Acoustic wave agglomeration chamber for PM2.5 particulate matters in industrial flue gas and emission reducing device thereof

A technology for industrial flue gas and particulate matter, which is used in combination devices, gas treatment, and dispersed particle separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

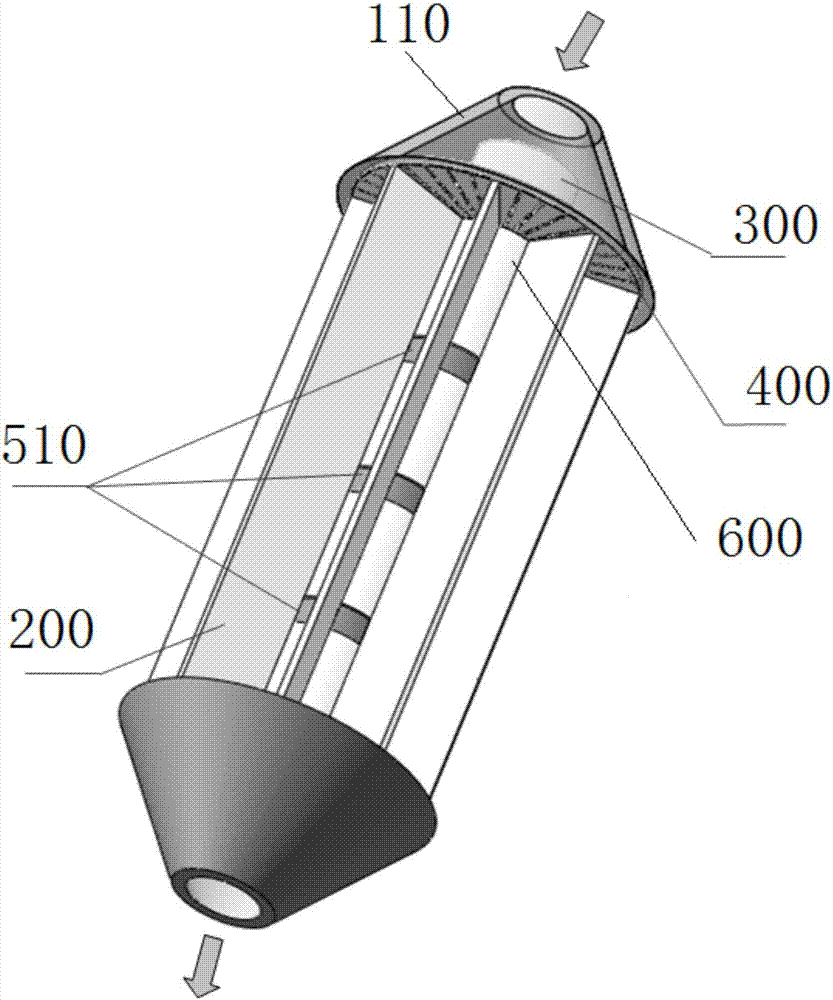

[0030] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

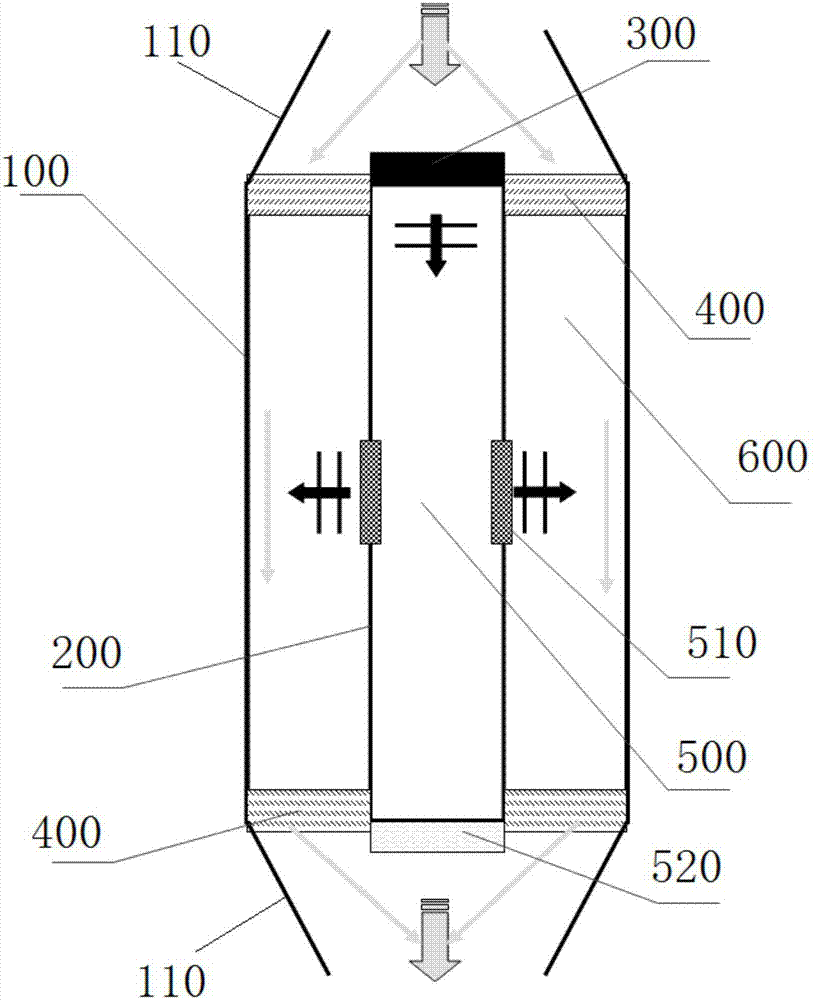

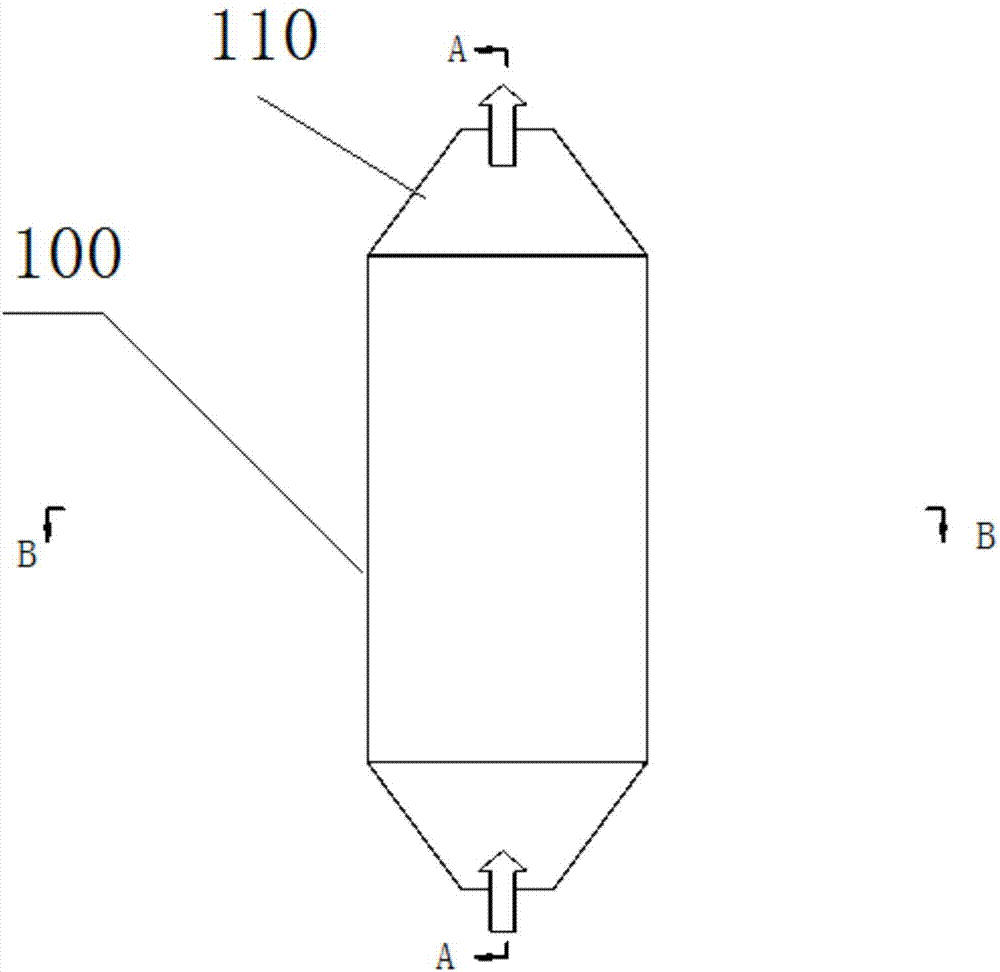

[0031] see figure 1 The acoustic agglomeration chamber for PM2.5 particulate matter in industrial flue gas provided by the present invention includes a cylinder body 100, a standing wave partition 200, and an airflow intensity sound source 300 for radiating sound waves into the cylinder body 100, and the two ends of the cylinder body 100 are respectively For the smoke inlet and the smoke outlet, the two ends of the cylinder 100 are respectively provided with smoke-permeable sound-resistance structures 400; the standing wave partition 200 is inserted in the cylinder 100, and the cylinder 100 is divided into multiple The axis of 100 is the standing wave tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com