Recycling and regeneration process method for waste automobile power battery anode material

A technology of positive electrode material and power battery, which is applied in the field of recycling and regenerating the positive electrode material of waste automobile power battery, can solve the problem of no uniform standard for industrialized recycling, and achieve the effect of realizing sustainable utilization of resources, reducing energy consumption and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

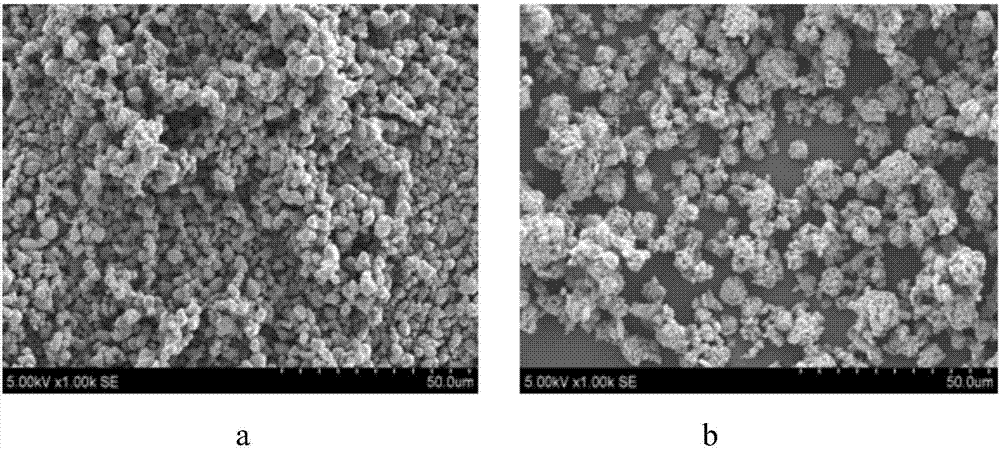

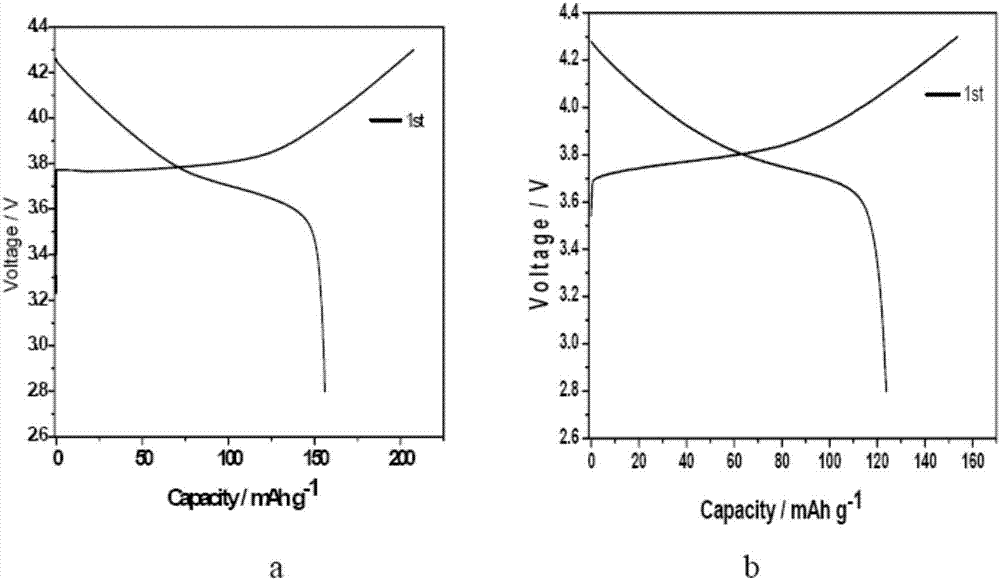

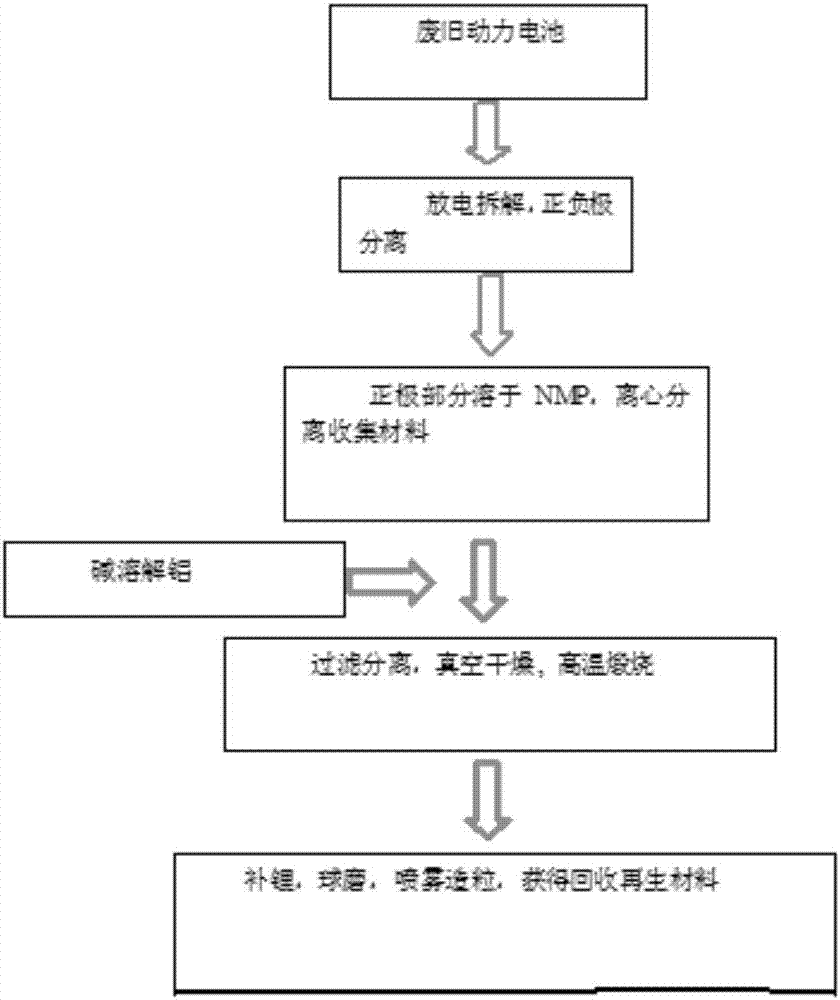

Embodiment 1

[0028] Discharge the battery safely to 2.0V; replace the electrolyte, cut the battery along the top with diagonal pliers, disassemble the battery, separate the removed cells, separate the positive electrode, negative electrode, and diaphragm, and the positive electrode part is to be deal with. Clean the negative electrode and separator in a closed environment and collect them for later use; cut the positive electrode part into 4-9cm 2 Place the small pieces in NMP or deionized water to immerse and ultrasonicate for 5 hours, add a strong base to dissolve the residual aluminum chips, and then carry out vacuum drying after centrifugation. After calcining at 500°C for 2.5 hours, the recycled electrode material was obtained, and lithium supplementation was carried out according to n(Ni+Co+Mn) / nLi=1:1.05~1.1, and NH 3 · H 2 O-NH 4 NO 3 The buffer solution is adjusted to pH=8, and the slurry is made in the ball mill, the inlet temperature is set at 180°C, the outlet temperature i...

Embodiment 2

[0030] Discharge the battery safely to 2.0V; replace the electrolyte, cut the battery along the top with diagonal pliers, disassemble the battery, separate the removed cells, separate the positive electrode, negative electrode, and diaphragm, and the positive electrode part is to be deal with. Clean the negative electrode and separator in a closed environment and collect them for later use; cut the positive electrode part into 4-9cm 2 Place the small pieces in NMP or deionized water to immerse and ultrasonicate for 5 hours, add a strong base to dissolve the residual aluminum chips, and then carry out vacuum drying after centrifugation. After calcining at 500°C for 2.5 hours, the recycled electrode material was obtained, and lithium supplementation was carried out according to n(Ni+Co+Mn) / nLi=1:1.05~1.1, and NH 3 · H 2 O-NH 4 NO 3 The buffer solution is adjusted to pH=8, and the slurry is made in the ball mill, the inlet temperature is set at 180°C, the outlet temperature i...

Embodiment 3

[0032] Discharge the battery safely to 2.0V; replace the electrolyte, cut the battery along the top with diagonal pliers, disassemble the battery, separate the removed cells, separate the positive electrode, negative electrode, and diaphragm, and the positive electrode part is to be deal with. Clean the negative electrode and separator in a closed environment and collect them for later use; cut the positive electrode part into 4-9cm 2 Place the small pieces in NMP or deionized water to immerse and ultrasonicate for 5 hours, add a strong base to dissolve the residual aluminum chips, and then carry out vacuum drying after centrifugation. After calcining at 500°C for 2.5 hours, the recycled electrode material was obtained, and lithium supplementation was carried out according to n(Ni+Co+Mn) / nLi=1:1.05~1.1, and NH 3 · H 2 O-NH 4 NO 3 The buffer solution is adjusted to pH = 8, and the slurry is made in the ball mill. The inlet temperature is set at 180°C, the outlet temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com