A kind of high-temperature-resistant high-entropy alloy nbmotawv thin film and preparation method thereof

A high-entropy alloy, high-temperature-resistant technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of high cost, high stress of bulk material, high preparation temperature, and achieve smooth surface, resistance to resistance. The effect of large value change range and good resistivity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

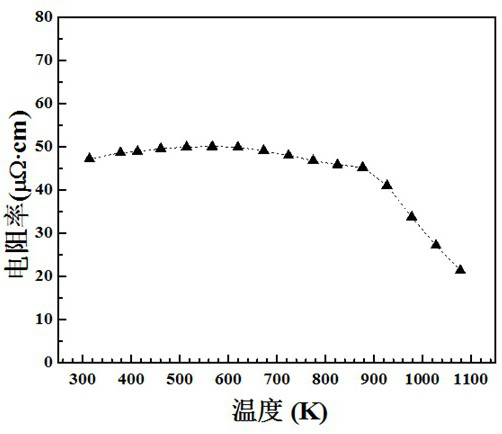

[0022] Embodiment 1: Preparation of NbMoTaWV by radio frequency magnetron sputtering method 0.62 film

[0023] (1) Preparation of alloy sputtering target

[0024] Preparation of alloy target: according to Nb:Mo:Ta:W atomic percentage 1:1:1:1, the mass of each metal component is weighed and smelted into a target with a purity of 99.9%; The main sputtering area of the elemental target is prepared into a five-element combined alloy target;

[0025] (2) Preparation of high-temperature resistant NbMoTaWV high-entropy alloy thin films

[0026] Cleaning the substrate: select a single crystal Si substrate, ultrasonically clean it with alcohol, ethanol and deionized water in sequence (10 minutes each), and then put the single crystal silicon wafer in a 5% hydrofluoric acid solution for 2 to 3 minutes, Rinse with deionized water and rinse with N 2 Blow dry and put in vacuum chamber;

[0027] Film preparation by magnetron sputtering: vacuum to 3.0×10 -4 Below Pa, fill high-purity...

Embodiment 2

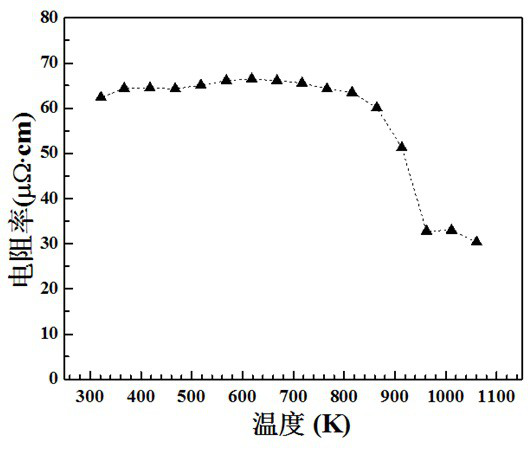

[0032] Example 2: Preparation of NbMoTaW by magnetron sputtering 1.19 V 1.51 film

[0033] The preparation process is the same as in Example 1, only the number of V sheets is increased, and the film characterization method is the same as in Example 1. The composition of the obtained film is NbMoTaWV 1.51 , the film thickness is 460nm, the hardness is 11.20Gpa, and the resistivity at room temperature is 80.05 . figure 2 The resistivity-temperature curve under this composition is shown, and the resistivity can also remain constant from room temperature to 600°C, showing the excellent high temperature resistance of the film. The high-temperature-resistant high-entropy alloy NbMoTaWV thin film can be used for microelectronic device materials, high-temperature-resistant materials and high-hardness and wear-resistant materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com