Lifetime extending and performance improvements of micro-structured fibres via high temperature loading

A microstructure and fiber technology, applied in the direction of microstructure optical fiber, cladding optical fiber, nonlinear optics, etc., can solve problems such as fiber damage and system catastrophic failure, and achieve the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

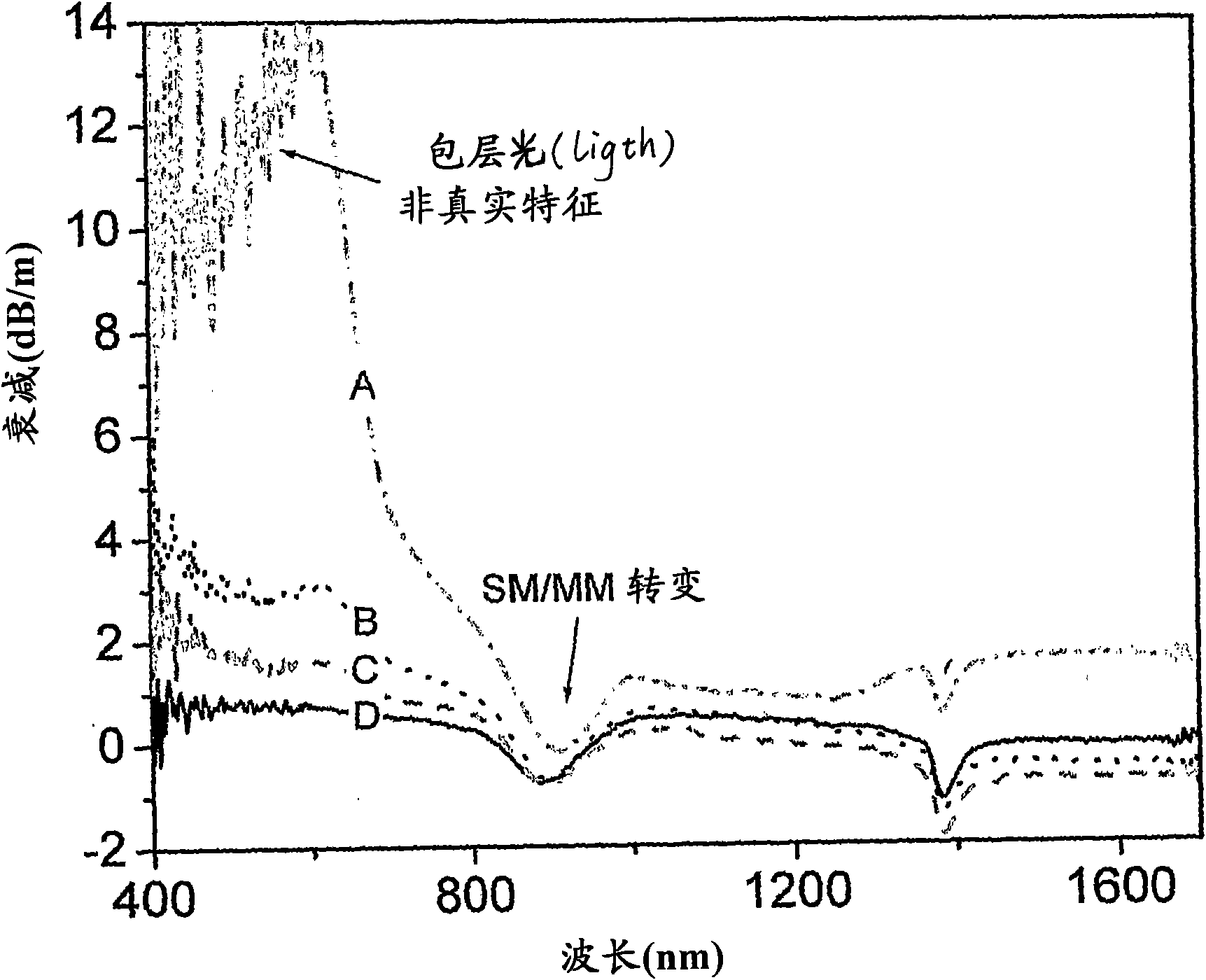

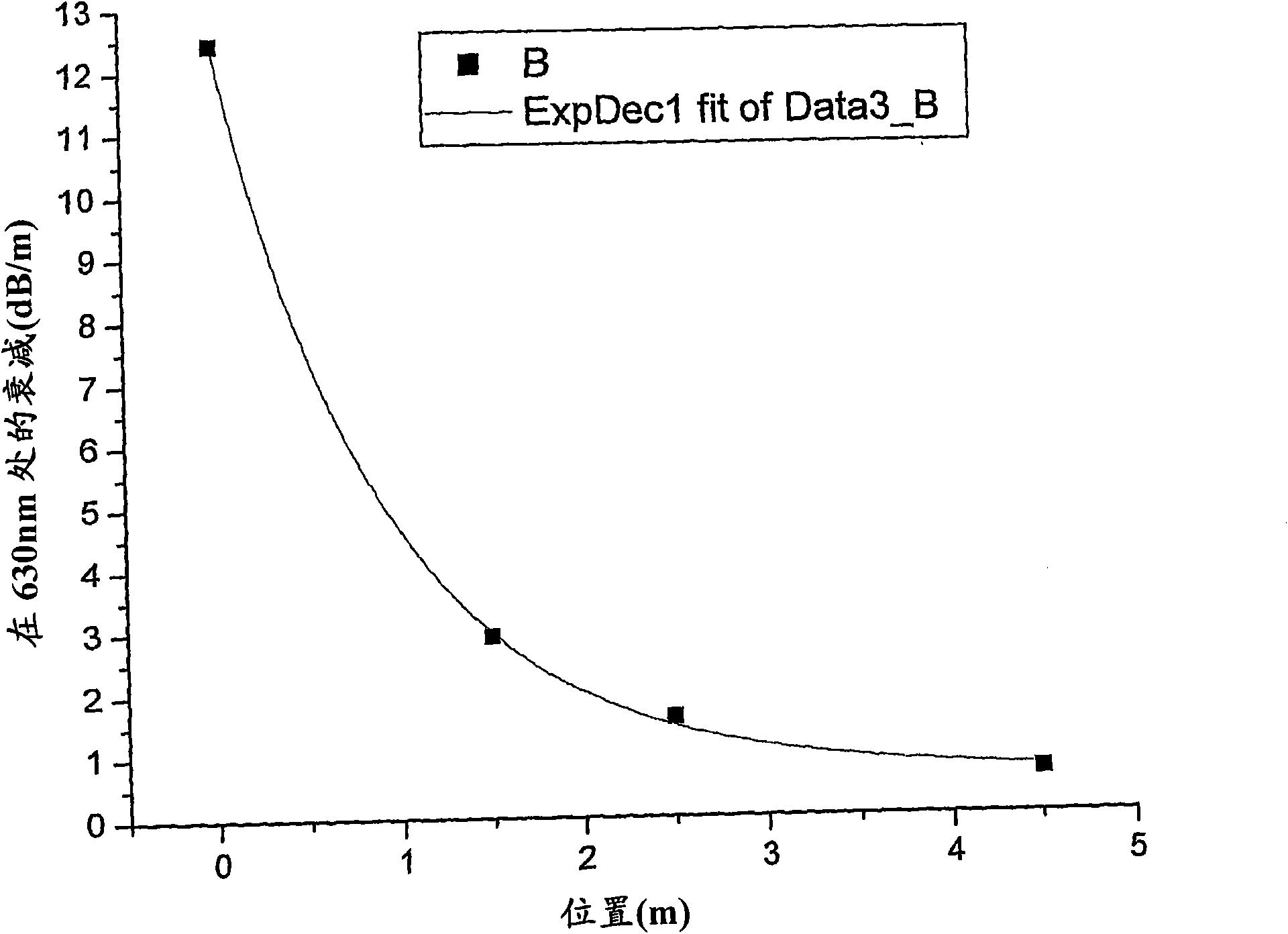

[0053] In the following the invention will be discussed based on the measured data. The conclusions drawn from these should not be considered as limiting to the specific cases of the experiments below, but rather as illustrations of the results obtainable by the present invention.

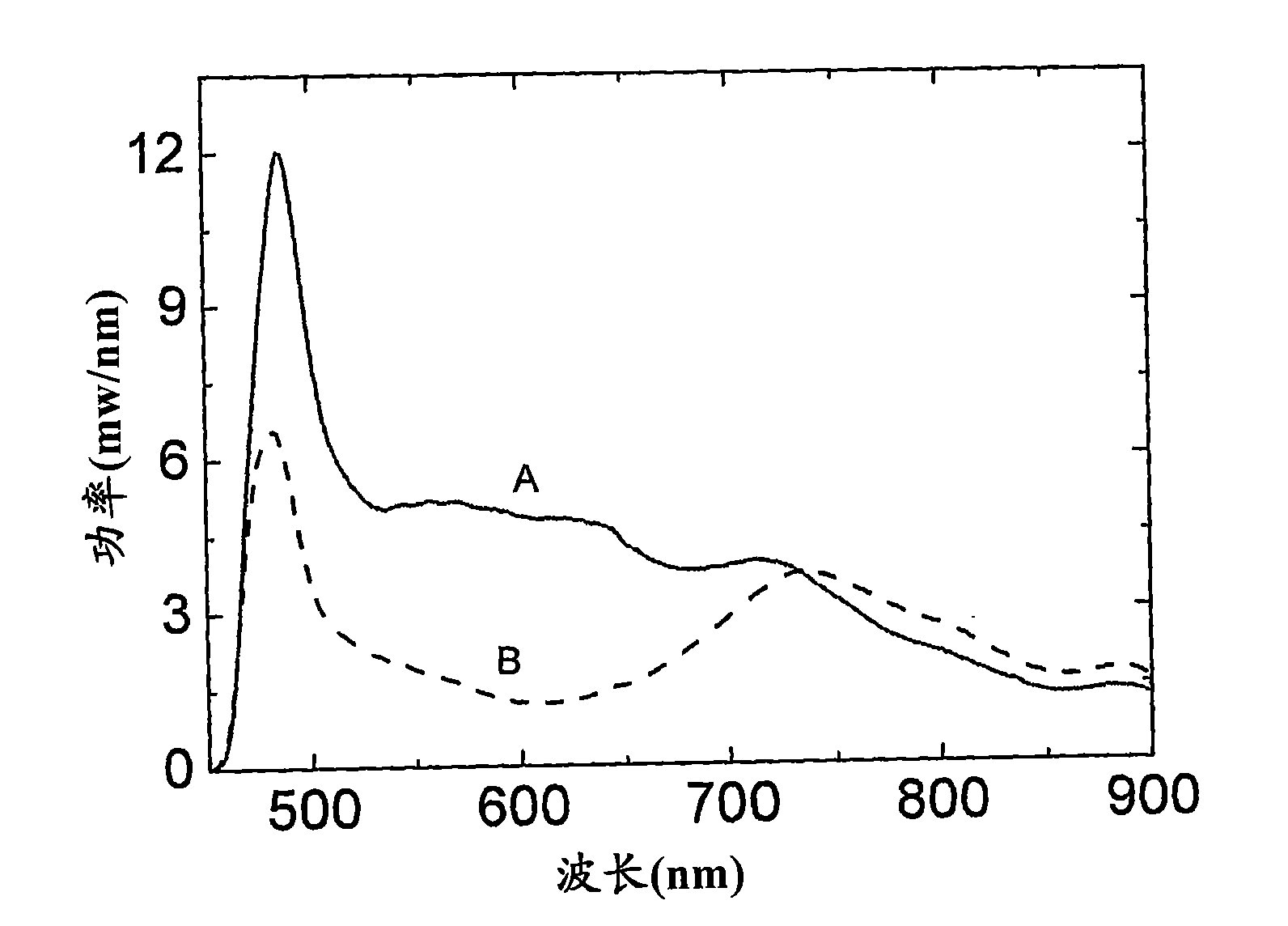

[0054] The data measured below were obtained for a supercontinuum light source comprising a pump source and a nonlinear microstructured silica fiber. The fiber was pumped at 1064nm with 8ps pulses at a repetition rate of 80MHz providing 15W input average power (23kW peak power). The fibers have a mode field diameter of 3.5 μm and are approximately 7 meters in length.

[0055] It is preferred that the length of the fiber be kept short to keep consumption of the fiber to a minimum while still providing sufficient length to allow the nonlinear processes underlying the supercontinuum to provide the desired spectrum. This length usually depends on the shape of the pulse, since shorter fibers are usual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com