Sensing head of fluorescent fiber sensor and preparation method of sensing head

A fluorescent optical fiber and sensor technology, applied in the field of sensor heads, can solve problems such as large sample volume, and achieve the effects of improving light stability, sensitivity, sensitivity and sensor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

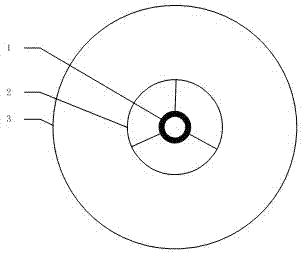

[0021] A sensing head of a fluorescent optical fiber sensor, its structure schematic diagram is as follows figure 1 As shown, it is a wheel-shaped microstructure, including a core 1, a cladding 3 and an air hole 2, the core 1 and the cladding 3 are connected by 3 tie bars, and the inner wall of the air hole 2 is coated with There is a layer of nano-gold / methyl methacrylate with a thickness of 20nm.

[0022] The preparation method of the sensing head of the above-mentioned a kind of fluorescent optical fiber sensor specifically comprises the following steps:

[0023] (1) First, pour 500ul of 0.1 mM nano-gold phosphate buffer solution into 2ml of dichloromethane solvent, then pour 300ul of dodecyl mercaptan into the above solution, and stir for 1min with a magnetic stirrer , suck out the nano-gold with a straw, place it in an oven at 75°C for 6 hours to evaporate the solvent, then pour 1ml of dichloromethane into the evaporated gold nano-gold, the solution turns red, indicating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com