Ignition method and device for cutting gun

A technology of cutting torch and bypass device, which is applied to igniter with fuel, combustion ignition, combustion method, etc., can solve the problems of poor coordination, premature ignition, large space, etc., and achieve simple ignition method and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through embodiment now in conjunction with accompanying drawing.

[0016] The ignition method of the present invention is to set a bypass channel on the gas supply channel of the cutting torch to provide a small amount of gas and a very small amount of gas needed for the torch to maintain a soybean oil lamp type eternal flame for the cutting torch in a non-working state when the cutting gas is cut off. of high pressure oxygen. The method is realized by automatic control system control.

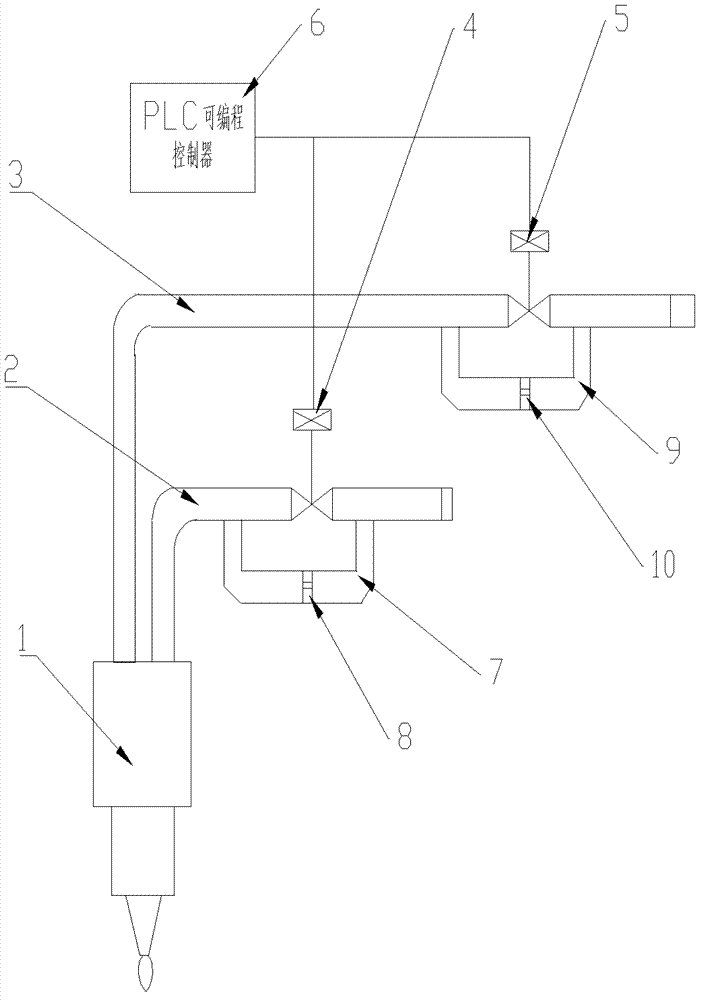

[0017] The ignition device of the present invention is shown in the figure, the gas supply pipeline 2 and the high-pressure oxygen supply pipeline 3 of the torch 1 are respectively connected with a solenoid valve 4 to control the supply of gas or high-pressure oxygen for the cutting work of the torch . The gas solenoid valve 4 and the high-pressure oxygen solenoid valve 5 are respectively connected to the PLC programmable controller 6 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com