Method for recycling silicon powder from silicon slice cut waste mortar

A technology for cutting silicon wafers and cutting waste sand, which is applied in the direction of chemical instruments and methods, silicon, silicon compounds, etc., can solve the problems of recycling process, product purity is not high, solid-liquid separation is difficult, etc., to achieve strong applicability and save Alkali consumption, the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The silicon powder recovery test is being carried out by Jiangsu Creed Recycling Technology Co., Ltd.

[0036] The company used to only recycle polyethylene glycol and silicon carbide, and all the silicon powder in the cutting waste mortar was discarded. Combining the method described in the present invention with the company's previous production process, the front production process was adjusted, and the primary solid-liquid separation process was adjusted to secondary separation; at the same time, some key equipment and its auxiliary equipment were newly added or modified, Including precision filters, membrane separation equipment, flotation tanks, vacuum drying equipment, etc., a 600L / hour silicon powder recovery test production line has been built.

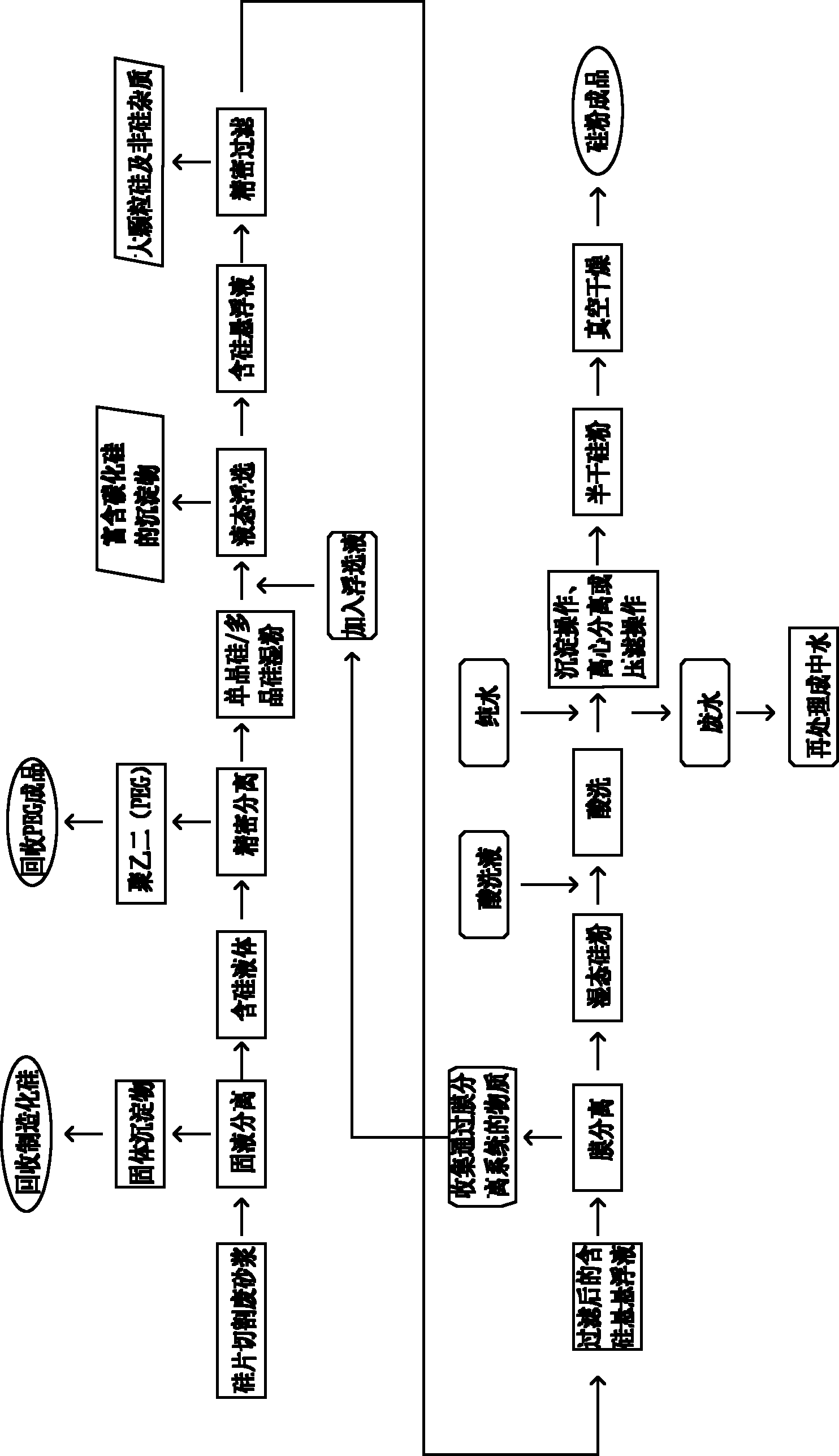

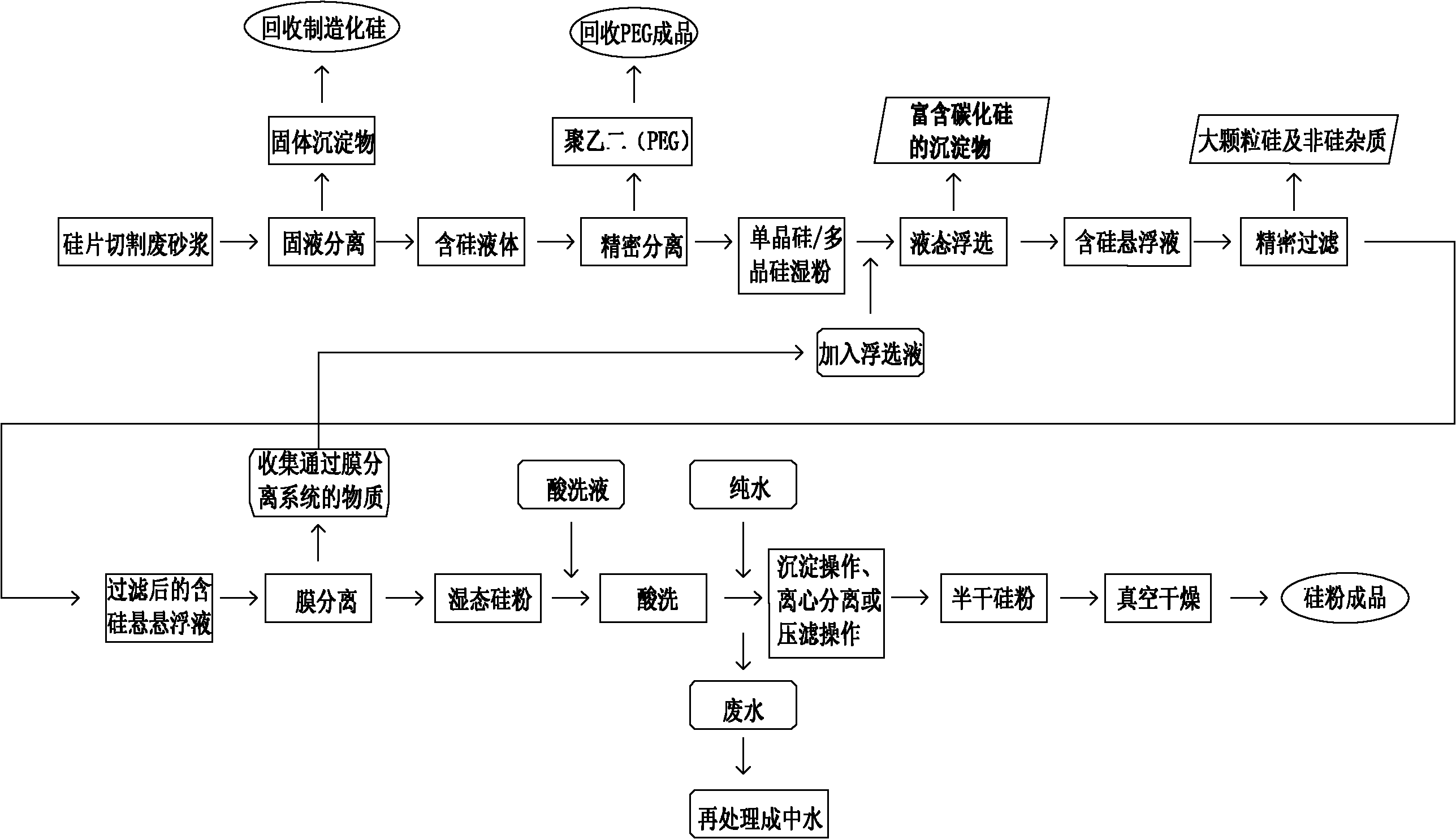

[0037] The process flow chart of the test is as follows figure 1 As shown, the specific situation is as follows:

[0038] The main components of the cutting waste mortar used in the test are: by weight percentage, 45...

Embodiment 2

[0048] Experiment of recovering polysilicon powder from the silicon-containing waste residue discarded by the online recovery system of Zhenjiang Dacheng New Energy Company.

[0049] The process flow chart of the test is as follows figure 1 As shown, the specific situation is as follows:

[0050] The main components of the silicon-containing waste residue used for the test are: by weight percentage, 24% polyethylene glycol solution, 16% silicon carbide, 57.6% polysilicon powder, and the rest are impurities.

[0051] Take 500kg of silicon-containing waste residue, add 200kg of recycled cutting fluid (from Jiangsu Kelide Recycling Technology Co., Ltd.) and 200kg of pure water as diluents, and mix thoroughly to form cutting waste mortar, which is continuously fed The method is injected into the centrifuge for solid-liquid separation, and the centrifugal force is 1200g; 100kg of solid precipitate (containing about 20% liquid content) and 800kg of silicon-containing liquid are obt...

Embodiment 3

[0059] The silicon powder recovery test was carried out in the pilot plant of Saipu (Wuxi) Membrane Technology Development Co., Ltd.

[0060] In order to systematically study the comprehensive utilization technology of silicon wafer cutting waste mortar, Saipu Company built a pilot plant. The scale of the pilot plant is 100kg / hour waste mortar treatment capacity, and it has both offline and online waste mortar recycling system features. Using the method of the present invention, the company obtained 200kg of waste mortar that had been placed for many years and was ready to be discarded from Hebei Fengqiang Company to carry out a silicon powder recovery test to explore whether the process of the present invention is suitable for the recycling of old stock waste mortar.

[0061] The details of the test are as follows:

[0062] The main components of the cutting waste mortar used in the test are: by weight percentage, 43% polyethylene glycol solution, 45% silicon carbide, 5% pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com