Single welding and series welding integrity device of solar cell slices

A technology for solar cells and equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency and high fragmentation rate, and achieve reduced scrapping, low fragmentation rate, and precise length control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

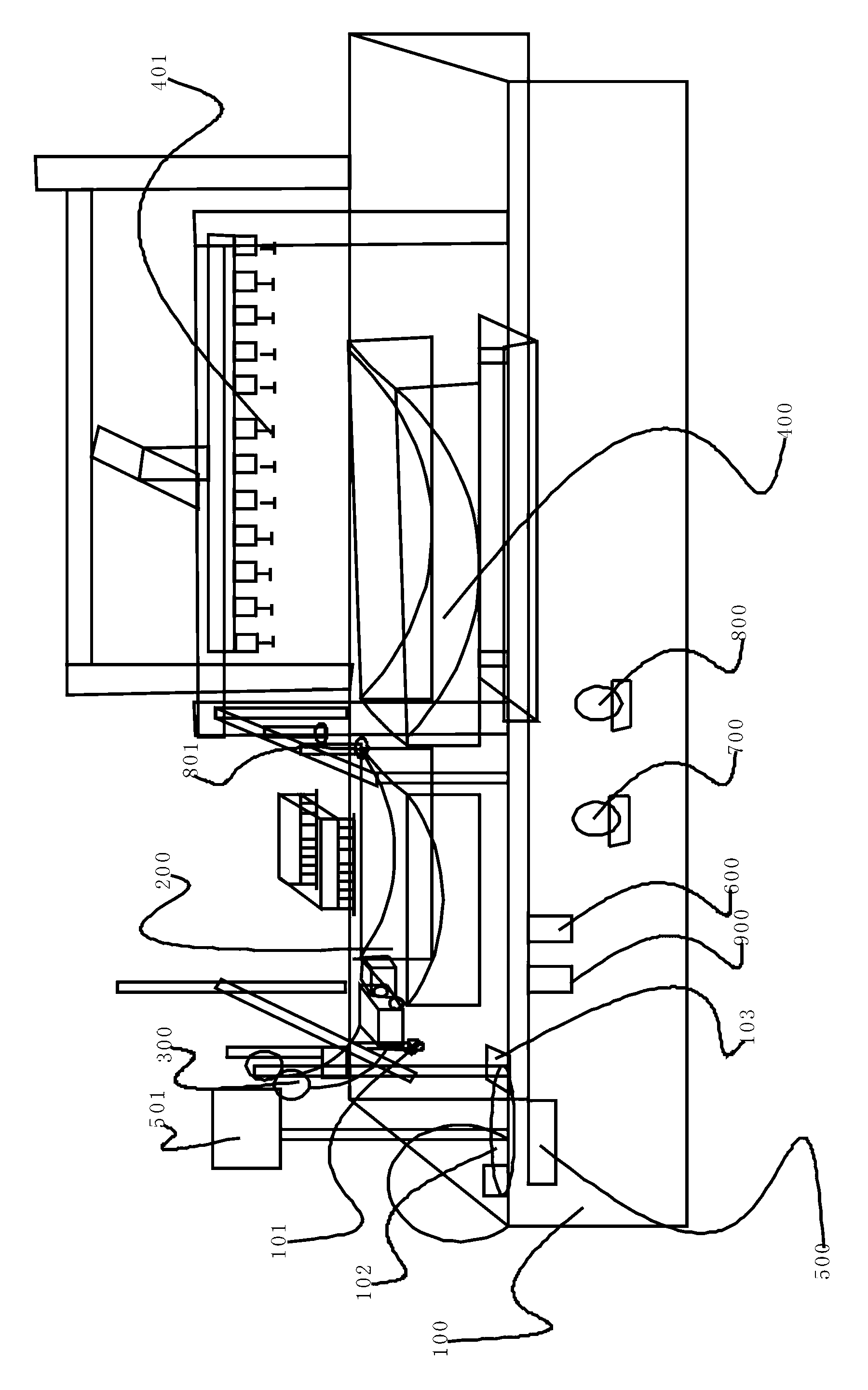

[0018] to combine figure 1 , which describes the specific implementation of the present invention in detail, but does not limit the claims in any way.

[0019] In the structure of the single-welding and series-welding integrated equipment of the solar cells of the present invention, an equipment frame 100 is included, and the equipment frame is provided with: a feeding mechanism, and the feeding mechanism includes a feeding mechanism for feeding materials. Conveyor belt 102, a feeding suction cup 101 is provided above the feeding conveyor belt 102, and a cell integrity detection platform 103 is also provided on the equipment frame 100; a transmission and positioning mechanism, the transmission and positioning mechanism includes a conveyor belt 200 for Drive the transmission servo motor and position sensor of the conveyor belt; the welding and temperature control mechanism, the welding and temperature control mechanism includes a welding ribbon supply device 300, a flux su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com