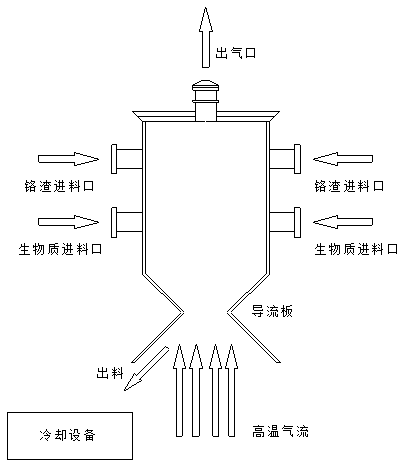

Fluidized bed type of harmless chromium slag pyrolysis process

A fluidized bed, harmless technology, applied in the field of environmental protection, can solve the problems of reduced reducing gas concentration, reduced reduction efficiency, weak reducing atmosphere, etc., and achieves reduction of cooling time, easy secondary utilization, and shortened reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0026] 1. Crush the chromium slag, collect particles with a particle size of 0.5-3mm, and transport them to the pyrolysis furnace from the top chromium slag feed port. After passing through the fluidized layer, it reacts with the pyrolysis gas, and Cr(VI) is reduced. At the same time, the pyrolysis residual carbon adheres to the surface of the chromium slag during the fluidization process to protect the reduced Cr(III) in the chromium slag from secondary oxidation. The chromium slag finally flows out from the discharge port, and is discharged after being cooled by water to below 200°C;

[0027] 2. Biomass enters the fluidized bed pyrolysis furnace from the lower side of the chromium slag feed port, melts and pyrolyzes rapidly and distributes on the surface of chromium slag particles, releasing a large amount of pyrolysis gas at the same time. Control the mass ratio of biomass to chromium slag: biomass: chromium slag=0.7:1;

[0028] 3. In the reduction combustion furnace, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com