Method for reducing emission of flue gas carbonic anhydride of fire coal electric power plant and recycle, and special system thereof

A carbon dioxide, coal-fired power station technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of not mastering the design and manufacturing technology of large-scale flue gas carbon dioxide emission control devices, and achieve a high degree of completeness of the reaction. , Wide application prospects, the effect of adapting to a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

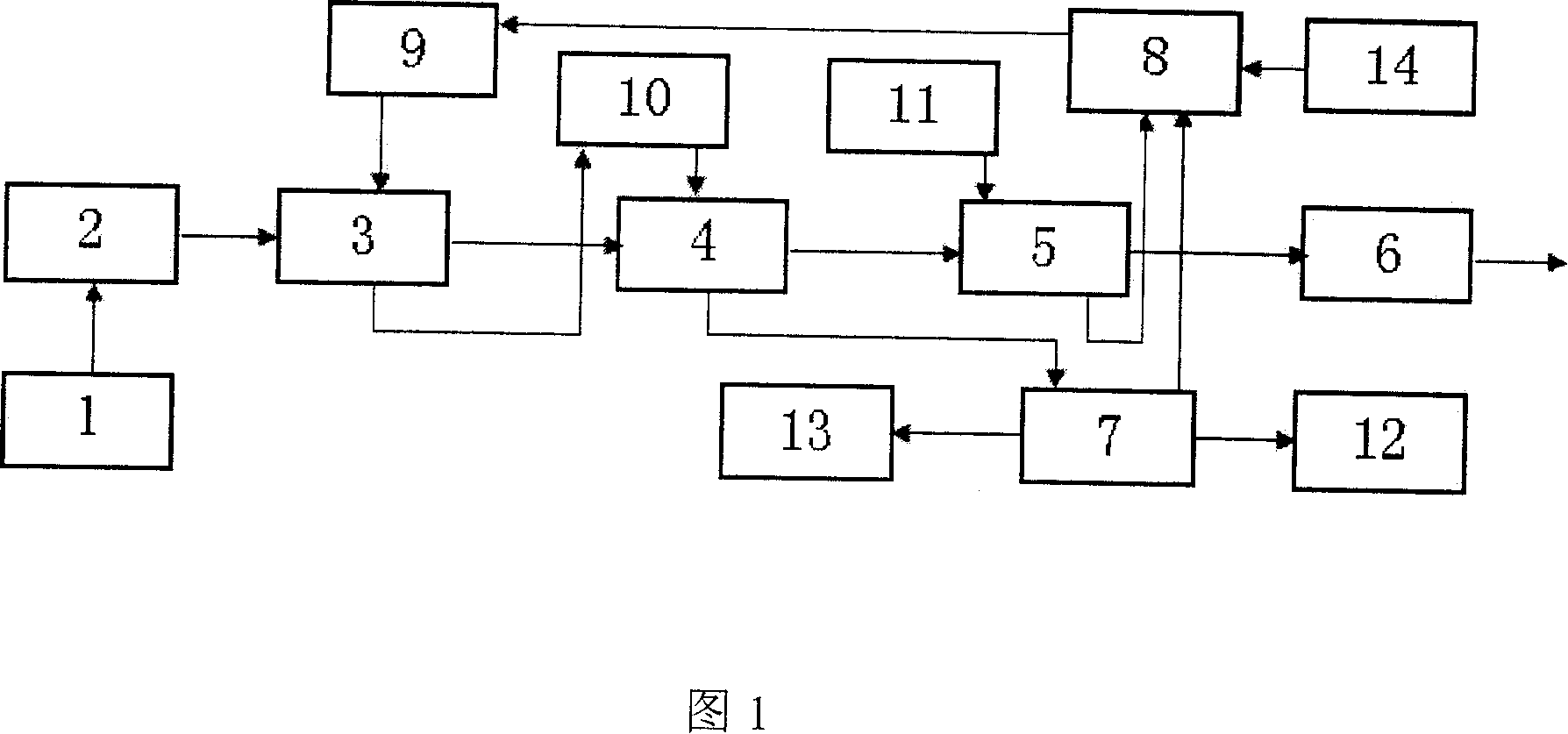

[0034] A coal-fired power plant boiler discharges flue gas of 170,000 cubic meters per hour, and the carbon dioxide content in the flue gas is 15%. In the three-tower absorption device, 17.5% ammonia solution is used as the absorbent, and the molar ratio of ammonia to carbon dioxide is 1.6. The specific process is:

[0035] The ammonia solution is sprayed by the ammonia material circulation device I (8), II (9), III (10) to the main and auxiliary absorption towers (3) and (4) entering the carbon dioxide absorption system to absorb the carbon dioxide in the flue gas that has been pre-dust removed Afterwards, enter the multifunctional separation device (7) and enter the amino substance circulation device III (10) after separation; the ammonia and dust etc. that are washed by clear water in the cleaning tower enter the amino substance circulation device III (10); The former amino substance storage device (14) replenishes to the amino substance circulation device (10) to continue ...

Embodiment 2

[0037]A coal-fired power plant boiler discharges 485,000 cubic meters of flue gas per hour, and the carbon dioxide content in the flue gas is 14%. In the three-tower absorption device, 20% ammonia solution is used as the absorbent, and the molar ratio of ammonia to carbon dioxide is 1.8. The specific process is:

[0038] The ammonia solution is sprayed by the ammonia material circulation device I (8), II (9), III (10) to the main and auxiliary absorption towers (3) and (4) entering the carbon dioxide absorption system to absorb the carbon dioxide in the flue gas that has been pre-dust removed Afterwards, enter the multifunctional separation device (7) and enter the amino substance circulation device III (10) after separation; the ammonia and dust etc. that are washed by clear water in the cleaning tower enter the amino substance circulation device III (10); The former amino substance storage device (14) replenishes to the amino substance circulation device III (10) to continue...

Embodiment 3

[0040] A coal-fired power station boiler discharges flue gas of 305,000 cubic meters per hour, and the carbon dioxide content in the flue gas is 14%. In the three-tower absorption device, 15% ammonia solution is used as the absorbent, and the molar ratio of ammonia to carbon dioxide is 1.5. The specific process is:

[0041] The ammonia solution is sprayed by the ammonia material circulation device I (8), II (9), III (10) to the main and auxiliary absorption towers (3) and (4) entering the carbon dioxide absorption system to absorb the carbon dioxide in the flue gas that has been pre-dust removed Afterwards, enter the multifunctional separation device (7) and enter the amino substance circulation device III (10) after separation; the ammonia and dust etc. that are washed by clear water in the cleaning tower enter the amino substance circulation device III (10); The former amino substance storage device (14) replenishes to the amino substance circulation device III (10) to conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com