Organic waste gas adsorption-desorption recycling technology and device

A technology of organic waste gas and recovery device, which is applied in gas treatment, membrane technology, and separation of dispersed particles, etc. It can solve the problems of low condensation temperature, inability to discharge directly, and lower utilization rate, so as to reduce investment and operating costs and reduce energy loss , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

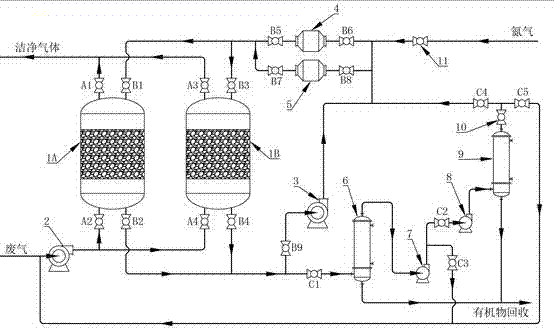

[0028] Embodiment 1: with figure 1 The organic waste gas adsorption-desorption process shown further illustrates the present invention.

[0029] An organic waste gas adsorption-desorption process and device with two adsorbers for primary adsorption, including an adsorption system, a desorption system and a recovery system.

[0030] The adsorption system includes adsorber 1, main fan 2, adsorption valves A1, A2, A3, A4, exhaust gas pipeline and exhaust gas pipeline; the desorption system includes adsorber 1A, 1B, circulation fan 3, heater 4, cooler 5 , desorption valves B1, B2, B3, B4, B5, B6, B7, B8, B9, nitrogen valve 11, circulation pipeline and nitrogen pipeline; recovery system includes vacuum pump 7, compressor 8, primary condenser 6, Secondary condenser 9, recovery valves C1, C2, C3, C4, C5, pressure reducing valve 10, desorption gas pipeline and recovery pipeline.

[0031] The exhaust gas pipeline communicates with the exhaust gas inlets of the adsorbers 1A and 1B, an...

Embodiment 2

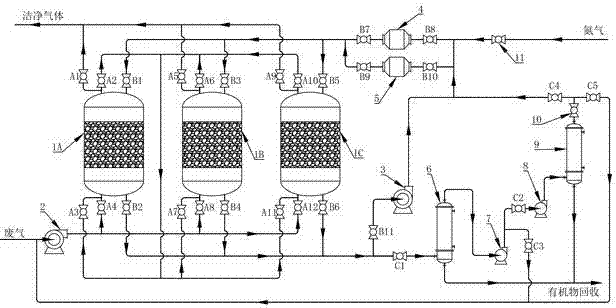

[0046] Embodiment 2: with figure 2 The organic waste gas adsorption-desorption process shown further illustrates the present invention.

[0047] The organic waste gas adsorption-desorption process and device including three adsorbers for secondary adsorption, the process steps are as follows.

[0048] The exhaust gas enters the adsorber 1A from the main fan 2 through the adsorption valve A4. After the organic matter in it is partially adsorbed, the gas enters the adsorber 1B from the exhaust gas outlet through the adsorption valves A2 and A7. It is discharged through the adsorption valve A5. When the adsorber 1A is saturated, the adsorption valves A2, A4, A5, A7 are closed, and the adsorption valves A6, A8, A9, A11 are opened at the same time, so that the exhaust gas enters the adsorber 1B, 1C for adsorption and purification.

[0049] Open the desorption valve B2, the recovery valve C1, and turn on the vacuum pump 7 to evacuate the adsorber 1A, and open the recovery valve C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com