Design method for inertia pipe type pulse pipe cold finger optimally matched with linear compressor

A technology of linear compressors, design methods, applied in compressors, refrigerators, refrigeration and liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

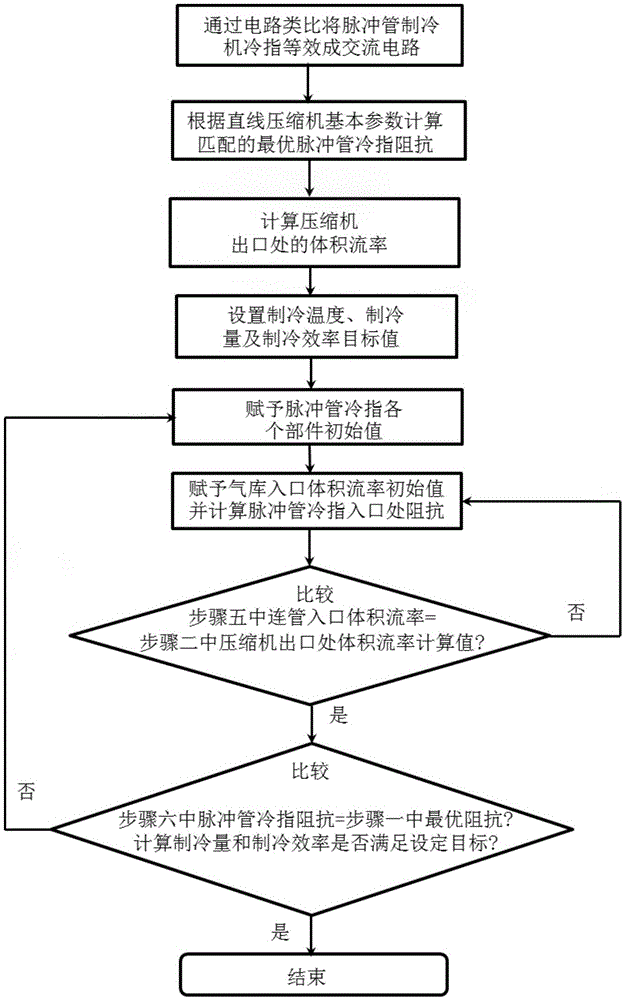

[0064] figure 1 It is a flow chart of the cold finger design method of the invented inertial tube type pulse tube refrigerator that can realize the optimal match with the linear compressor;

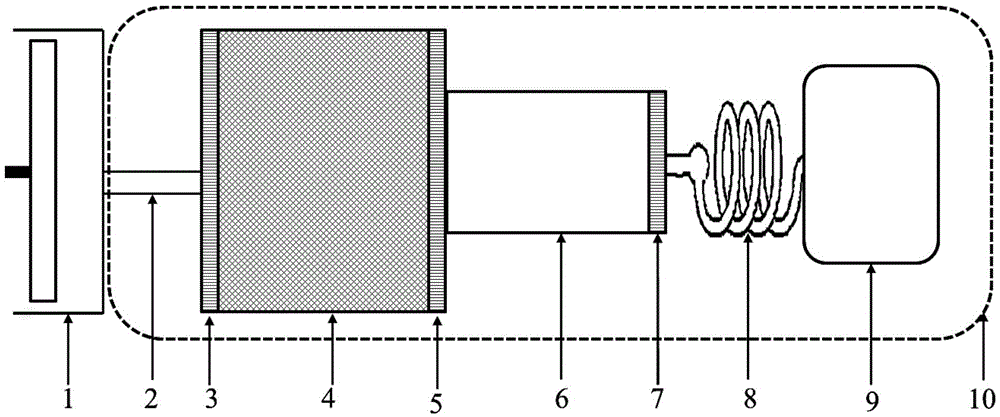

[0065] figure 2 It is a structural schematic diagram of an inertial tube type high frequency pulse tube refrigerator.

[0066] The design method includes the following steps:

[0067] Step 1: The inertial tube type high frequency pulse tube refrigerator includes a linear compressor 1, a connecting tube 2, an after-stage cooler 3, a regenerator 4, a cold end heat exchanger 5, a pulse tube 6, and a hot end heat exchanger 7, Inertia tube 8, gas storehouse 9; connecting pipe 2, after-stage cooler 3, regenerator 4, cold end heat exchanger 5, pulse tube 6, hot end heat exchanger 7, inertial tube 8 and air store 9 The pulse tube cold finger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com