Ultra-light modified thermoplastic rubber TE material

A thermoplastic rubber and thermoplastic styrene-butadiene technology, used in the field of modified thermoplastic rubber TE materials, can solve the problems of complex production process, low production capacity, poor wear resistance, etc., and achieve effective use of waste resources, light weight, and outsole tortuosity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Put the raw materials with the weight percentage of the following components into the internal mixer to produce TE pellets, then pour the TE pellets into the raw material barrel, heat the pellets of different colors in stages according to the color requirements, and inject them into the container in stages The finished product is pulled out after the final cooling on the machine of the good mold.

[0010] Thermoplastic elastomer TPE (model 1475) 23%, block copolymer SEBS (model 3000S) composed of styrene (S)-ethylene (E) and butene (B)-styrene (S) 5%, ethylene (E) and vinyl acetate (VA) EVA (model 7350) 20%, ethylene octene copolymer POE8%, thermoplastic styrene-butadiene rubber SBS 23%, poly-α-methylstyrene resin ATL2%, softening oil ( white oil) 9%, zinc oxide ZnO 1%, anti-purple agent 2%, antioxidant 2%, ultra-light foaming powder (model A-9) 1%, low-temperature expansion agent 1%, white foam 1% , Titanium dioxide 2%.

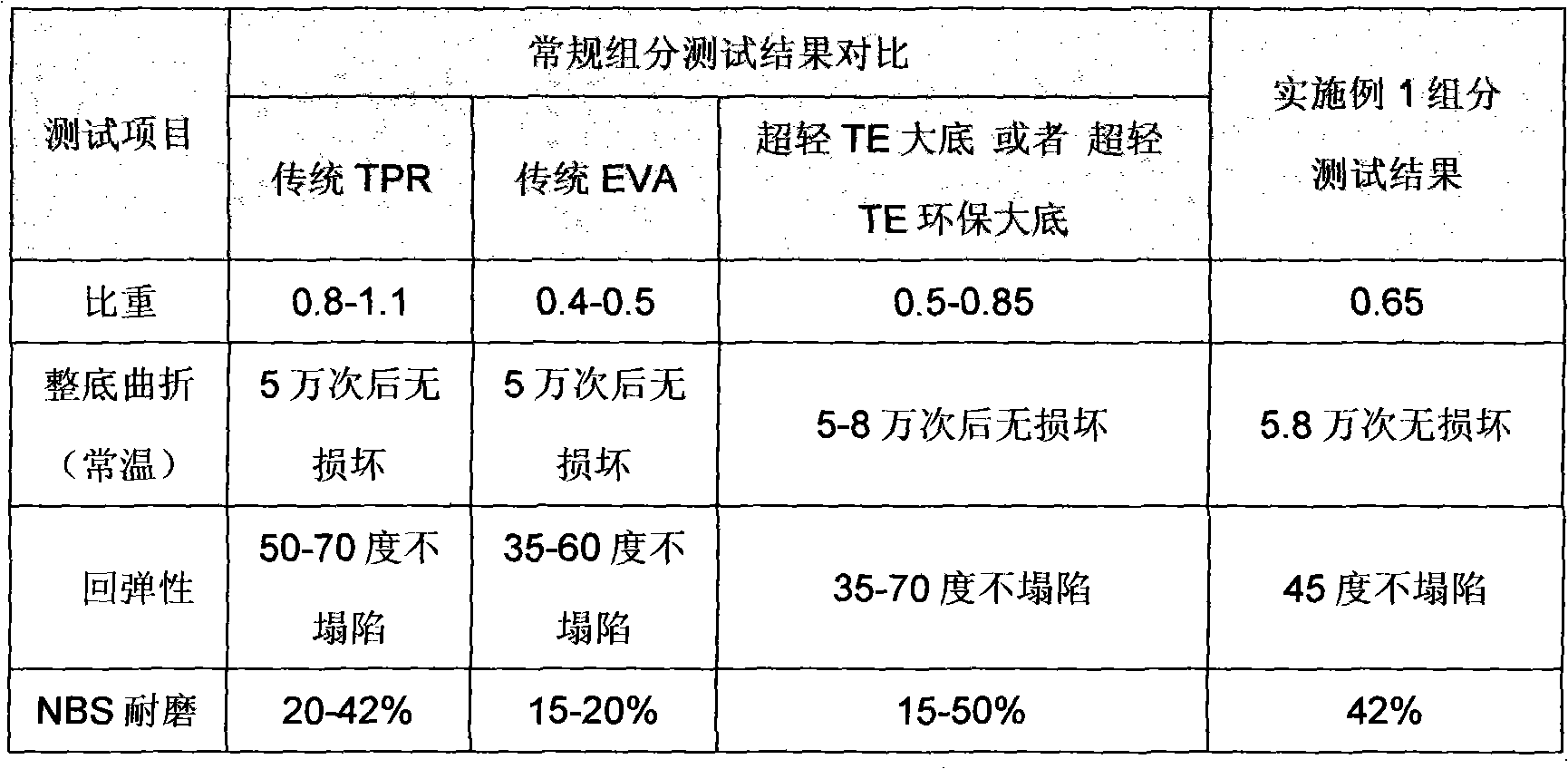

[0011] The test result contrast of this embod...

Embodiment 2

[0015] Put the raw materials with the weight percentage of the following components into the internal mixer to produce TE pellets, then pour the TE pellets into the raw material barrel, heat the pellets of different colors in stages according to the color requirements, and inject them into the container in stages The finished product is pulled out after the final cooling on the machine of the good mold.

[0016] Thermoplastic elastomer TPE (model 1475) 17%, block copolymer SEBS (model 3000S) composed of styrene (S)-ethylene (E) and butene (B)-styrene (S) 5%, ethylene (E) and vinyl acetate (VA) EVA (model 7350) 25%, ethylene octene copolymer POE 15%, thermoplastic styrene-butadiene rubber SBS 15%, poly-α methyl styrene resin ATL 2%, softening oil ( white oil) 5%, zinc oxide ZnO 1%, anti-purple agent 2%, antioxidant 2%, ultra-light foaming powder (model A-9) 3%, low-temperature expansion agent 3%, white foam 3% , Titanium dioxide 2%.

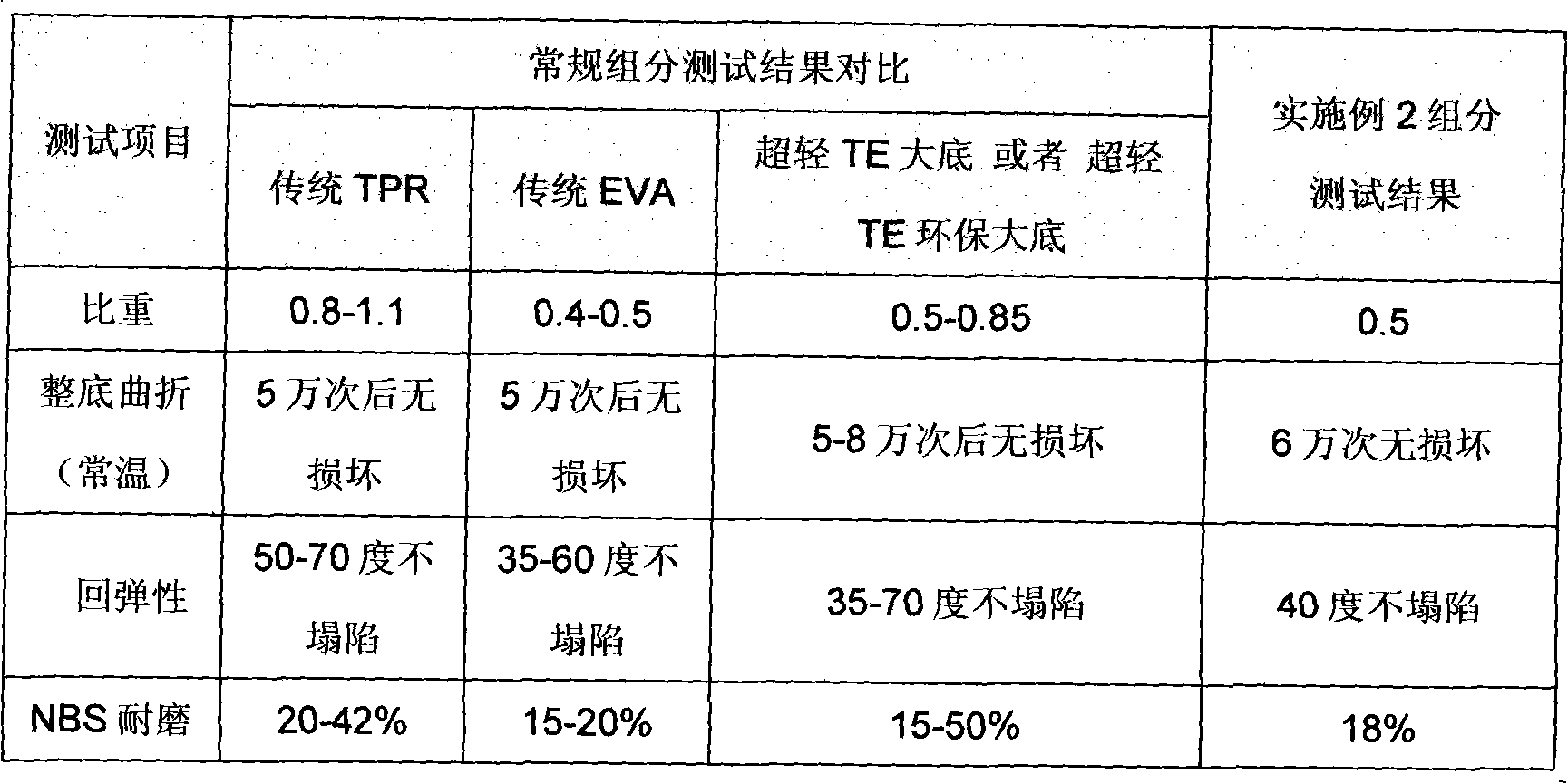

[0017] The test result contrast of this e...

Embodiment 3

[0021] Put the raw materials with the weight percentage of the following components into the internal mixer to produce TE pellets, then pour the TE pellets into the raw material barrel, heat the pellets of different colors in stages according to the color requirements, and inject them into the container in stages The finished product is pulled out after the final cooling on the machine of the good mold.

[0022]Thermoplastic elastomer TPE (model 1475) 28%, block copolymer SEBS (model 3000S) composed of styrene (S)-ethylene (E) and butene (B)-styrene (S) 5%, ethylene (E) and vinyl acetate (VA) EVA (model 7350) 20%, ethylene octene copolymer POE6%, thermoplastic styrene-butadiene rubber SBS 14%, poly-α-methylstyrene resin ATL2%, softening oil ( white oil) 15%, zinc oxide ZnO 1%, anti-purple agent 2%, antioxidant 2%, titanium dioxide 2%, ultra-light foaming powder (model A-9) 1%, low-temperature expansion agent 1%, White foam 1%.

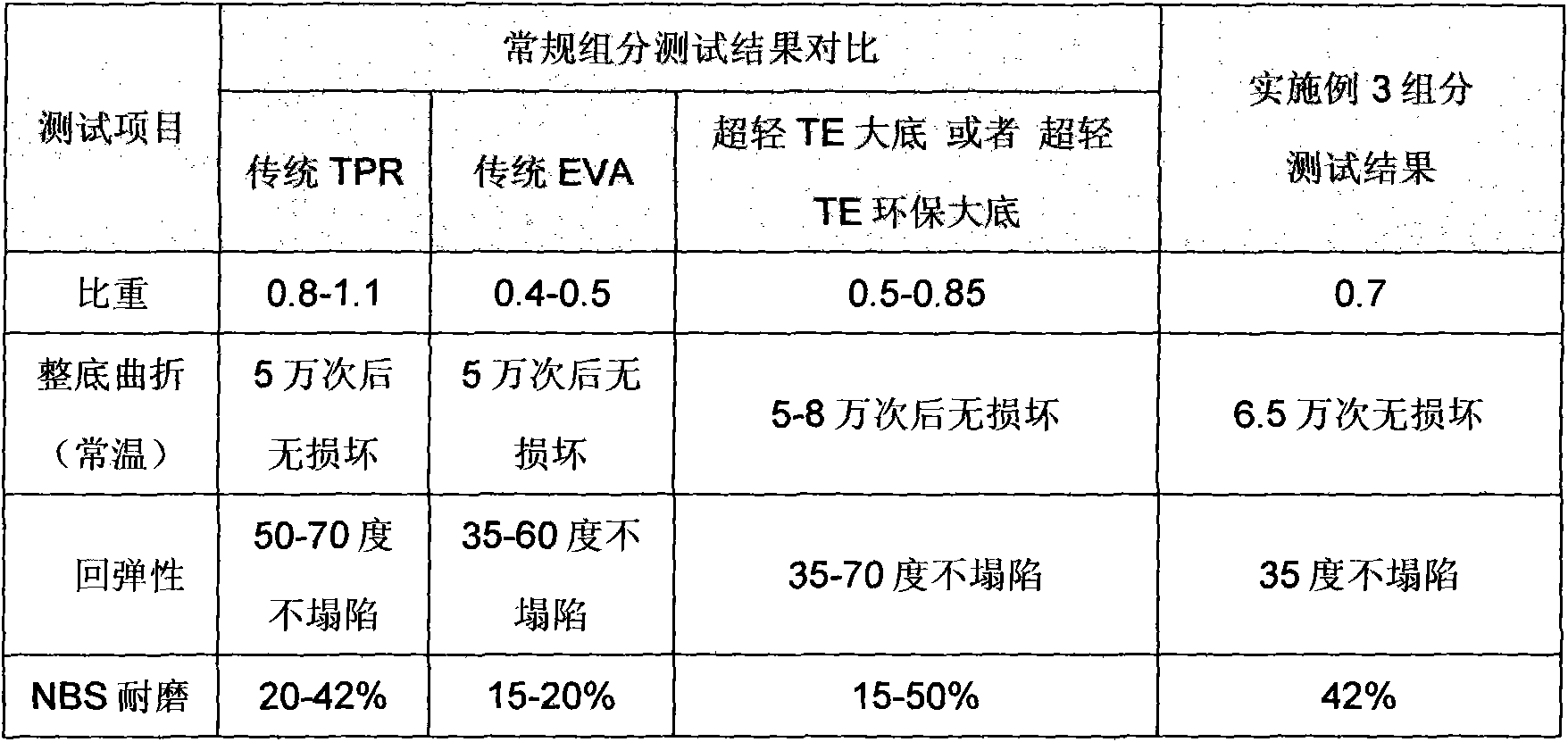

[0023] The test result contrast of this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com