Temperature sensor based on microstructure fibers, manufacturing method of temperature sensor, and temperature measuring device

A technology of temperature sensor and micro-structure optical fiber, applied in the field of temperature sensor, can solve the problems of decreased fluorescence intensity, narrow adjustable range, weak fluorescence intensity, etc., and achieve the effects of stable fluorescence intensity, extended measurement range, and wide excitation wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

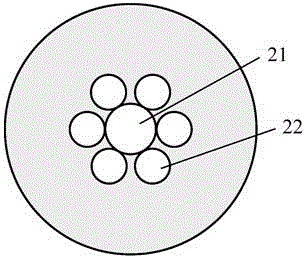

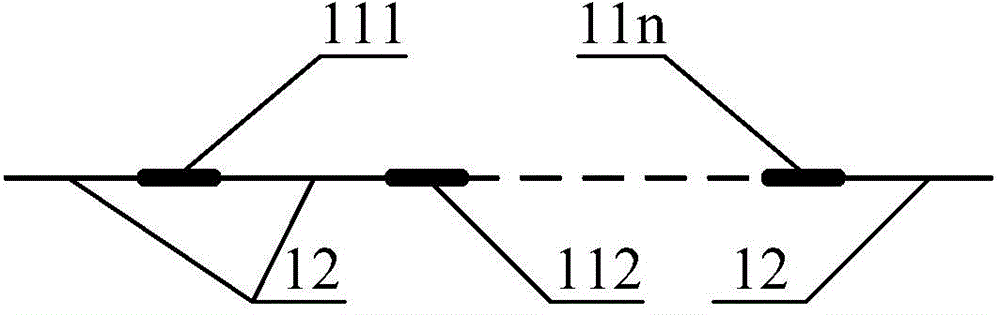

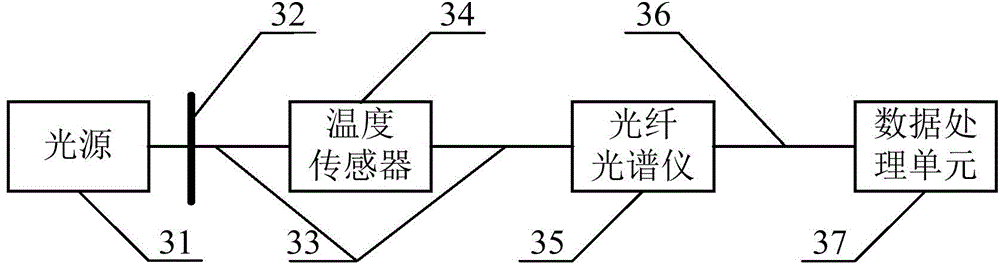

[0035] The present invention realizes temperature sensing based on the fluorescent temperature effect of quantum dots added in microstructure optical fiber pores; the quantum dot solution is filled in the microstructure optical fiber pores or quantum dot film is coated on the pores wall, when the excitation light is transmitted to the microstructure When the optical fiber is structured, the quantum dot is excited to generate fluorescence, and the temperature is measured by using the functional relationship between the fluorescent parameter and the temperature; by connecting multiple sections of micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com