Liquid nitrogen horizontal refrigeration device for testing infrared detector Dewar assembly and design method thereof

A technology for testing infrared detectors and components, used in measuring devices, radiation pyrometry, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

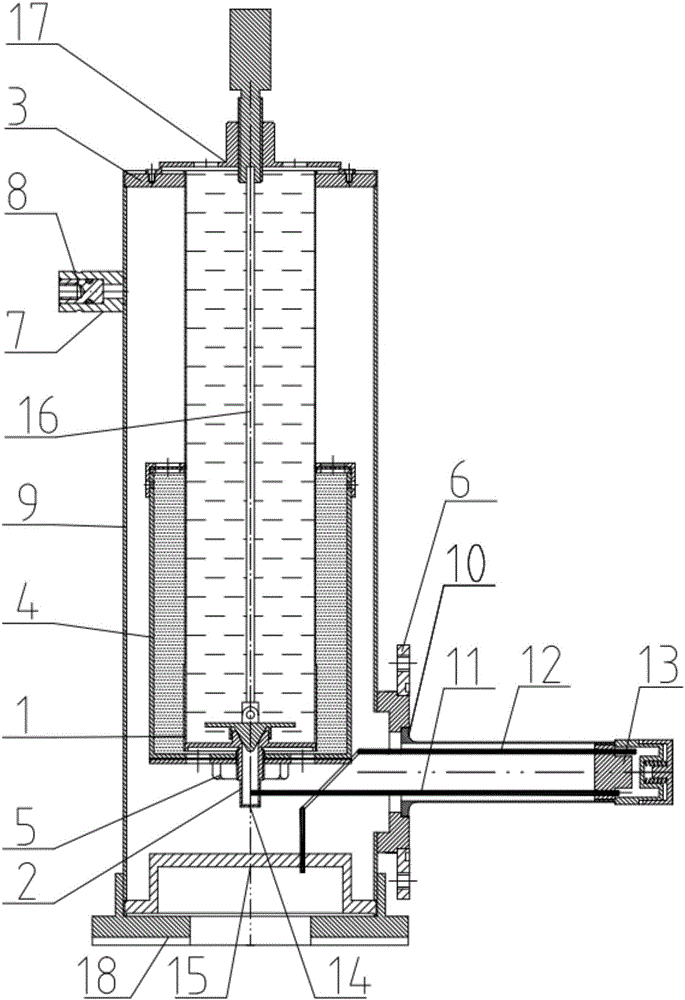

[0060] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing in embodiment:

[0061] This embodiment is to cool down the Dewar assembly of a 512×512 infrared detection device, the heat capacity is 900 joules, the heat load of the Dewar assembly is 600mw during the test operation, and the cooling time for the Dewar is required to be greater than 30 minutes

[0062] One, design result of the present invention is as follows

[0063] ①Design the total amount of liquid nitrogen required according to the heat capacity, heat leakage and cooling time of the dewar assembly of the separate infrared detector

[0064] The heat capacity of the split-type infrared detector Dewar assembly is Q1=900 (unit: Joule); after the heat leakage of Dewar and the Joule heat of the detector work, it is W=0.6 (unit: watt); the cooling time is T=1800 (unit : second); The latent heat of every gram of liquid nitrogen is Q2=99.74 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com