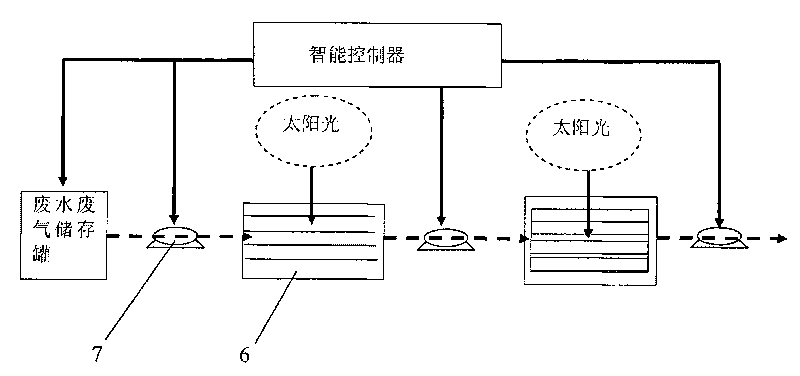

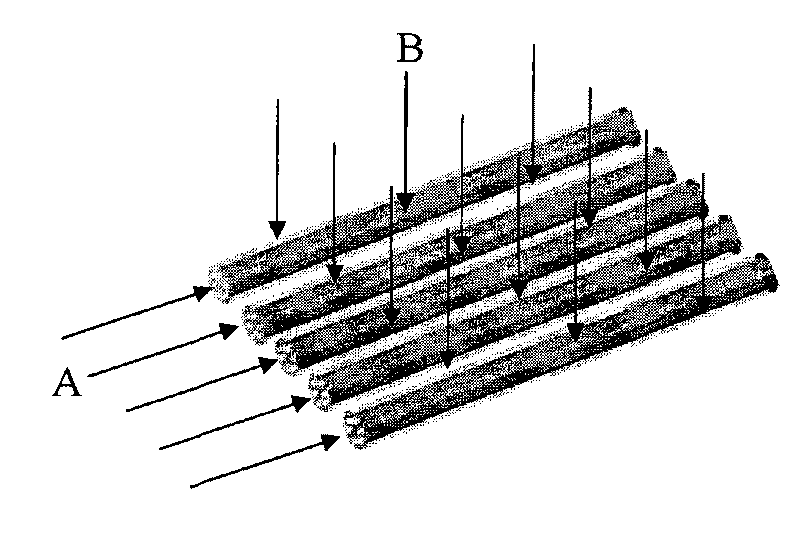

[0022] see figure 2 , using sunlight as a light source from the direction of the optical fiber cladding of the microstructure polymer optical fiber monomer 1 forming the waste water and waste gas phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com