Fine treatment process for building solid waste

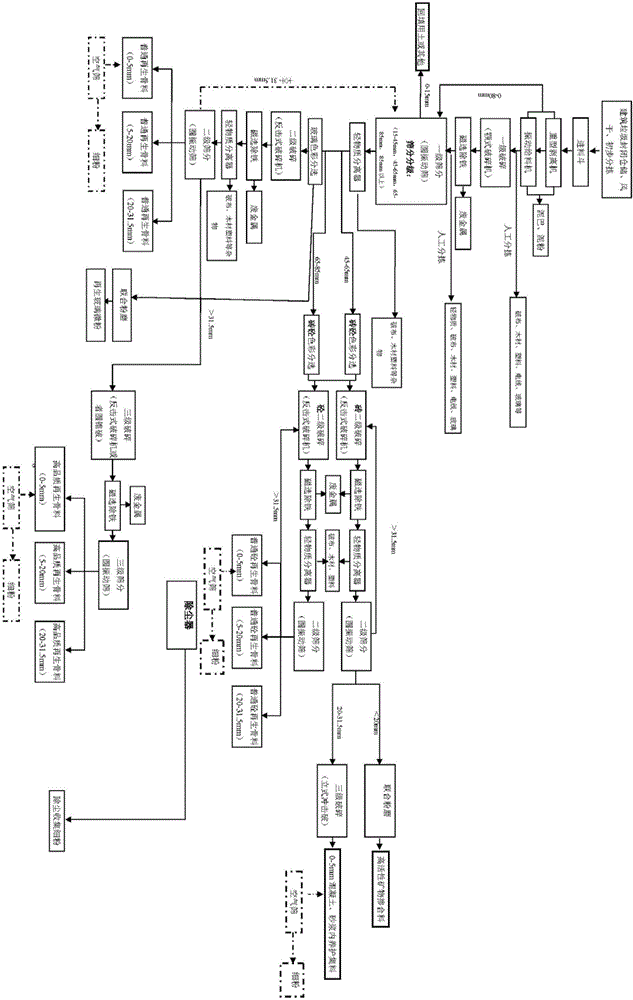

A treatment process and construction technology, applied in the field of high-quality construction solid waste treatment process, can solve the problems of unstable product quality, lack of systematic impurity removal means, low treatment efficiency, etc., and achieve no clogging of crushers and screening equipment, crushing Efficient screening and air selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-quality construction solid waste treatment process, comprising the following steps:

[0034] (1) Air-dry the construction solid waste in a closed yard, try to ensure that the moisture content of the construction solid waste is kept below 10%; then carry out preliminary manual sorting, and sort out rags, plastics, glass, wires, and steel bars as much as possible , wood, etc., to reduce the pressure for subsequent sorting;

[0035] (2) Transport the remaining construction solid waste after sorting in step (1) to a heavy-duty stripping screen to remove mixed mud, and then transport it to a vibrating feeder. The construction solid waste with a particle size of 0-80mm is directly After entering the first-level screening, the remaining parts are firstly manually sorted out of rags, plastics, glass, wires, wood and other materials, and then enter the first-level jaw crushing, so that the particle size is basically kept below 100-150mm. Then carry out magnetic separatio...

Embodiment 2

[0046] A high-quality construction solid waste treatment process can be refined into the following steps:

[0047] Step 1: Pre-treat the construction solid waste, air-dry it in a closed storage yard, and perform preliminary manual sorting. The sorted plastic, glass, wire, steel bar, wood, etc. enter step 17. The building solid waste after the initial manual sorting waste into step 2;

[0048] Step 2: The manually sorted construction solid waste is fed into the hopper, transported to the heavy-duty stripping sieve to screen out mixed mud; Solid waste directly enters step 6, while construction solid waste with a particle size above 80mm enters step 3;

[0049] Step 3: Carry out first-level manual sorting of construction solid waste with a particle size above 80mm, sort out rags, wood, plastics, wires, etc. and enter step 17, and the construction solid waste of this first-level manual sorting enters step 4;

[0050] Step 4: The first-level artificially sorted construction solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com