Composite welding scheme between dissimilar metal materials

A technology of composite welding and dissimilar materials, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

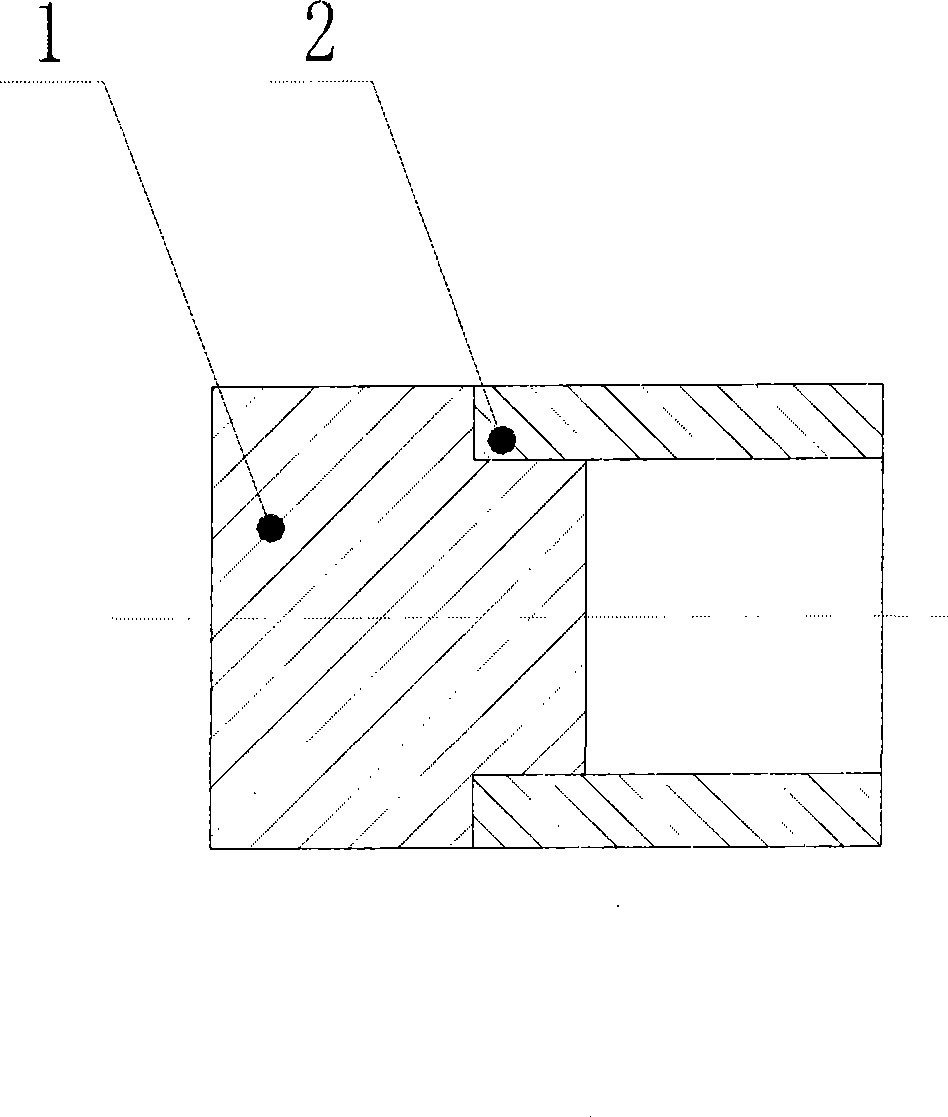

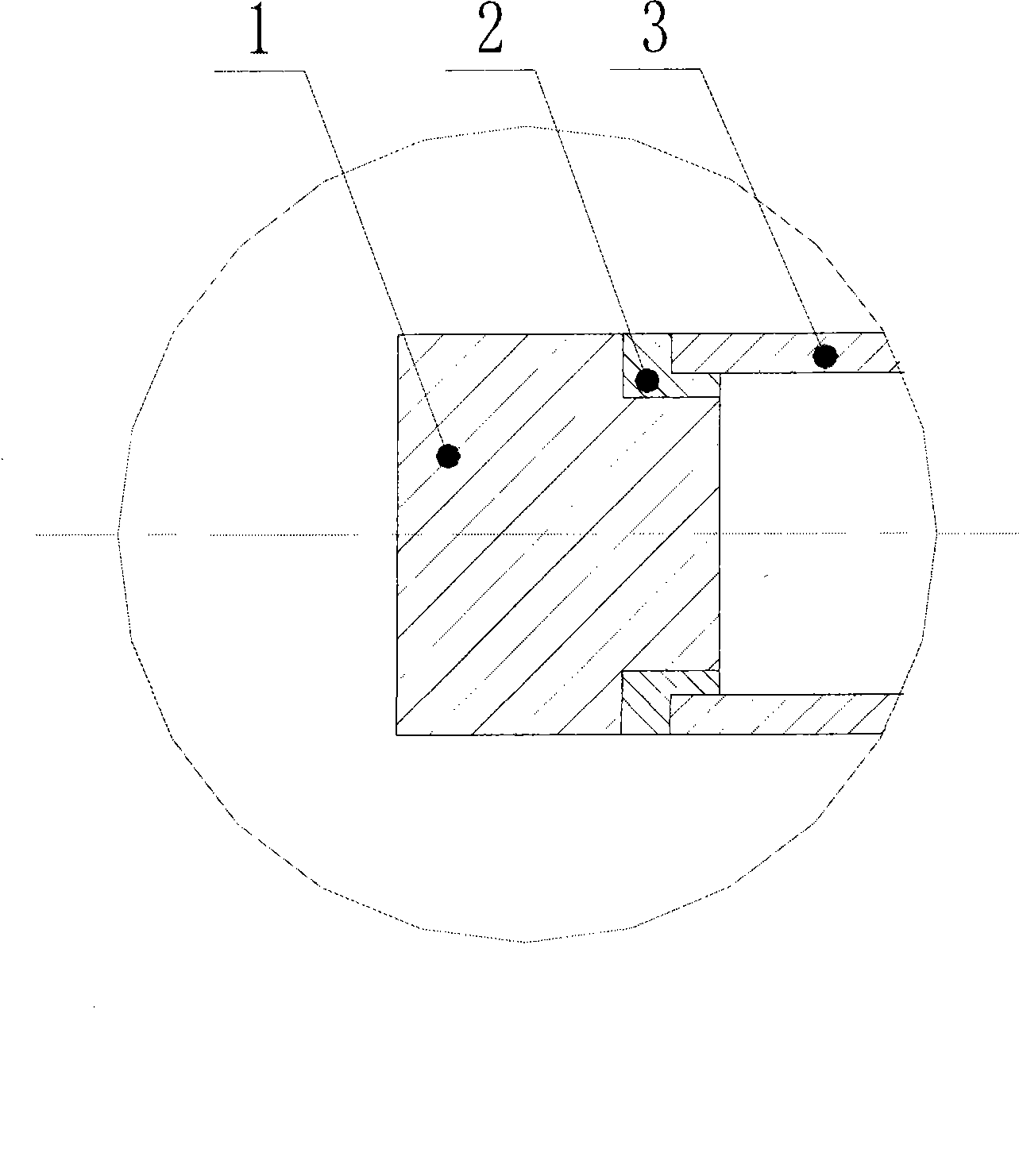

[0010] Such as figure 2 As shown, the present invention proposes a composite welding scheme for dissimilar materials between the cold finger of the expander and the cold cap of the Stirling refrigerator, and it relates to the cold cap of the expander in the Stirling refrigerator 1, welding transition Ring 2 and cold finger 3, the positional relationship of the three after welding is that the welded transition ring 2 is set on the expander cold cap 1, the welded transition ring 2 is stepped, and the expander cold finger 3 is a thin-walled tube. Set on the welding transition 2 ring. The cold finger 3 of the expander in the Stirling refrigerator is made of stainless steel, and the cold cap 1 is made of oxygen-free copper. Due to their different materials, the weldability of the two is poor. Therefore, the cold cap 1 and the welded transition ring 2 involved in the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com