A method for preparing silica/shellac composite particles containing methylene blue with high fluorescence intensity assisted by heat treatment

A technology of methylene blue and silicon dioxide, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of high fluorescence intensity, low toxicity, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

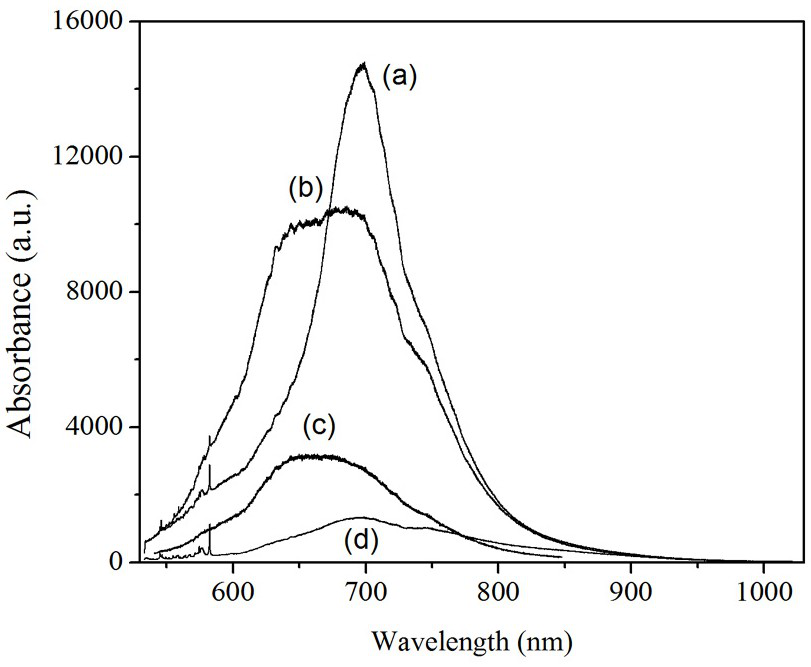

Image

Examples

Embodiment 1

[0015] (1) Add 92 ml of absolute ethanol, 17.2 ml of water, 2.48 ml of concentrated ammonia water and 0.10 g of methylene blue to the beaker in sequence. After stirring for 15 minutes, add 3.44 ml of ethyl orthosilicate. After stirring for 4 hours, centrifuge to obtain the sediment , the precipitate was first washed twice with 120 ml of ethanol, and then washed once with 20 ml of acetate buffer solution of pH = 3.6, and then the sediment obtained by centrifugation was dried at 70°C for 24 hours to obtain the Silica particles of methylene blue;

[0016] (2) Dissolving shellac in ethanol to prepare a shellac solution, wherein the concentration of shellac is 10 grams per liter, put the silica particles containing methylene blue prepared in step (1) into 10 ml of shellac In the solution, the concentration of silica particles containing methylene blue was 10 grams per liter, and after ultrasonic treatment for 5 minutes, 30 milliliters of phosphate buffer (pH=7.2~7.4) was added at a...

Embodiment 2

[0019] (1) Add 92 ml of absolute ethanol, 17.2 ml of water, 2.48 ml of concentrated ammonia water and 0.10 g of methylene blue to the beaker in sequence. After stirring for 15 minutes, add 3.44 ml of ethyl orthosilicate. After stirring for 4 hours, centrifuge to obtain the sediment , the precipitate was first washed twice with 120 ml of ethanol, and then washed once with 20 ml of acetate buffer solution of pH = 3.6, and then the sediment obtained by centrifugation was dried at 70°C for 24 hours to obtain the Silica particles of methylene blue;

[0020] (2) Dissolving shellac in ethanol to prepare a shellac solution, wherein the concentration of shellac is 10 grams per liter, put the silica particles containing methylene blue prepared in step (1) into 10 ml of shellac In the solution, the concentration of silica particles containing methylene blue was 10 grams per liter, and after ultrasonic treatment for 5 minutes, 30 milliliters of phosphate buffer (pH=7.2~7.4) was added at a...

Embodiment 3

[0023] (1) Add 92 ml of absolute ethanol, 17.2 ml of water, 2.48 ml of concentrated ammonia water and 0.10 g of methylene blue to the beaker in sequence. After stirring for 15 minutes, add 3.44 ml of ethyl orthosilicate. After stirring for 4 hours, centrifuge to obtain the sediment , the precipitate was first washed twice with 120 ml of ethanol, and then washed once with 20 ml of acetate buffer solution of pH = 3.6, and then the sediment obtained by centrifugation was dried at 70°C for 24 hours to obtain the Silica particles of methylene blue;

[0024] (2) Dissolving shellac in ethanol to prepare a shellac solution, wherein the concentration of shellac is 10 grams per liter, put the silica particles containing methylene blue prepared in step (1) into 10 ml of shellac In the solution, the concentration of silica particles containing methylene blue was 10 grams per liter, and after ultrasonic treatment for 5 minutes, 30 milliliters of phosphate buffer (pH=7.2~7.4) was added at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com