Vacuum residue discharging system

A technology of vacuum and vacuum generating devices, which is applied in the direction of negative pressure pumps, machines/engines, pump components, etc., which can solve the problems of pumping device wear and tear, and achieve the effects of long life, excellent economy, and long maintenance cycle intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

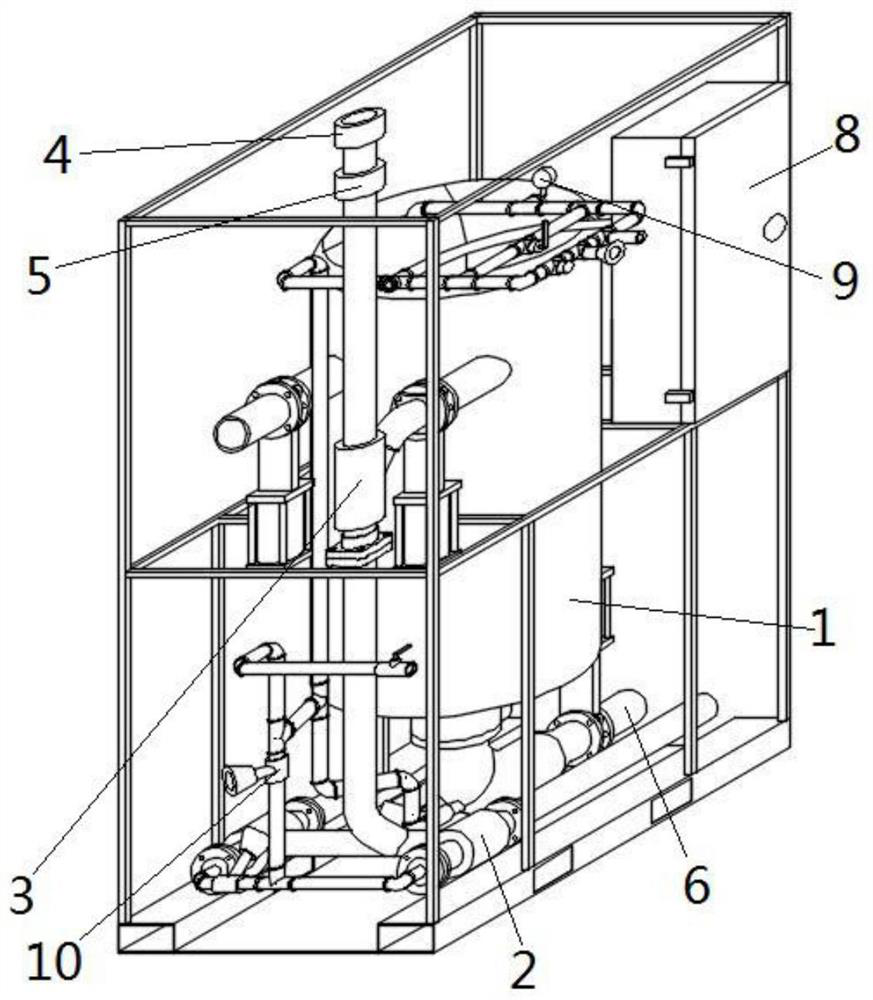

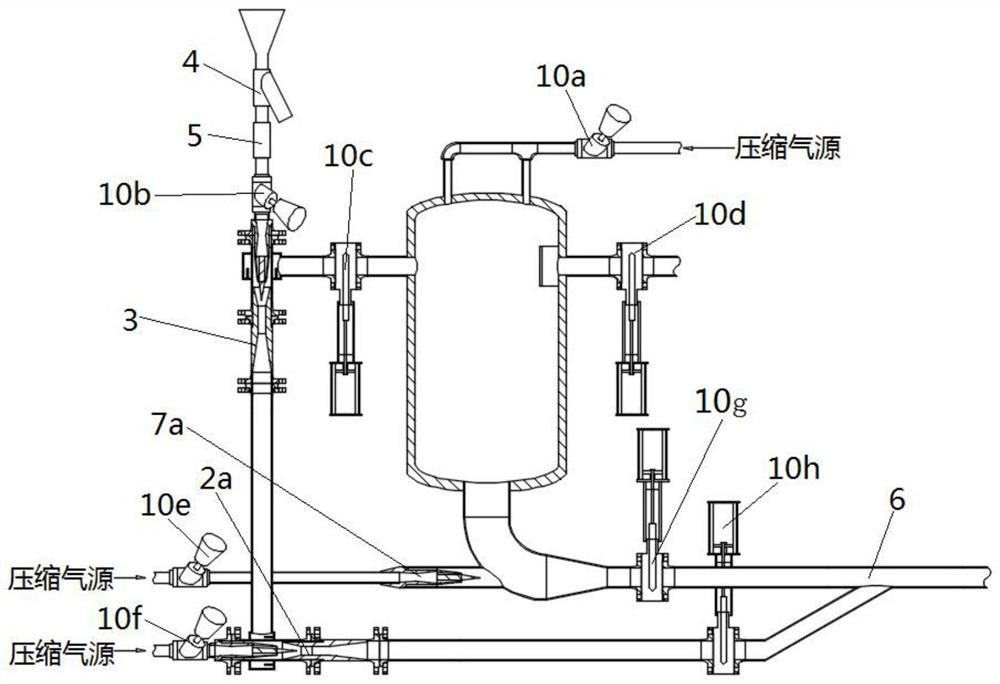

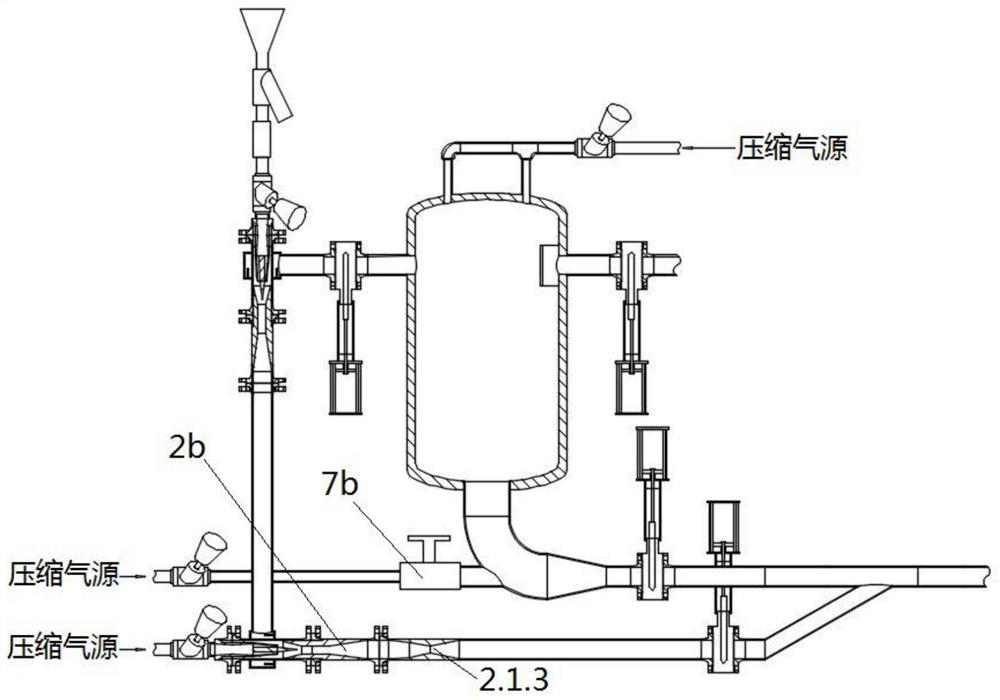

[0040] see Figure 1 to Figure 7 , a vacuum slag removal system, this embodiment is applied to the removal of silt and muck in shield tunnels.

[0041]A vacuum slag discharge system, comprising a slag storage unit, a negative pressure slag suction unit, a positive pressure air supply unit, a slag discharge unit and a compressed air source; the positive pressure air supply unit is respectively connected to the slag storage unit and the compressed air source; The negative pressure slag suction unit is connected to the compressed air source; the negative pressure slag suction unit and the slag discharge unit are both connected to the slag storage unit; the slag storage unit, negative pressure slag suction unit, positive pressure air supply unit, exhaust The slag unit includes a pressure gauge 9 and a valve 10 to monitor the pressure of the vacuum slag discharge system; and to control the on-off of each connecting pipeline.

[0042] see Figure 1 to Figure 3 , the slag storage u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com