Refrigeration infrared detector

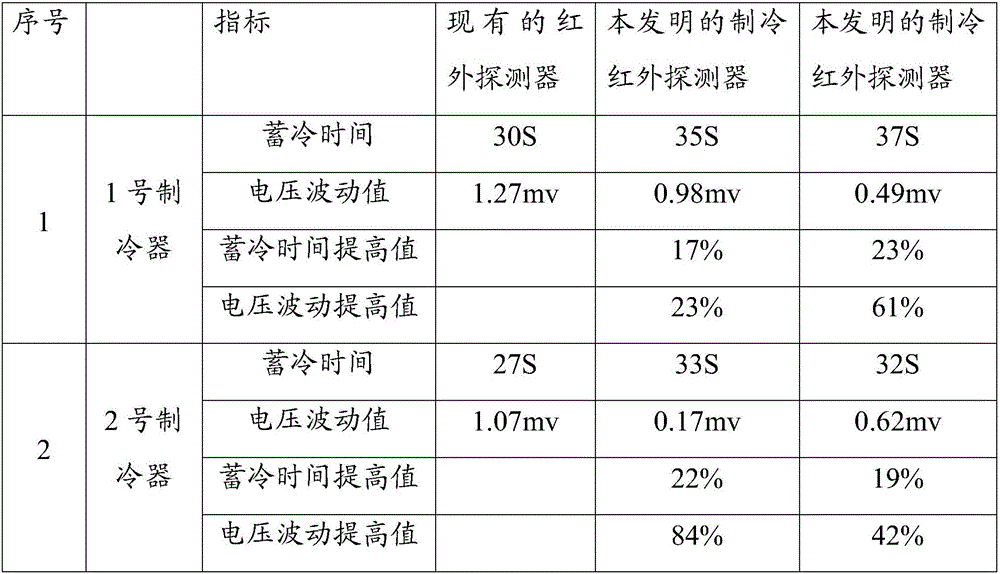

A technology of infrared detectors and refrigerators, which is applied in the field of infrared detection, can solve the problems that the cold storage time cannot be improved, and the temperature fluctuation of the detector can achieve the effect of enhancing the stability of temperature control and prolonging the cold storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

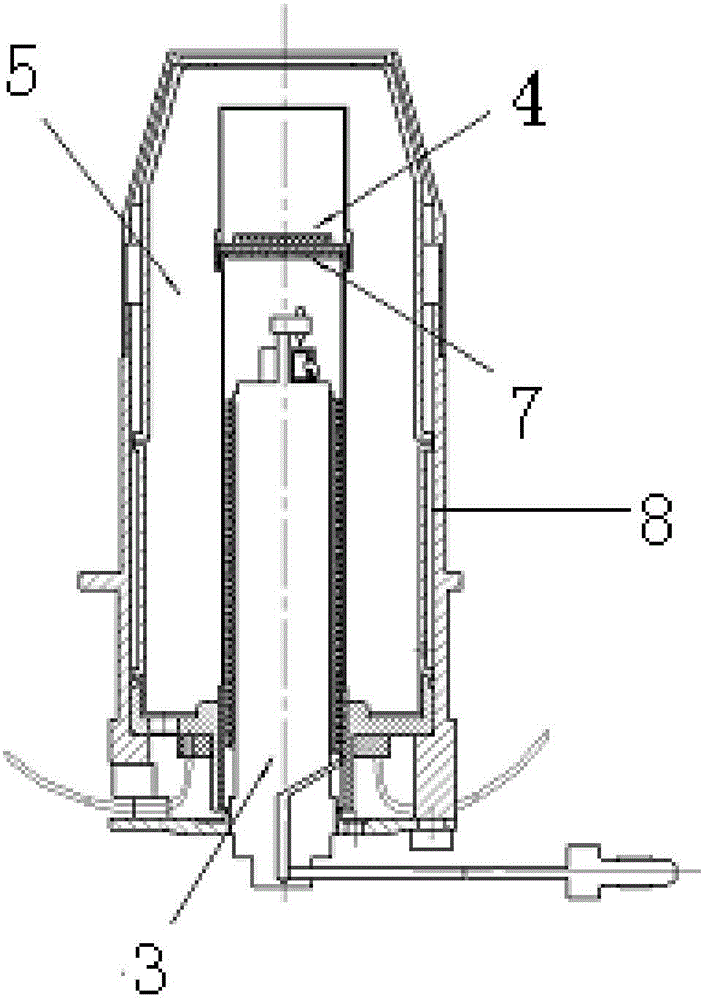

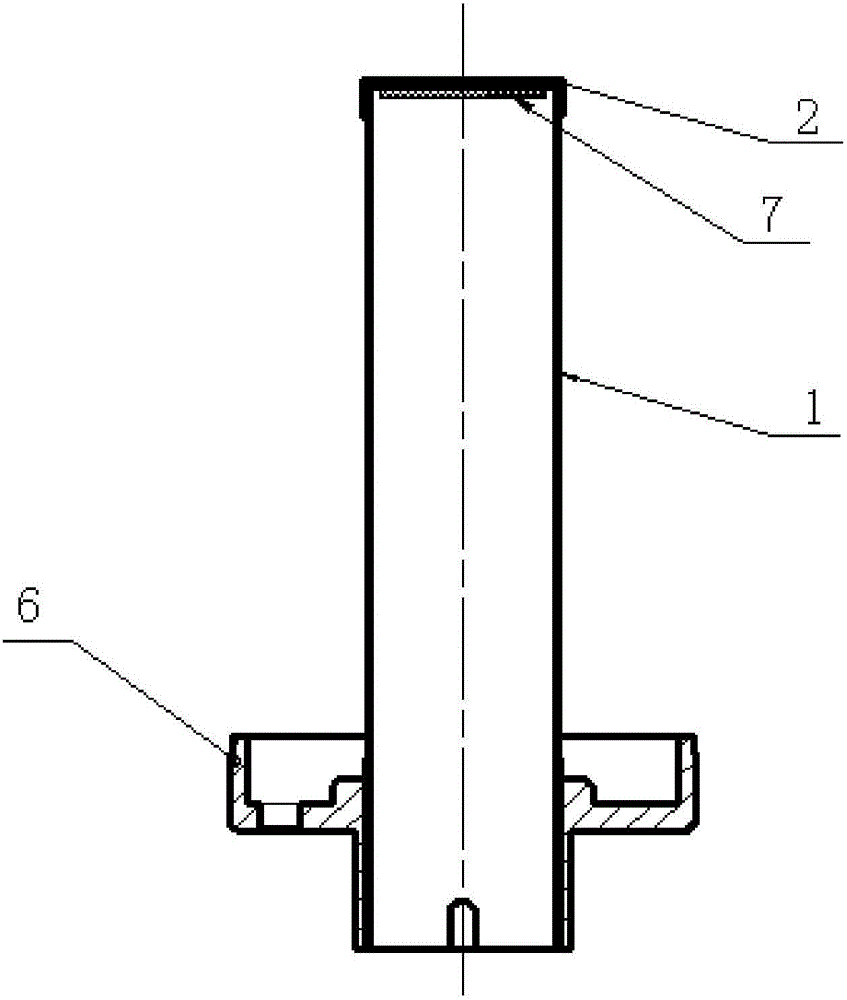

Method used

Image

Examples

Embodiment approach

[0039] ●Use tweezers to place the solder sheet on the back of the cold head, then place the cold storage wire mesh on the solder, and then place the brazing tooling in the stem.

[0040] Put the parts to be welded into the constant temperature zone of the furnace, and ensure that there are no foreign objects on the furnace table and furnace door, close the furnace door, start the mechanical pump, open the side pumping valve to vacuum the furnace chamber, and wait until the vacuum gauge shows that the vacuum degree is lower than After 10Pa, close the side pumping valve, open the front stage valve and main pumping valve of the molecular pump, start the molecular pump, and when the vacuum degree is better than 1x10E-3Pa, start the heating program, heat to 810°C-835°C, keep warm at 0- 1min, with the furnace cooling down to below 100°C, turn off the valve and the pump unit in turn, and when the temperature shows below 40°C, open the gas filling valve, pour nitrogen into the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com