A method for preparing methylene blue-containing silica particles with high fluorescence intensity by hydrothermal method

A technology of methylene blue and silicon dioxide, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., to achieve the effect of simple process method, simple device and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

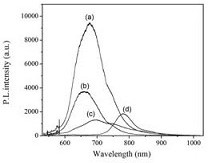

Image

Examples

Embodiment 1

[0013] (1) Add ammonia water and methylene blue in sequence to the mixed solution containing water and ethanol, stir for 15 minutes and then add tetraethyl orthosilicate, where the volumes of water, ethanol, ammonia water and tetraethyl orthosilicate are 17.2:92:2.48: 3.44 milliliters, the concentration of methylene blue is 2.32 millimoles per liter, after stirring for 4 hours, centrifuge to obtain the sediment, the sediment is first washed twice with ethanol, and then washed once with the acetate buffer solution of pH=3.6, wherein, The volumes of ethanol and acetate buffer solution used for washing are 120 milliliters and 20 milliliters respectively, and then the precipitate obtained is dried at 70° C. for 24 hours to obtain silica particles containing methylene blue;

[0014] (2) Put the methylene blue-containing silica particles prepared in step 1 into 35 ml of deionized water so that the concentration of the methylene blue-containing silica particles is 2.86 grams per liter...

Embodiment 2

[0016] (1) Add ammonia water and methylene blue in sequence to the mixed solution containing water and ethanol, stir for 15 minutes and then add tetraethyl orthosilicate, where the volumes of water, ethanol, ammonia water and tetraethyl orthosilicate are 17.2:92:2.48: 3.44 milliliters, the concentration of methylene blue is 2.32 millimoles per liter, after stirring for 4 hours, centrifuge to obtain the sediment, the sediment is first washed twice with ethanol, and then washed once with the acetate buffer solution of pH=3.6, wherein, The volumes of ethanol and acetate buffer solution used for washing are 120 milliliters and 20 milliliters respectively, and then the precipitate obtained is dried at 70° C. for 24 hours to obtain silica particles containing methylene blue;

[0017] (2) Put the methylene blue-containing silica particles prepared in step 1 into 35 ml of deionized water so that the concentration of the methylene blue-containing silica particles is 2.86 grams per liter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com