Hollow-core photonic band-gap fiber based on isolated anti-resonance layers

A photonic band gap, isolation and anti-harmonic technology, applied in cladding fibers, glass fibers, optical waveguides, etc., can solve the problems of increasing the mode field diameter, increasing the core wall thickness, and roughening the surface of the core wall. The effect of limiting, suppressing coupling, and reducing scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A hollow-core photonic bandgap fiber based on an isolation anti-resonance layer proposed by the present invention will be further described below with reference to the accompanying drawings.

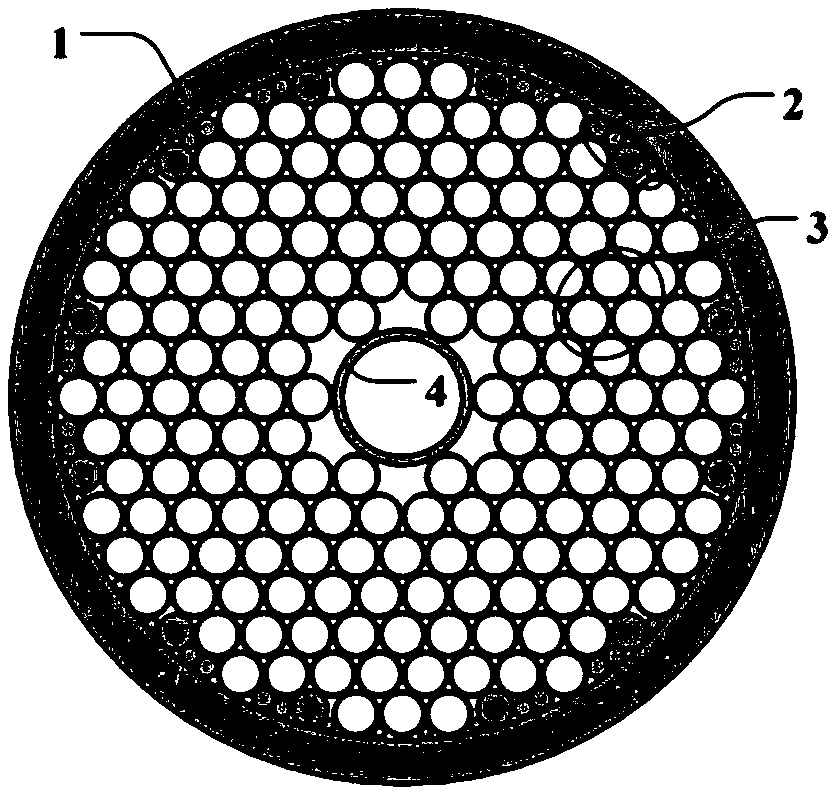

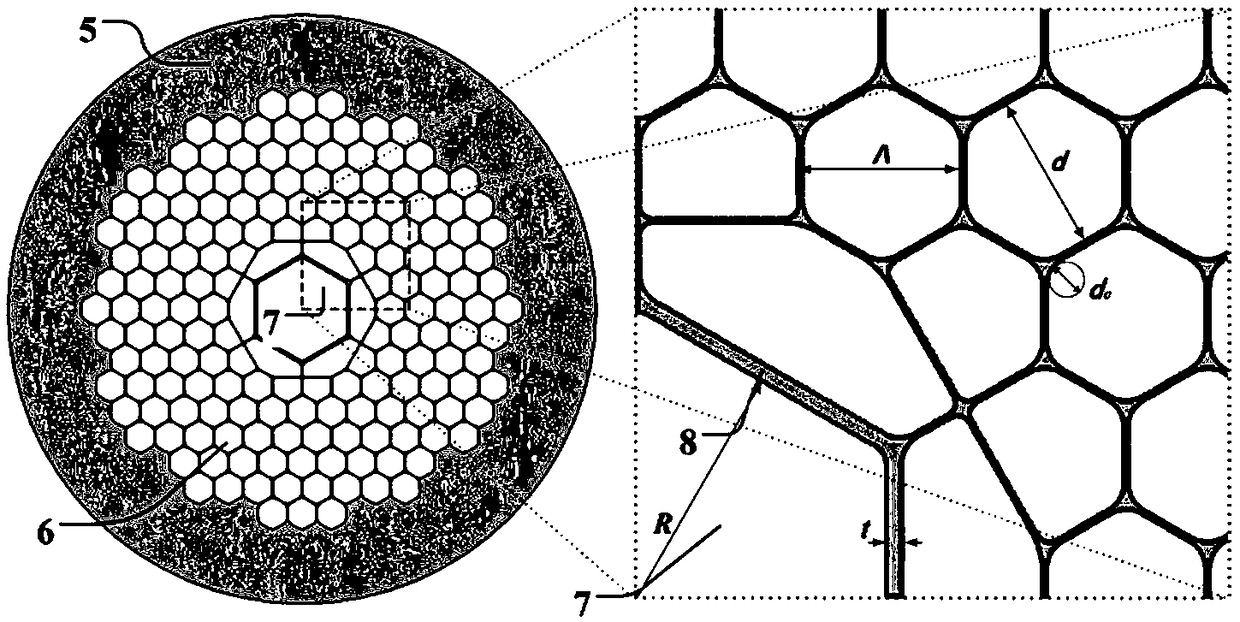

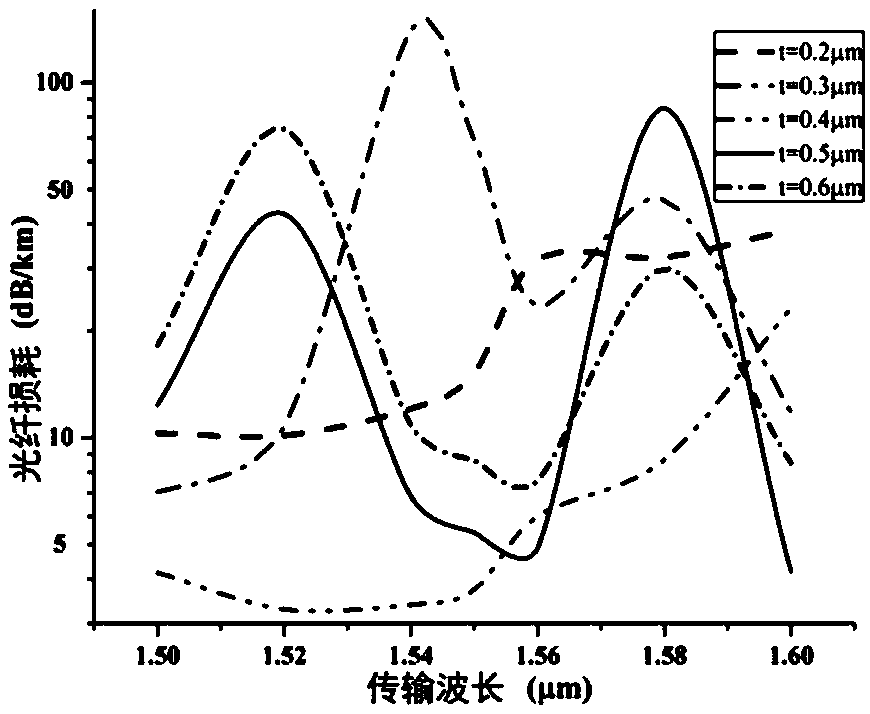

[0025] The present invention provides a hollow-core photonic bandgap fiber based on an isolation anti-resonance layer, such as figure 2 As shown, it includes a quartz cladding 5, an air hole cladding 6, an isolation antiresonance layer 8, and a fiber core 7 from outside to inside, and an isolation antiresonance layer 8 is arranged between the fiber core 7 and the air hole cladding 6, The thickness of the isolation anti-resonance layer 8 is 0.2-0.6 μm, and the material of the isolation anti-resonance layer 8 is quartz glass; the shape of the isolation anti-resonance layer 8 is approximately a regular hexagon.

[0026] The thickness of the isolation anti-resonance layer is preferably 0.4 μm.

[0027] The distance from the center of the fiber core 7 to the air hole cladding 6 is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com