Polyurethane foam plastic handle and manufacturing method thereof

A technology of foamed plastics and polyurethane, applied in the direction of coating, etc., to achieve the effect of adapting to temperature changes, high friction coefficient, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the handle according to the embodiment of the present invention will be described in detail.

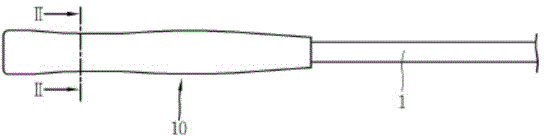

[0028] Such as figure 1 as shown, figure 1 It is a state figure which provided the handle in the handle part of a fishing rod in one embodiment of this invention. The handle 10 is pressed or pasted on the end of the fishing rod 1 . Certainly, the handle 10 can also be arranged on other positions than the middle part, the end and the middle part of the fishing rod 1 . In addition, the handle 10 can also be arranged on multiple positions of the fishing rod 1 . The portion of the handle 10 thus provided is collectively referred to as a handle.

[0029] In addition, in this embodiment, the handle 10 may be provided on the handle part of the fishing rod, or the handle 10 may be provided on the handle part of the hiking stick.

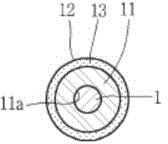

[0030] figure 2 is icon figure 1 Cross-section - diagram.

[0031] Such as figure 2 As shown, the handle 10 is composed of a polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com