Full metal sealed EMCCD camera refrigeration dewar

An all-metal, camera technology, applied in the field of photoelectric detection, can solve the problems of large leakage rate and insufficient vacuum validity period, and achieve the effect of low leakage rate and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

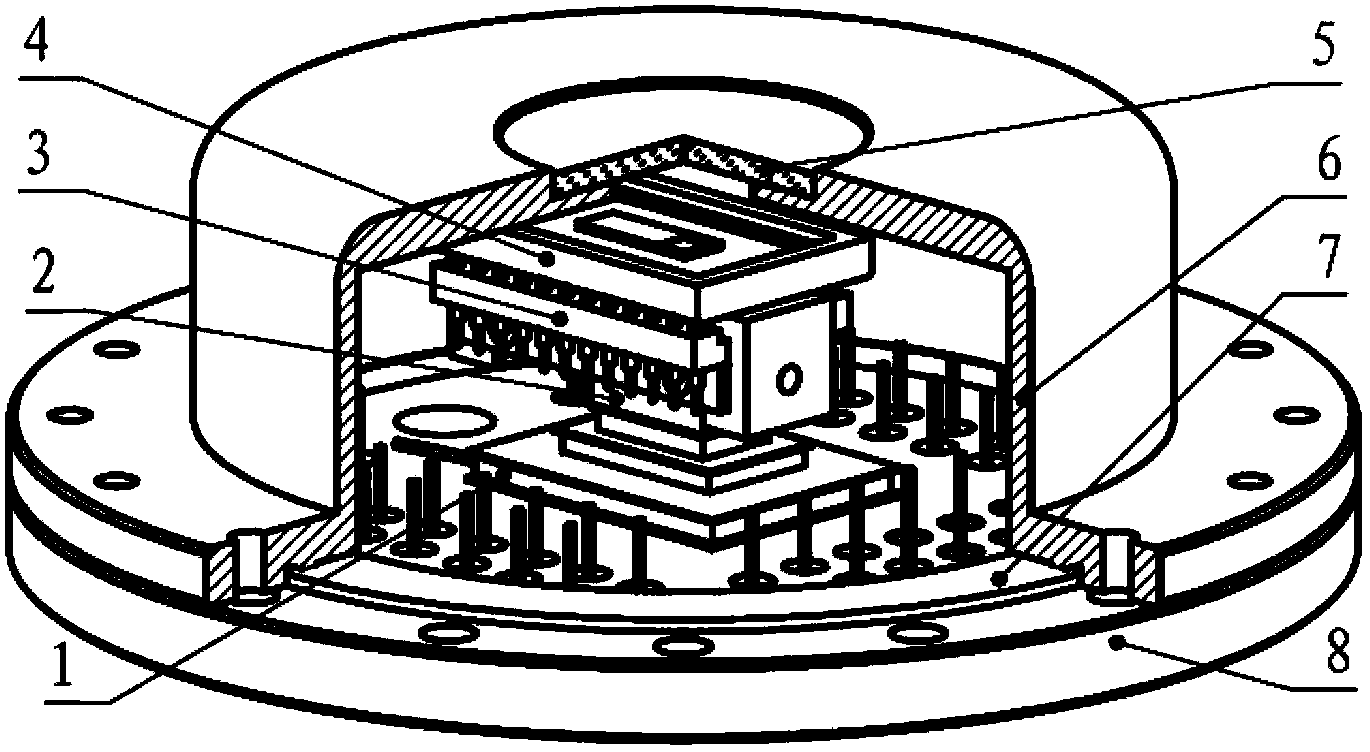

[0010] like figure 1 As shown, the all-metal sealed EMCCD camera cooling Dewar of the present invention is composed of a thermoelectric cooler (TEC) 1, a cold finger 2, a CCD socket 3, an EMCCD 4, a window 5, a casing 6, a copper sealing ring 7, and a base 8. The window 5, the shell 6 and the base 8 form a vacuum chamber. TEC1, cold finger 2, EMCCD4, etc. are placed in a vacuum chamber.

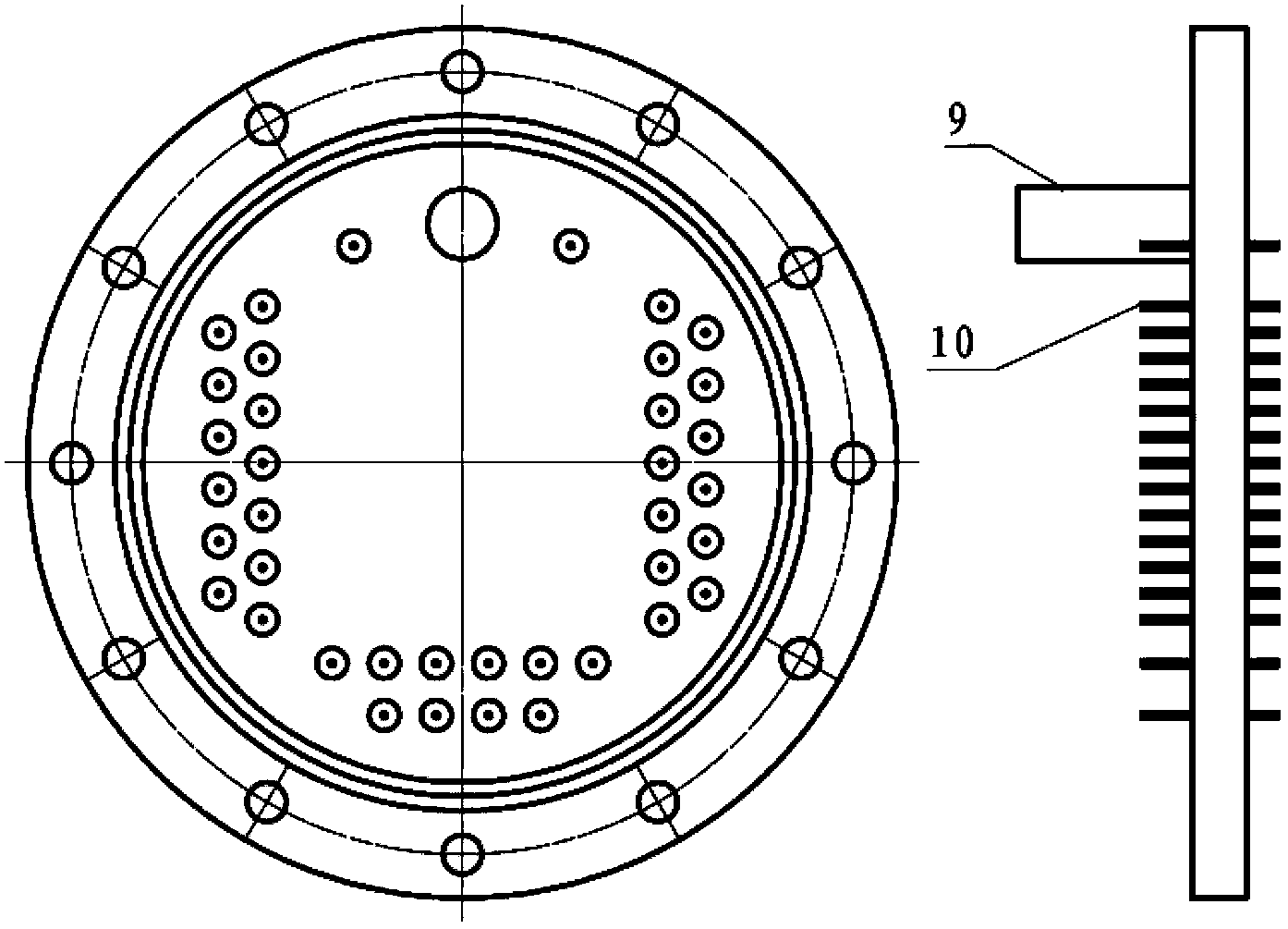

[0011] Firstly, the base 8 should be processed and the welding of the window 5 and the shell 6 should be completed. like figure 2 , the main body of the base 8 is copper, and the electrodes 10 are welded through ceramics. The electrode 10 is a communication channel between the inside of the chamber and the outside. At the same time, an oxygen-free copper tube 9 is also welded on the base 8 . After the base processing is completed, leak detection is required to detect the leakage rate of the weld. The window 5 and the housing 6 are welded by anodic welding. After the welding is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com