Thermoplastic elastomer for nylon material secondary injection adhering

A thermoplastic elastomer, secondary injection bonding technology, applied in the field of thermoplastic elastomers, can solve the problems of unsatisfactory product hand feeling, long molding cooling time, high injection temperature, etc., to facilitate industrial production, good hand feeling, and reduce compounding components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

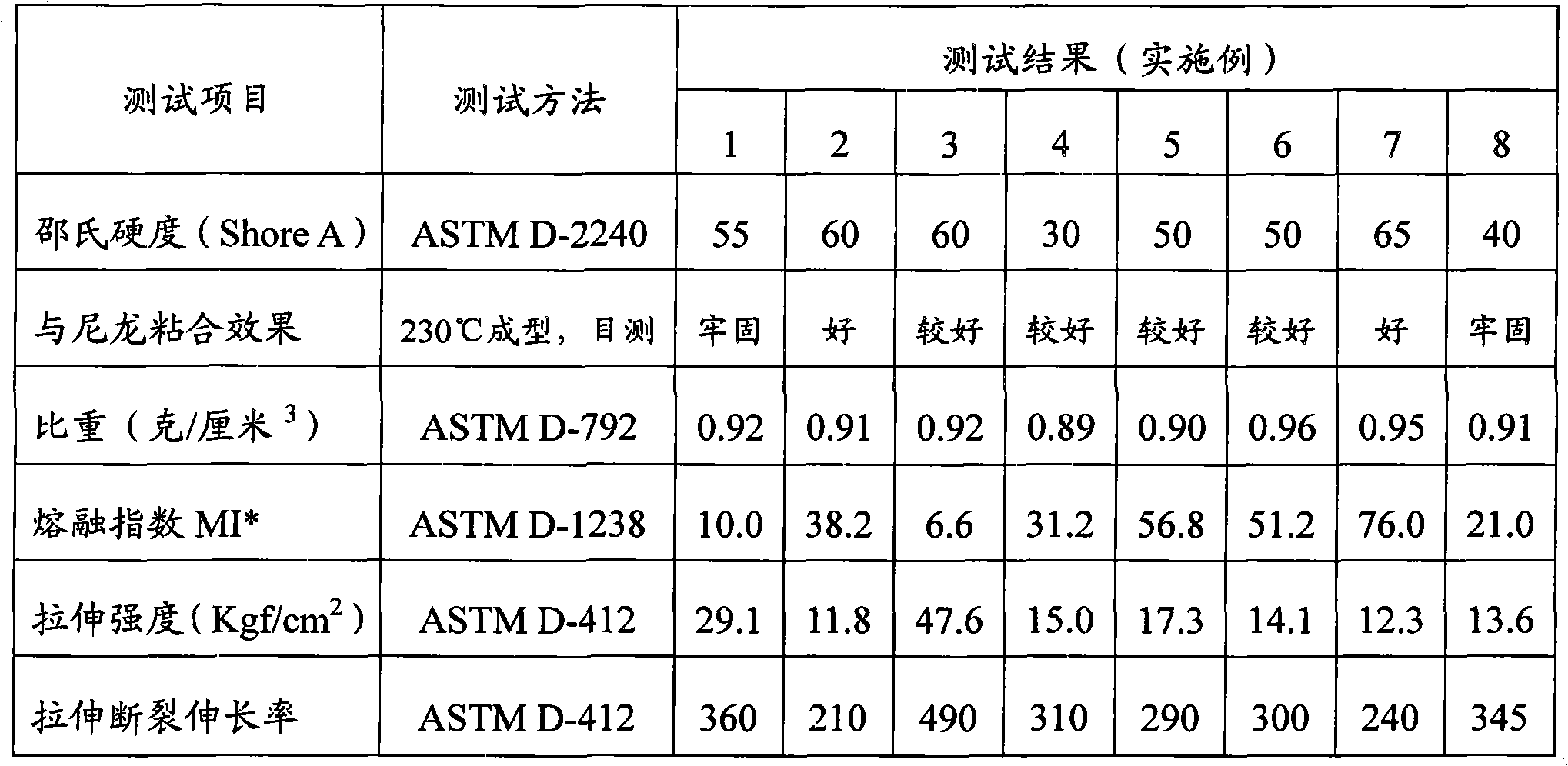

Examples

Embodiment Construction

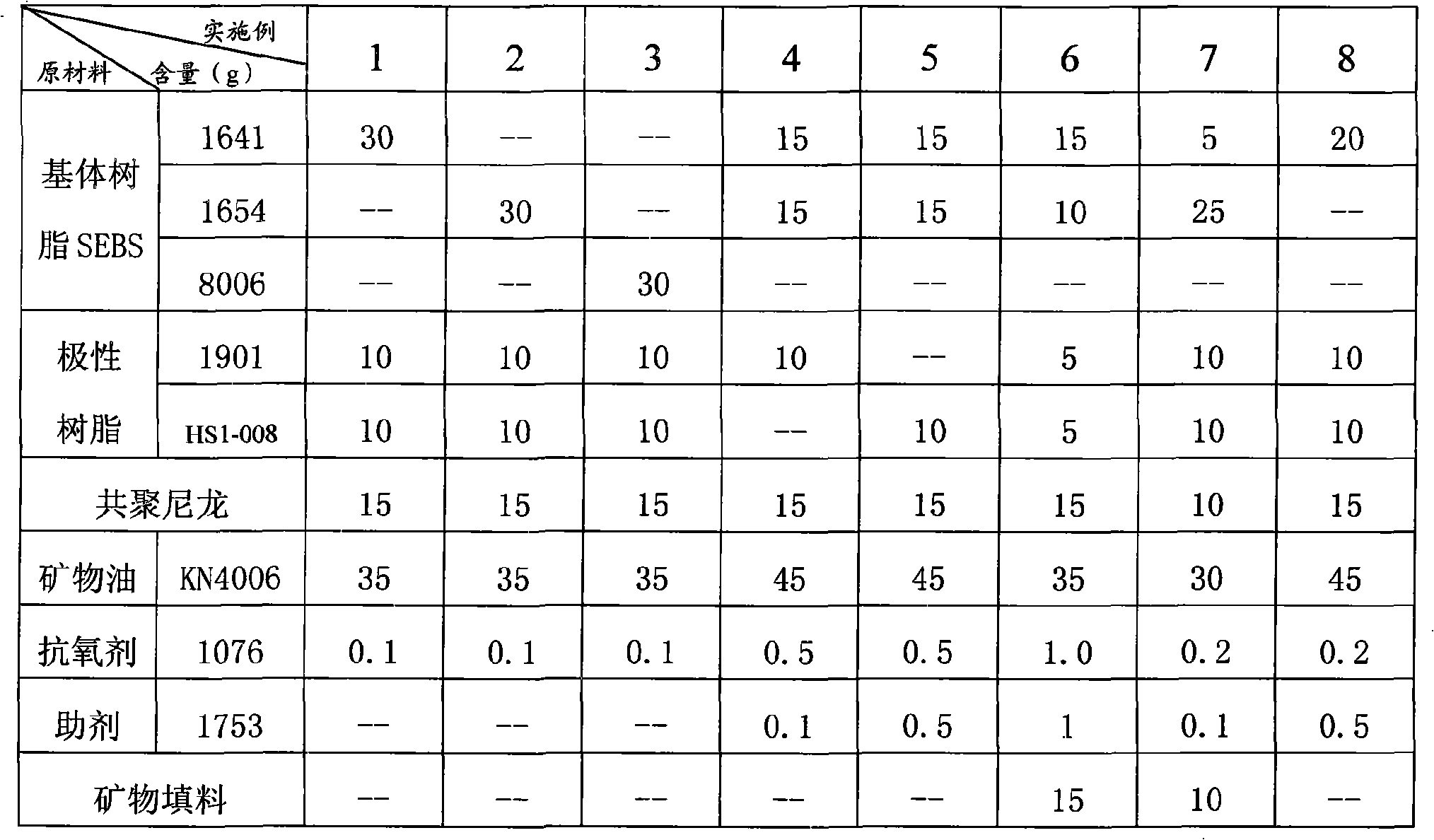

[0022] 1. Raw material ratio

[0023]

[0024] Among the above raw materials, polar resin 1901 and HS1-008 can be replaced by other SEBS-g-MAH or EPDM-g-MAH, POE-g-MAH, PP-g-MAH of the same type;

[0025] Mineral oil KN4006 can be replaced by other saturated linear paraffin oil or naphthenic oil with a flash point higher than 200°C, such as 500N of Ssangyong Company of South Korea;

[0026] Antioxidant 1076 can be replaced by other similar antioxidant 1010, antioxidant 168;

[0027] The mineral filler is one or a mixture of calcium carbonate, talcum powder, gypsum powder, asbestos powder, clay, barium sulfate, mica powder, kaolin;

[0028] The auxiliary agent 1753 can be replaced by other appropriate amount of fatty acid, fatty acid amide, polysilicone.

[0029] 2. Extrusion processing

[0030] Take the raw material components according to the above-mentioned proportions, mix the base resin SEBS and mineral oil fully and evenly,

[0031] Then add polar resin, ternary co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com