Method for recycling polyester waste by normal-pressure alcoholysis

A technology of atmospheric pressure alcohol and waste, applied in the fields of recycling technology, plastic recycling, chemical instruments and methods, etc., can solve the problems of ethylene glycol difficult to recycle, difficult to recycle, environmental pollution, etc., to reduce production costs and equipment requirements The effect of low and shortened process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

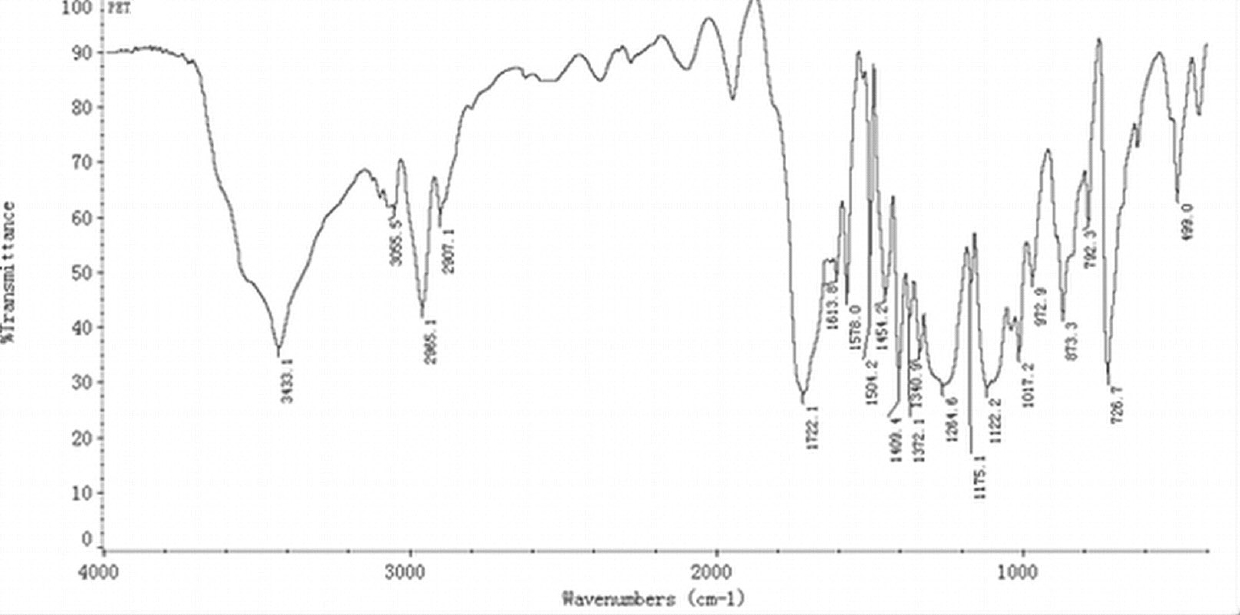

[0027] Polyester is formed by esterification and polycondensation of terephthalic acid and ethylene glycol. The monomers or low molecular polymers obtained by reverse reaction alcoholysis under the action of catalyst and ethylene glycol can be used as unsaturated polyesters. Raw materials, then add saturated or unsaturated dibasic acid and ethylene glycol, and undergo esterification and polycondensation to obtain unsaturated polyester resin.

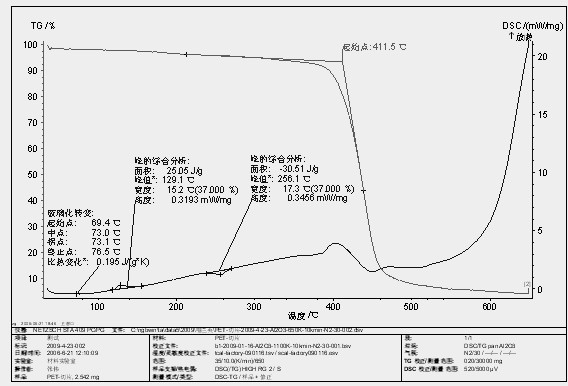

[0028] The invention uses polyester (PET) waste (including its products) as raw material, ethylene glycol (EG) as degradation agent, zinc acetate (Zn(OAc) 2 ) as a catalyst for alcoholysis, and the alcoholysis is carried out under normal pressure.

[0029] The specific steps are:

[0030] 1) Material preparation - weighing polyester waste m 1 , and prepare materials according to the mass ratio of polyester waste, eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com